Technology | 10.03.2025

YCM: JC Series of High-Performance Vertical Machining Centers

By: Hebert Garza

10.03.2025

Share

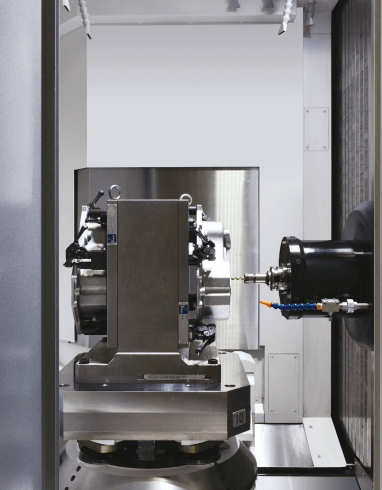

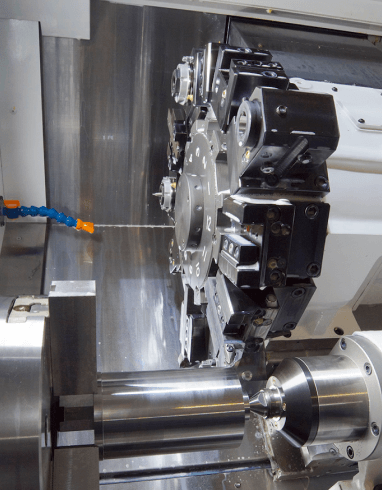

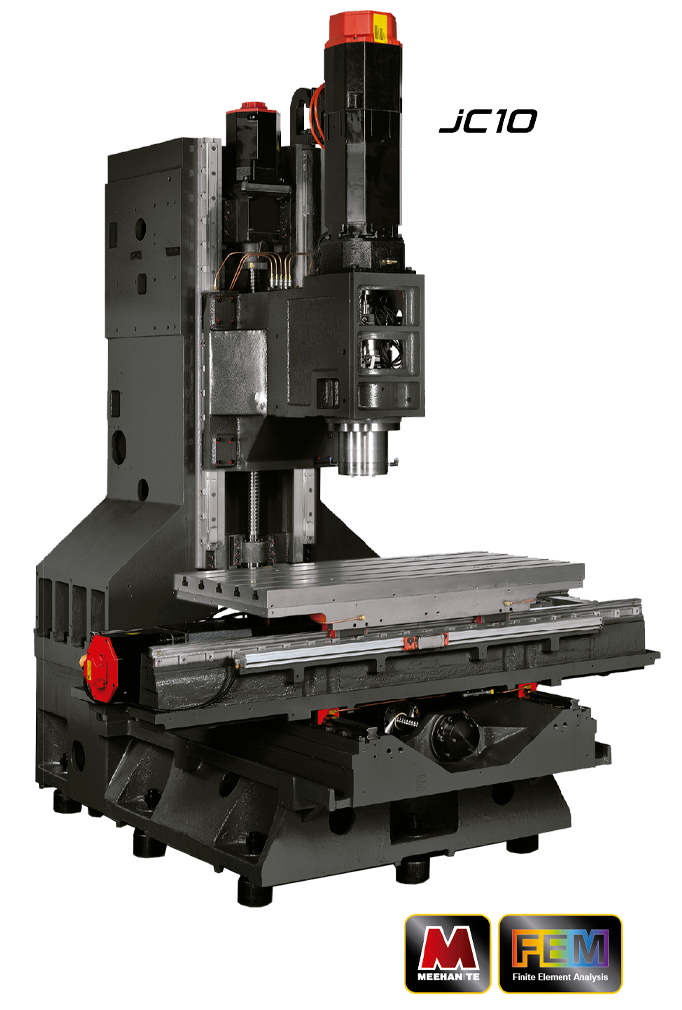

There is a wide and diverse offer of vertical CNC Machining Centers and CNC lathes in the market, however, not all manufacturers offer quality and technology in an entry-level price range. YCM came to Mexico to redefine these terms through its JC series, which offers top quality at an excellent value-quality rate.

Each YCM CNC Machine Tool is built and handcrafted for rigidity, thermal stability, and repeatability. In addition, it produces consistent, high-quality results from the first part to the last, on equipment that surpasses the capabilities of other brands.

