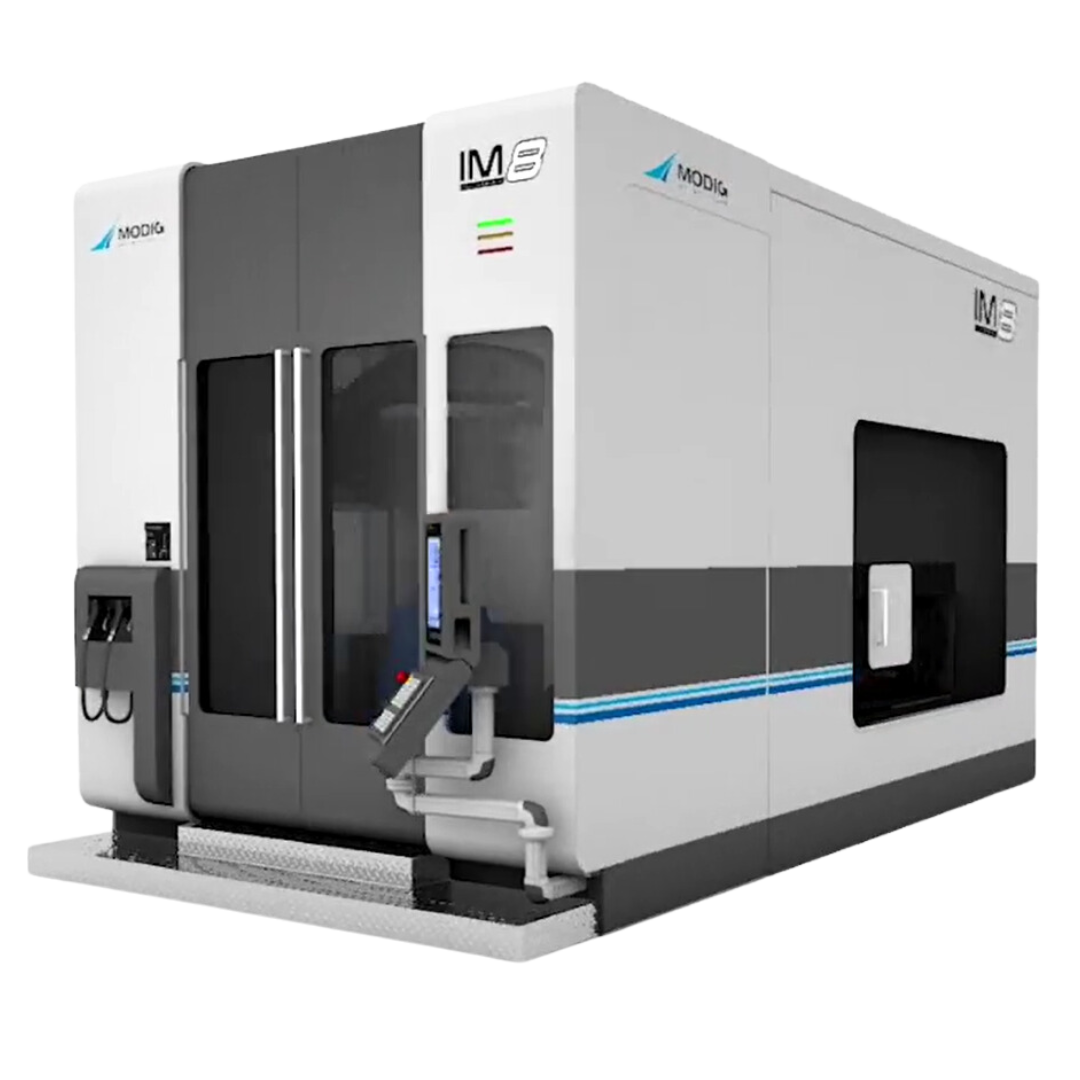

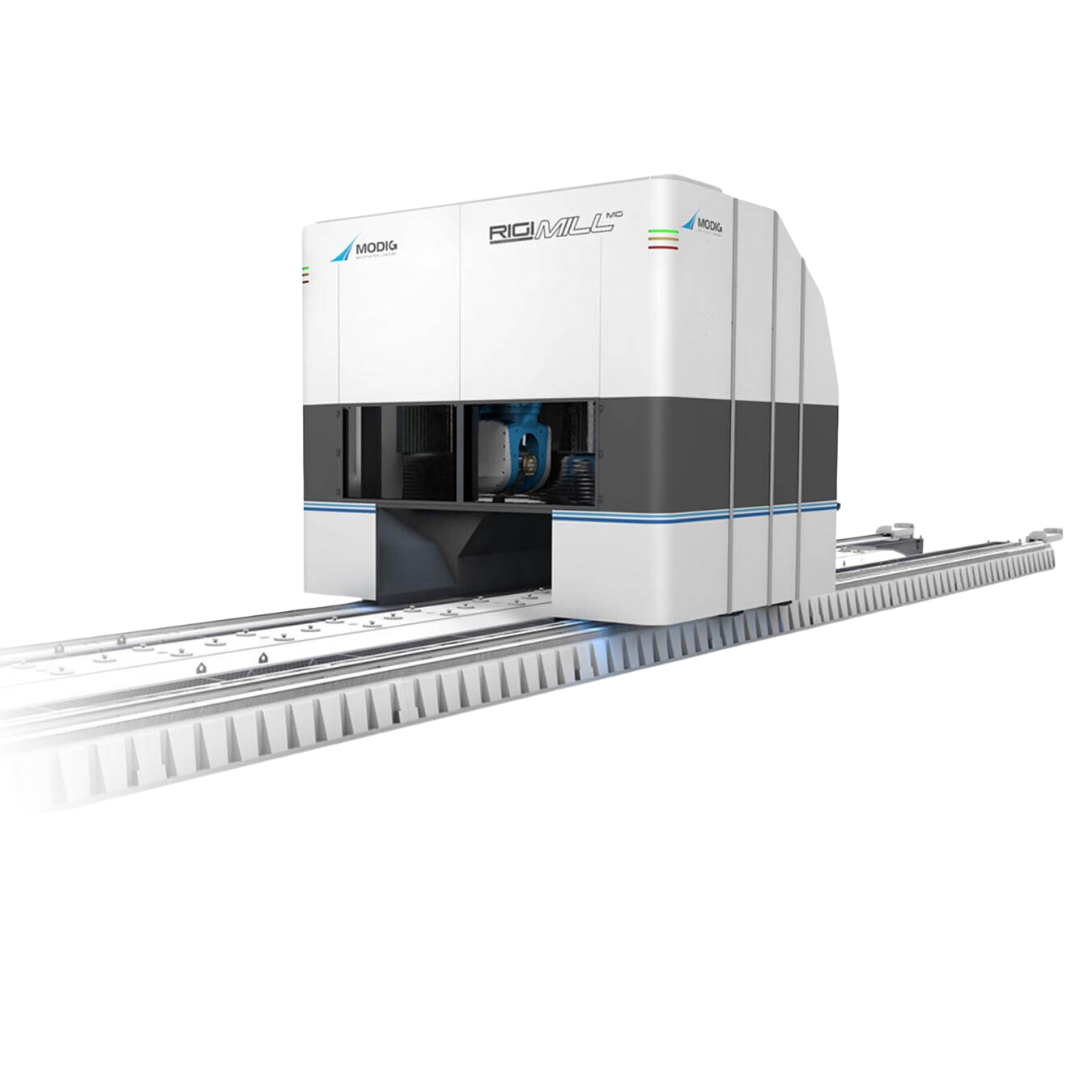

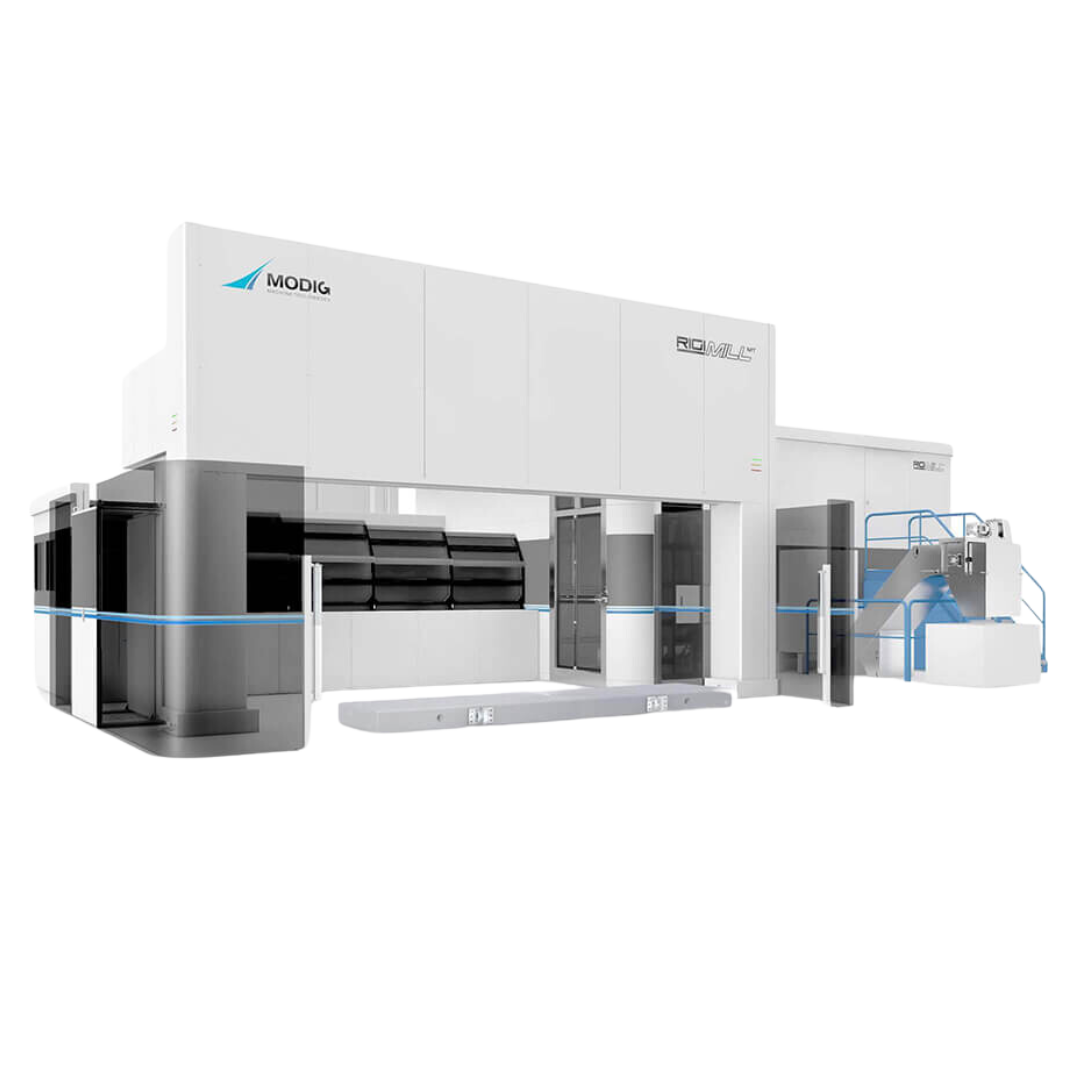

MODIG

MODIG

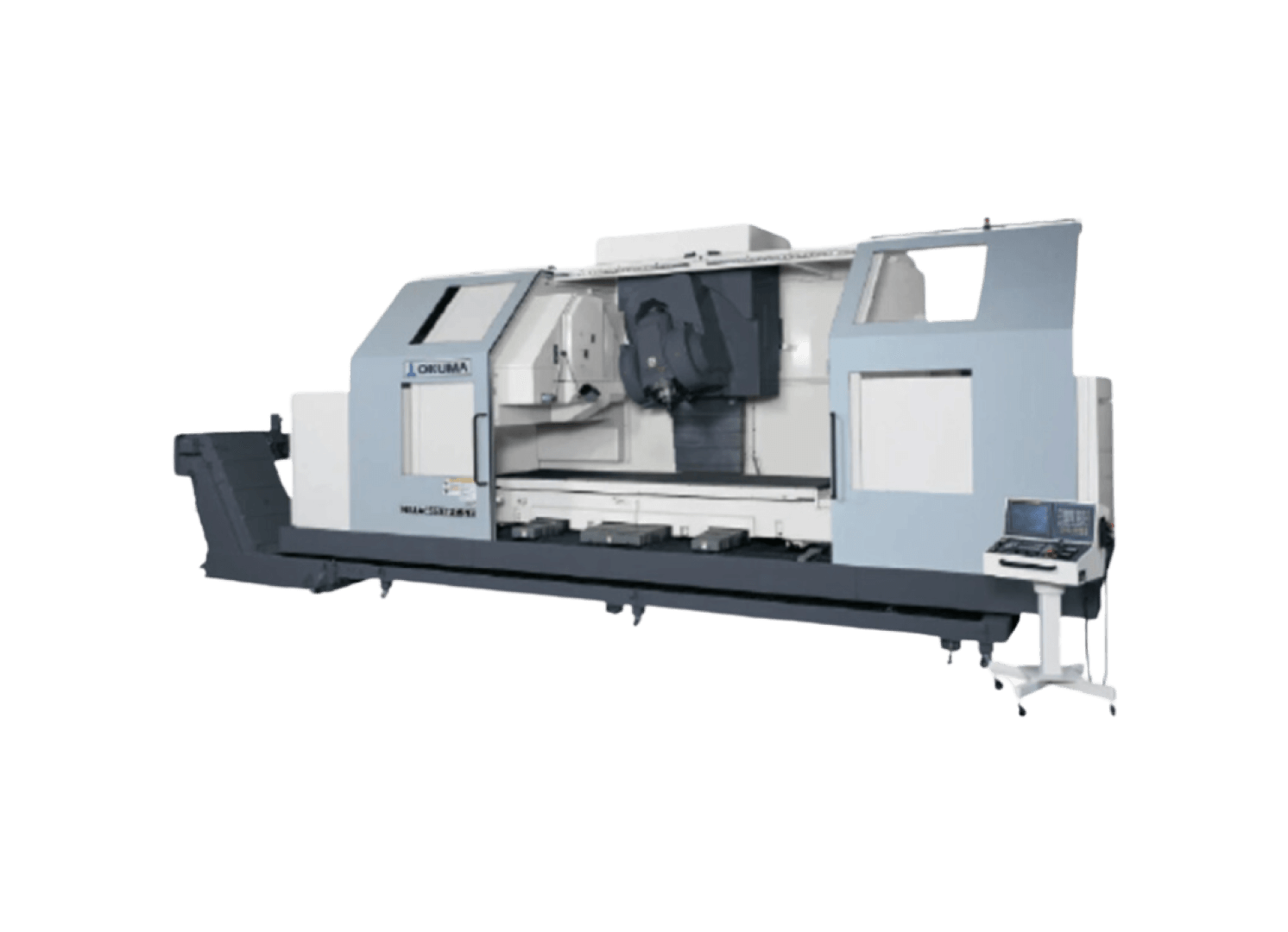

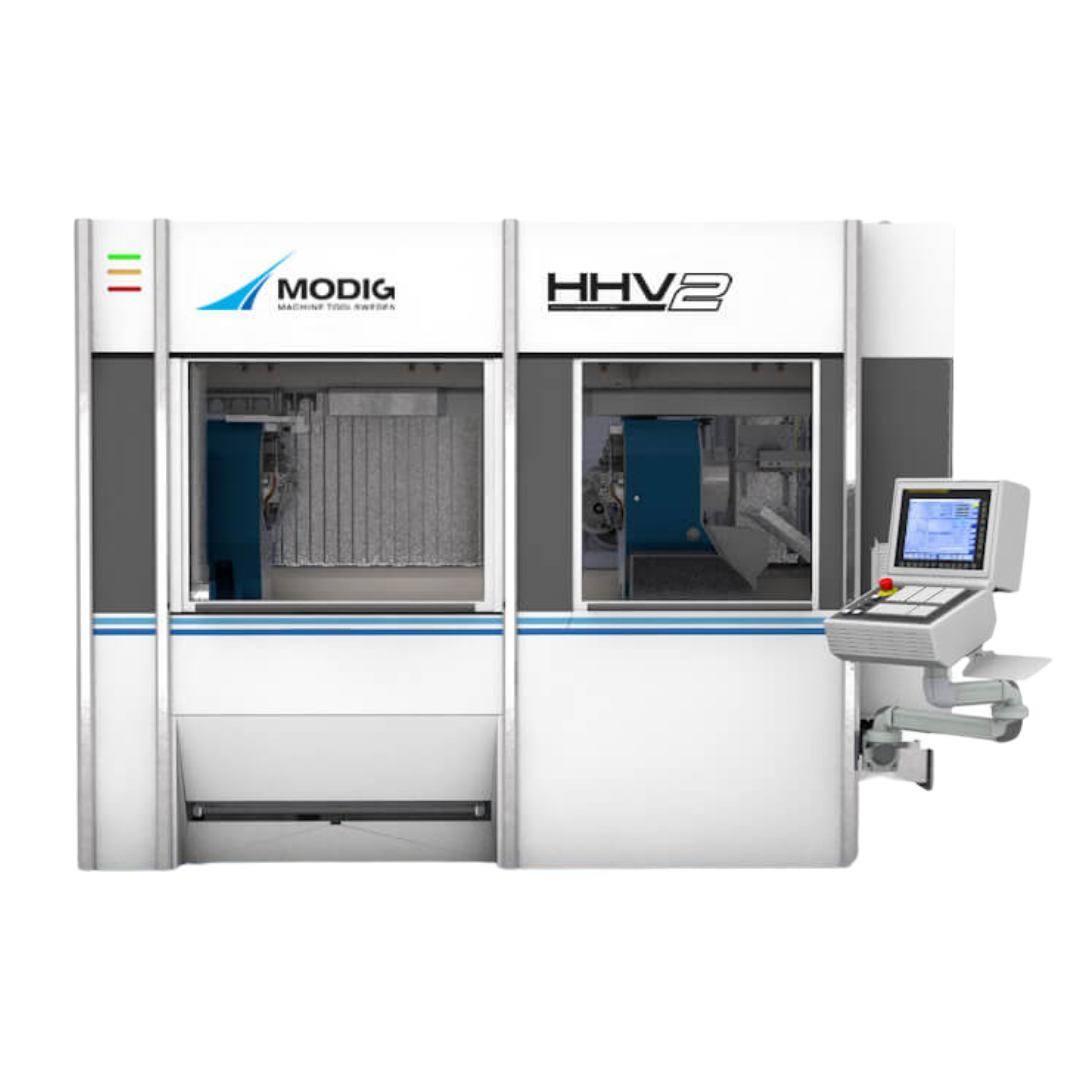

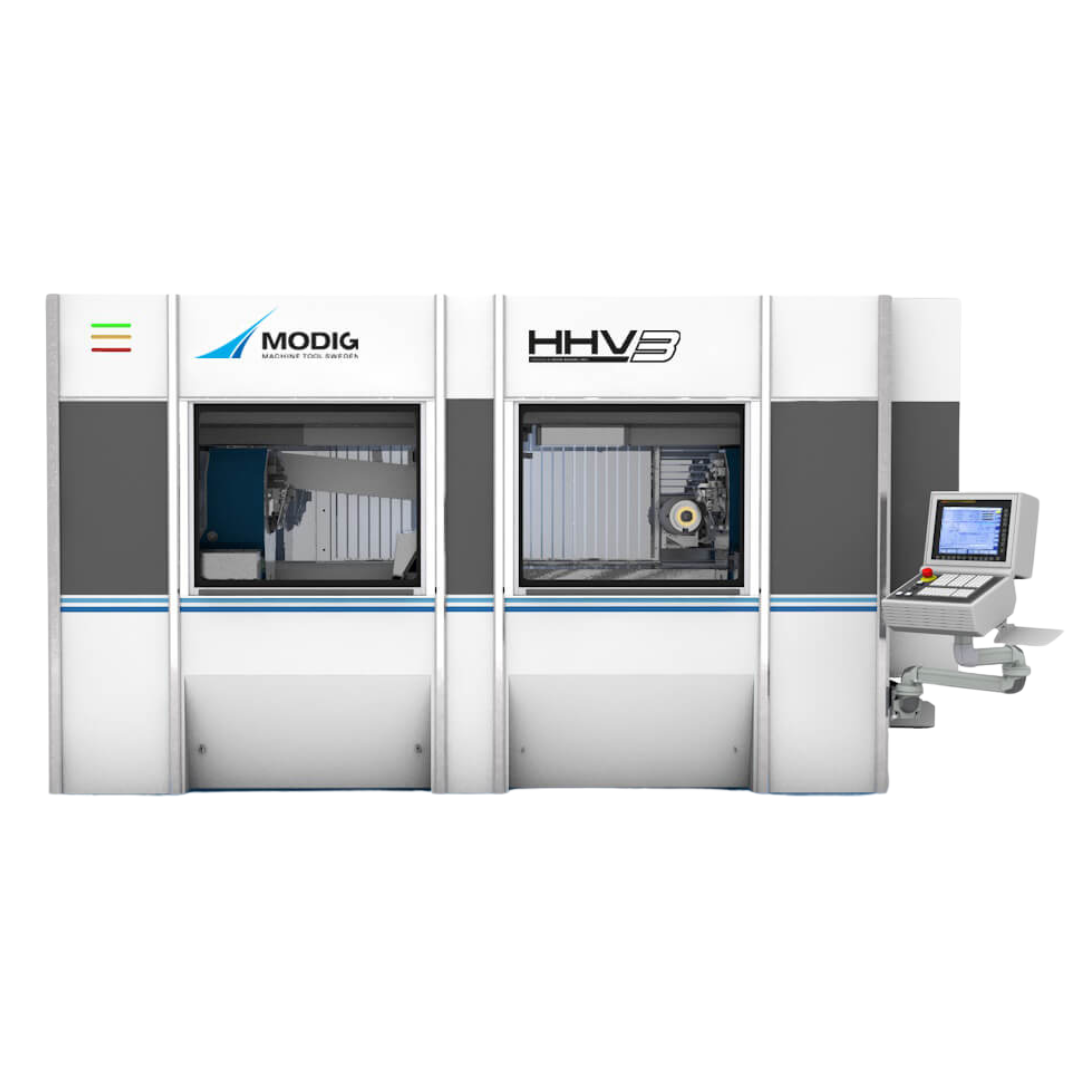

HHV3

Product description

