Industria | 11.06.2024

ECO SUITE PLUS: the innovative eco-friendly system from OKUMA

By: Hemaq

11.06.2024

Share

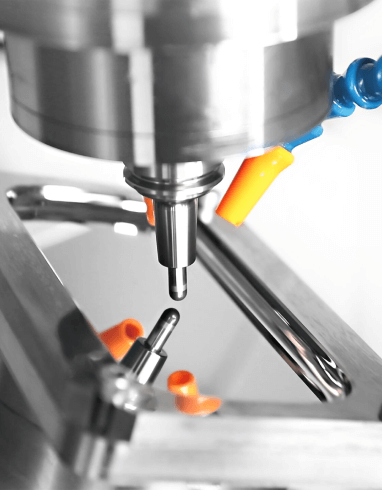

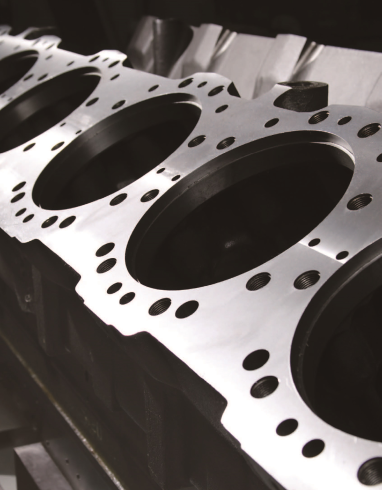

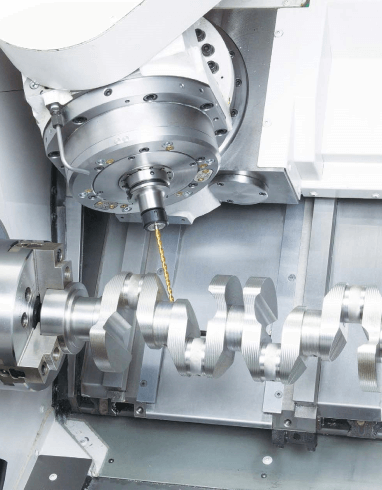

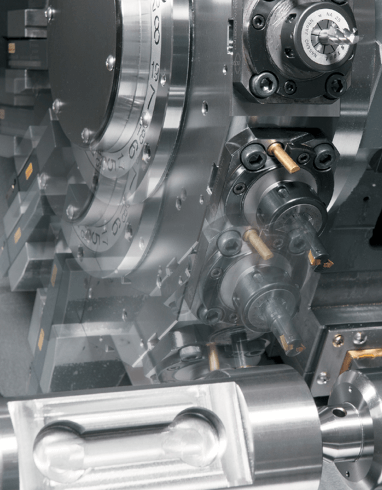

Okuma Eco Suite Plus: Okuma has a tradition of more than 40 years in the innovation of energy-saving technologies. From the development and production of its own OSP control in 1963, through the Thermo-Friendly Concept and the renewed ECO Suite Plus unctional advantage package with reduced cycle times and the utilization of energy released during decelerations in the machining process. Thus, Okuma joins the international efforts to achieve decarbonization in metal-mechanical manufacturing processes.

Okuma has stated that among its energy goals for 2050 is to achieve carbon neutrality for all its plants and to offer its customers an accurate and consistent machining process with less energy consumption. You too can achieve new green goals and savings in energy and accessories through Okuma’s green technology.

THREE LEADING POINTS FOR OKUMA’S GREEN TECHNOLOGY

- Reduce energy during machining.

- Stopping unnecessary equipment proactively.

- Shortening cycle times.

Machine tools not only consume energy during use, but also during set-up and standby times. Through unique innovations, Okuma has succeeded in significantly reducing carbon dioxide emissions during production. In addition, machining accuracy is not affected, and lower energy consumption and shorter cycle times contribute to increased productivity.

OKUMA ECO SUITE PLUS SYSTEM

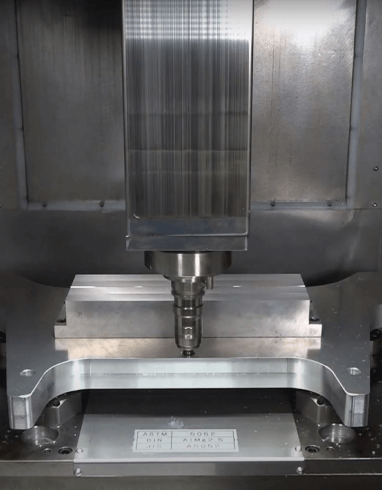

With the OSP control developed by Okuma, the operating status and carbon dioxide emissions can be recorded and analyzed with pinpoint accuracy. The accompanying visualization and integrated energy-saving functions support the energy reduction.

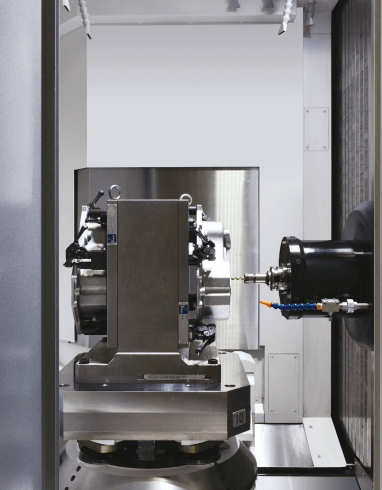

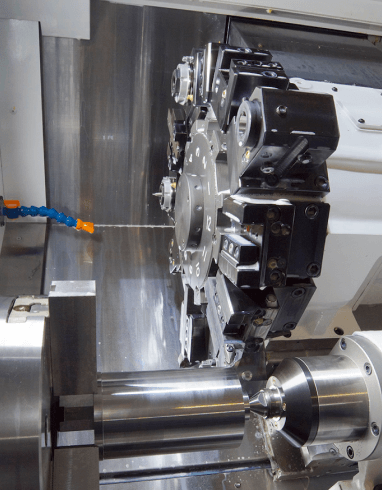

A large part of the energy consumption is accounted by all the additional devices of a machine tool. Thanks to ECO Suite Plus, the machine automatically detects the operating status of all components of the machine and puts them into an energy-saving idling mode according to need.

With the ECO Suite Plus, other peripheral devices, such as chip conveyors or extractors, can also be optionally adapted to the operation. Operation can be fine-tuned even more, as many carbon dioxide emissions as possible are reduced and energy consumption is lowered.

The highly efficient hydraulic unit significantly reduces power consumption. This means that, with a conventional hydraulic unit, the MB-4000H requires a power consumption of 840 W. With the optional ECO hydraulics, only 260 W are needed at 25 min-1.

Contact our specialized sales executives to find out how you too can achieve your green and savings goals for 2024.