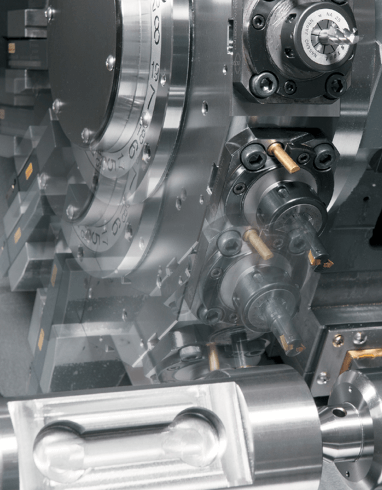

vertical cnc machining centers/vertical cnc machining centers

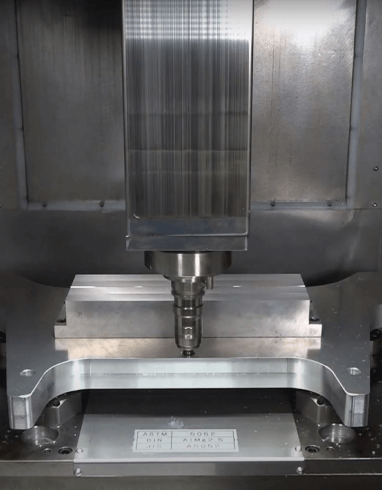

Quality, precision and speed

During the design process, YCM uses a method called Finite Element Analysis (FEM) to ensure the best placement of mass and rib structures to provide constant stability under intensive load of heavy-duty cutting. Direct drive servo motors provide fast, accurate and repeatable cutting. Each axial AC servo motor is equipped with positioning encoders that, combined with rigid body construction, provide a combination of uncompromising precision and stiffness.

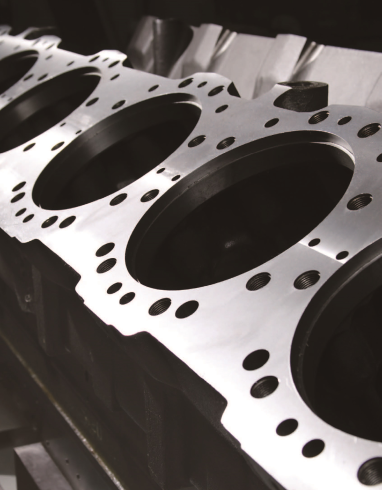

Real manufacturers

Unlike other machine tool manufacturers thar simply assemble their equipment, YCM is a true CNC machine tool builder. This commitment to quality begins at the YCM foundry, where the heart of every machine – the base, is perfectly cast resulting in a rigid Meehanite casting. All mating surfaces are then hand scraped by expert craftsmen. This establishes a quality base which is precise, rigid, and very stable. This build process is inherent with every YCM machine tool produced. This process is followed by a Karl Fischer moisture and pH titration measurement, as well as an annealing and aging process to correct casting stresses.

spindle to perfection to ensure optimum performance and longevity.