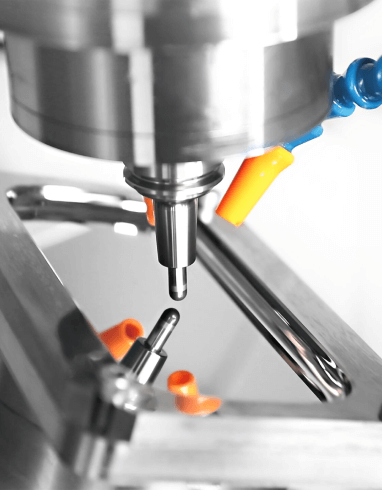

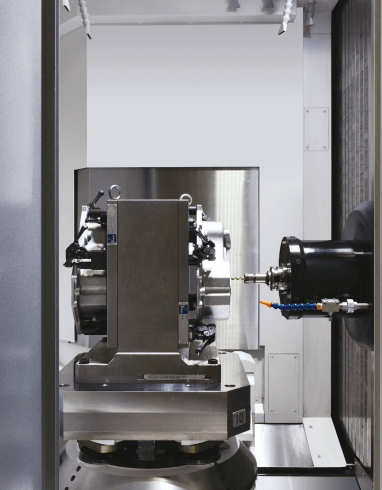

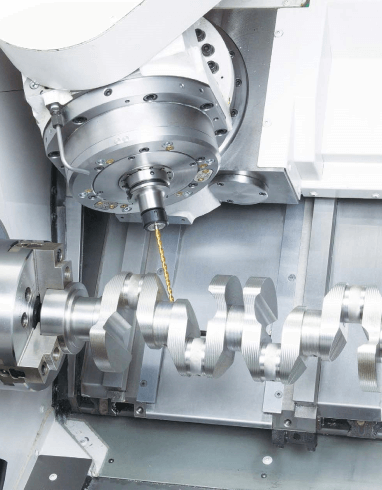

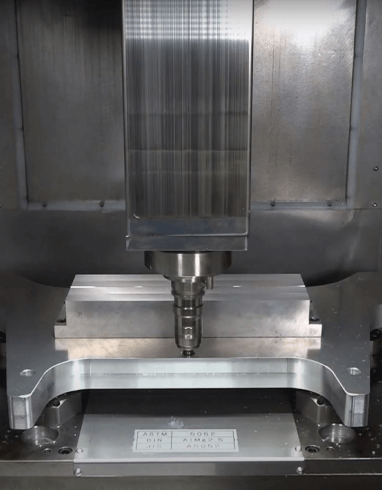

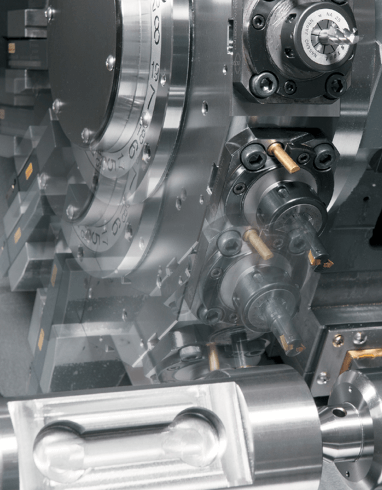

The HHV (Horizontal High Velocity) is a universal machining center for bar or extrusion components. It was