Industry | 12.08.2024

Developing human talent, a safe bet

By: Hebert Garza

12.08.2024

Share

With the growth of the manufacturing industry in Mexico and Latin America, there are great job opportunities for those interested in the vast world of CNC operation and programming. And although it may seem counterintuitive, the demand for operators and technicians has grown so much that, in cities with high industrial production, such as Monterrey, Querétaro, León and Saltillo, salaries and benefits are higher for those involved in CNC machining, than those for professionals with undergraduate diplomas.

Following the 2020 pandemic, the nearshoring boom and the growing wave of manufacturing in Mexico, the metal-mechanic industry in Mexico has received large investments from abroad; an example of this was the sustained growth that began since 2021 with an investment of US$4.8 million, which represented a growth of 36.1 % over the previous year.

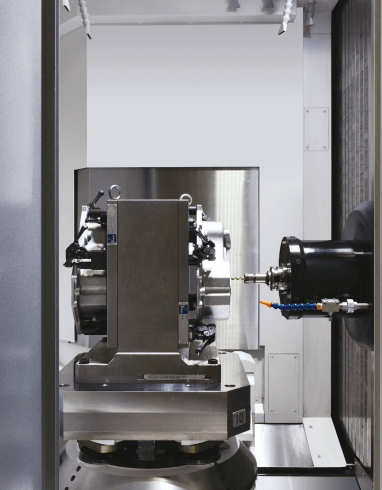

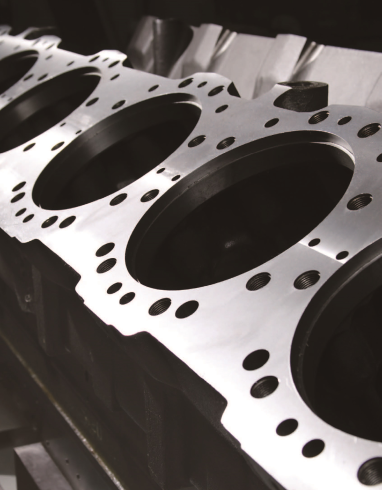

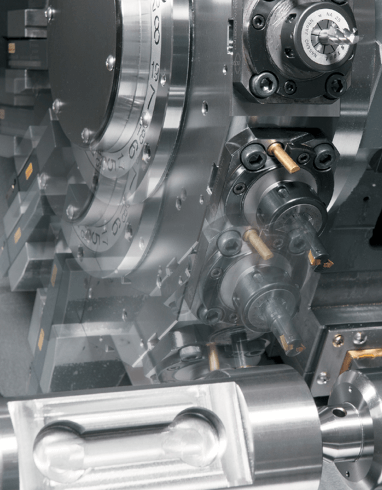

Likewise, according to data from INEGI’s “Directorio En México Estadístico Nacional de Unidades Económicas” (Directory In Mexico National Statistical Directory of Economic Units or DENUE), in 2023 there were 2,800 companies dedicated to the manufacture of parts for machinery and equipment, as well as almost 10 thousand manufacturers of metal parts and screws, which undoubtedly require skilled labor in the operation of machinery such as lathes, milling machines and CNC Machining Centers.

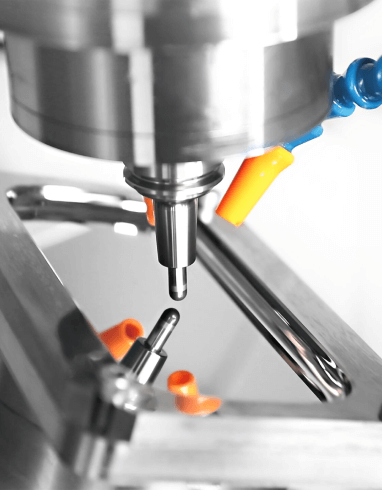

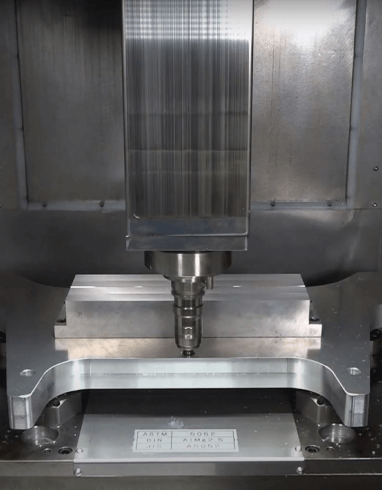

This panorama leads us to a clear conclusion: the need to keep our human talent trained and in constant professional growth, not only to retain manpower, but also to favor a work environment where each employee can find his or her maximum potential. In response to this is that our Engineering department offers specialized courses for CNC operation and programming, some of them are:

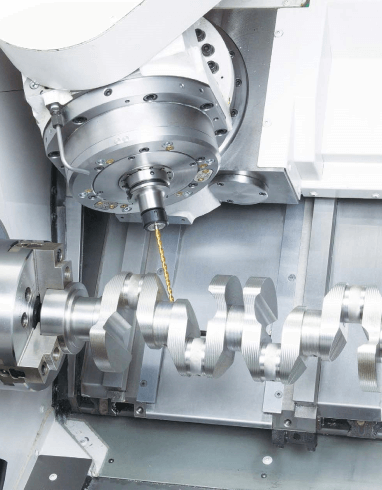

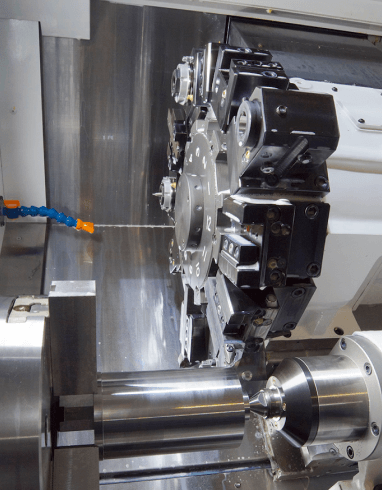

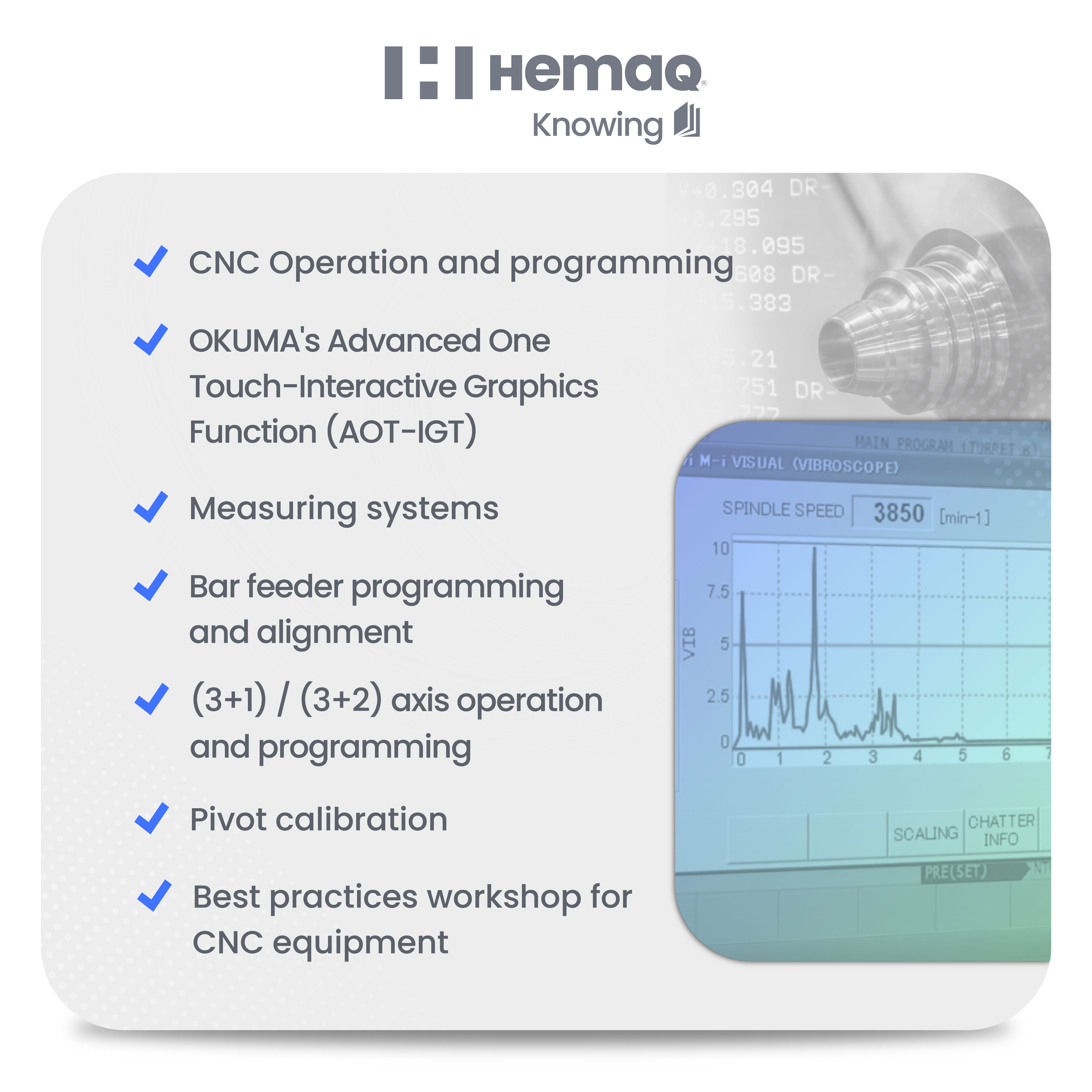

- Operation and programming from basic to advanced level for Machining Centers, Lathes and Grinding Machines.

- Okuma’s Advanced One Touch-Interactive Graphics Function (AOT-IGT) interactive programming.

- Programming and calibration of measuring systems

- Bar feeder programming and alignment

- Pivot calibration on 5-axis machines

- (3+1) / (3+2) axis operation and programming

- Best practices workshop for CNC equipment

Do not hesitate to contact our engineers to provide you with the training or course best suited to your needs.