vertical cnc machining centers/vertical cnc machining centers

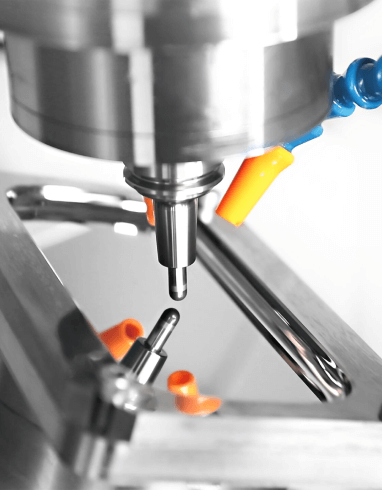

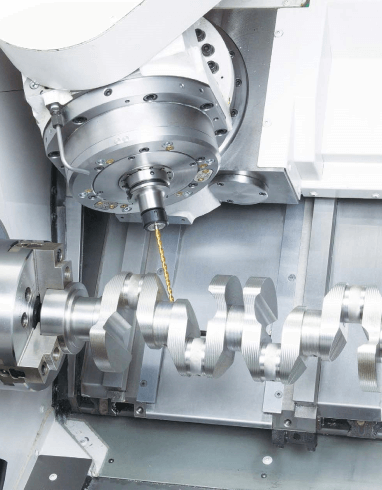

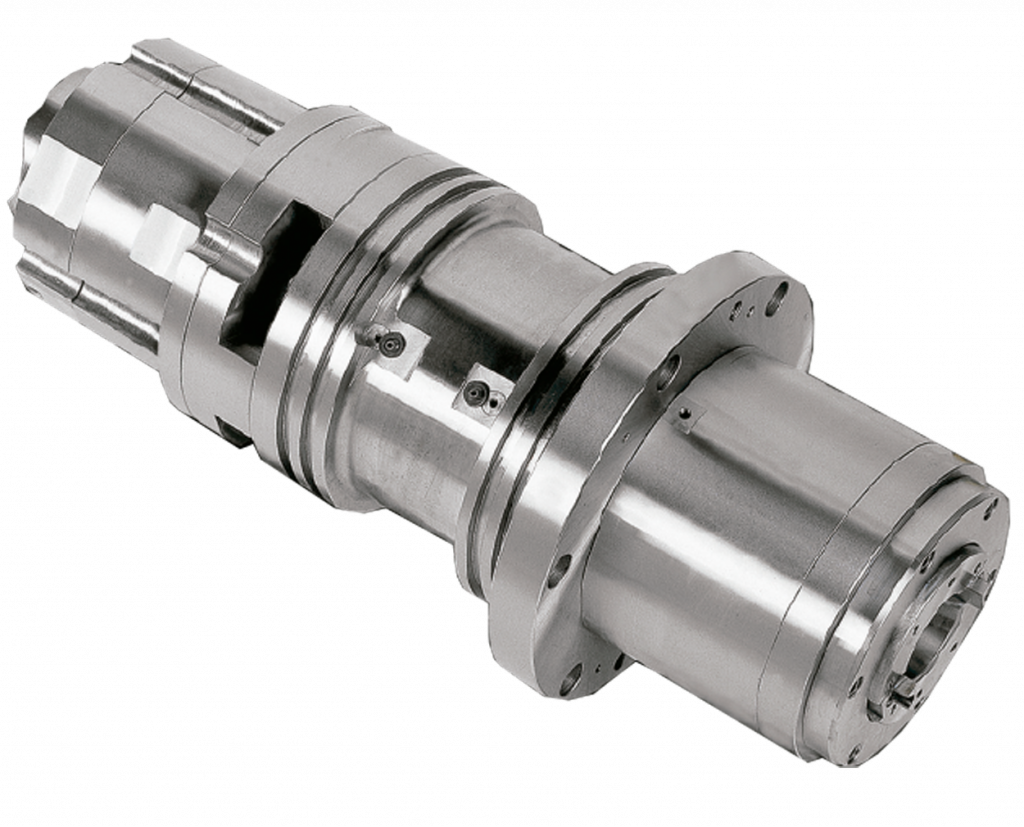

IDD Plus Spindle

The spindle is the critical link between the CNC Machining Center, the cutting tool and the workpiece. YCM designs, manufactures and tests each spindle to ensure optimum performance and longevity. Thanks to these quality standards the JC series gains versatility, whether you’re manufacturing parts for the automotive, aerospace, medical or energy industries, the IDD Plus Spindle has you covered.

YCM MXP 200FB+

The best Vertical CNC Machining Centers

Finally, we must talk about the CNC Control of the JC Series, the YCM MXP 200FB+ operating system. This runs in a FANUC 0iMF+ platform on a 10.4-inch LCD display with USB, Compact Flash cards and RJ45 Ethernet ports, as well as an integrated QWERTY keyboard. In addition, YCM’s unique operating system features:

– AICC II+, high precision and accuracy AI contour control

– Smooth Tolerance control+

– Machining quality level adjustment function

– Maximum 400 blocks of lock-ahead for pre-calculating the machining program

– Block processing time 1ms for achieving high-speed machining requirement

– Smart rigid tapping function combined with spindle capability for high-speed machining

– Manual Guide I features dynamic simulation of machining programs with full-screen display

– 2 MB program storage

– Built-in memory card for easy program editing

– Directory filing structure with organized file management

– 400 pairs of offset tools, 1,000 recordable programs, 48 pairs of workplace coordinate system, 256 pairs of tool life management

To learn more about TEQNIPRO by HEMAQ YCM equipment, click here.