developed in close cooperation with the world's largest aircraft manufacturers. Since its introduction, it quickly became the first choice of high-performance machine shops. It is ideal for repetitive short runs, nesting or high volume production. Raw material is loaded from the left side of the machine, the HHV automatically positions the raw material for machining and delivers the finished parts to a parts receiver. No pre-cutting of the raw material is required, the HHV handles uncut bars and extrusions. The benefit of manufacturing many parts from bars or extrusions of the same size is less setup time without clamping and a significant reduction in cycle time. Standard machining often requires multiple setups. Parts from HHV machines are completed in a single setup, with no rework required.

Industries

Aerospace

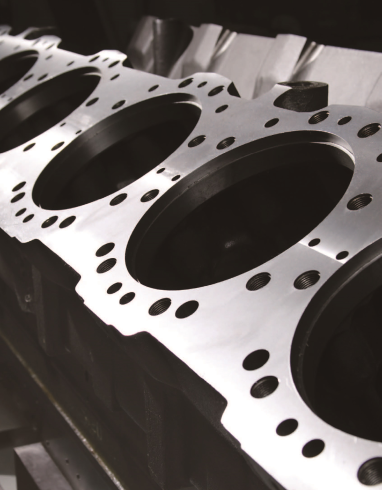

Automotive

Heavy Duty

Others

Product Highlights

Maximum cross section of the part (Bar / Extrusion) [in]Maximum cross section of the part (Bar / Extrusion) [mm]

(5 x 5) / (6 x 10)(127 x 127) / (150 x 250)

Travel (X-Y-Z / U1 / U1-U2 / A1/A2 / A3) (in)Travel (X-Y-Z / U1 / U1-U2 / A1/A2 / A3) (mm)

59-17-10 / 35 / +/-1901500-420-260 / 900 / +/-190 / +/-190

Maximum part height (in)Maximum part height (mm)

Extrusion 6 x 10 / Bar 5 x 6Extrusion 120 x 250 / Bar 127 x 127

Standard Spindle (Speed) [rpm]

30,000

Fischer Spindle

MFW-1709/30/75 VC HSK A63

Spindle speed (rpm)

30,000

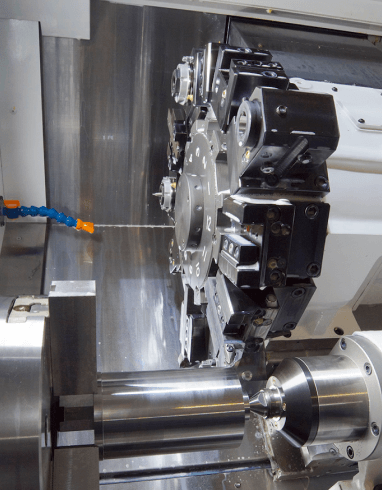

Tool Changer (# Tools)

24 to 55

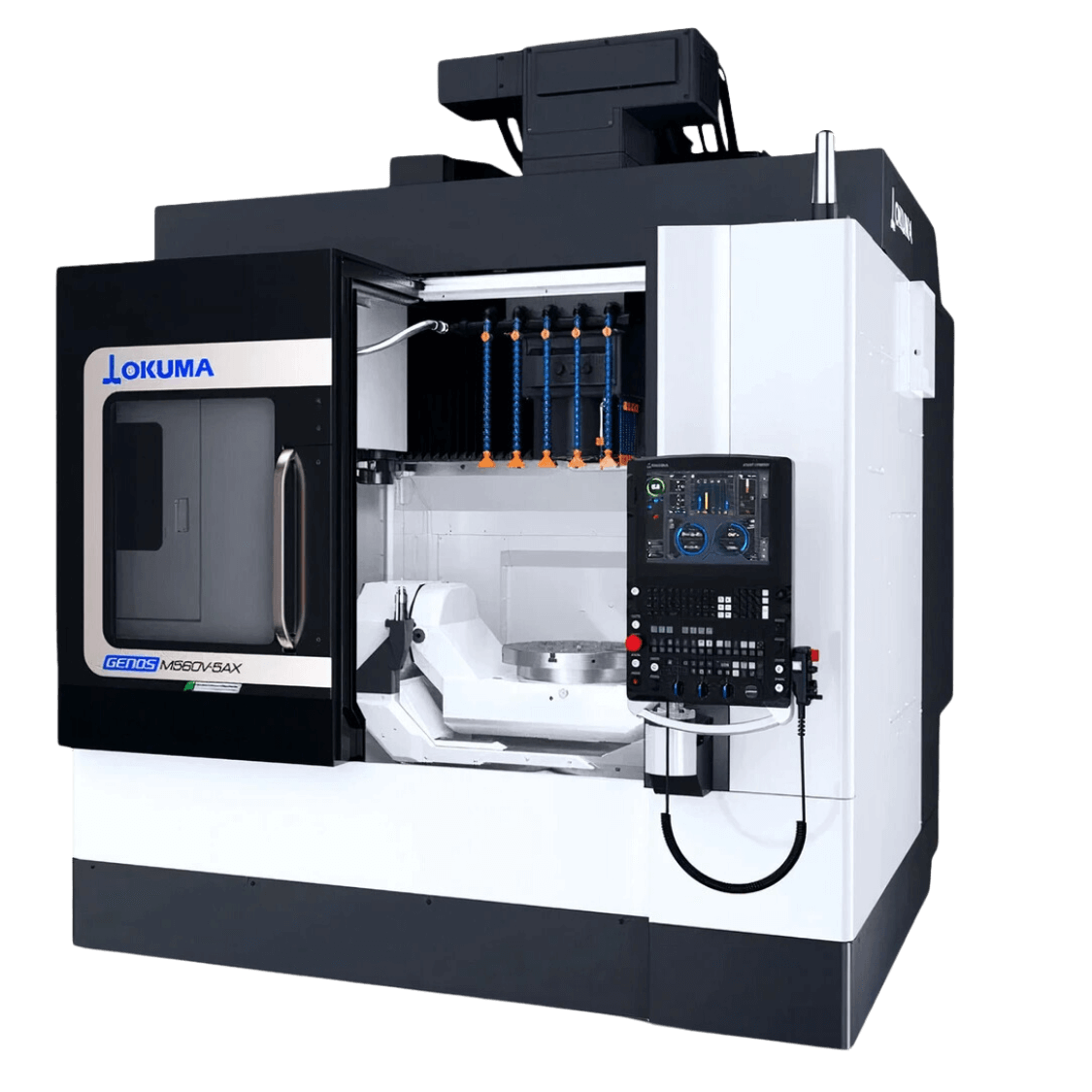

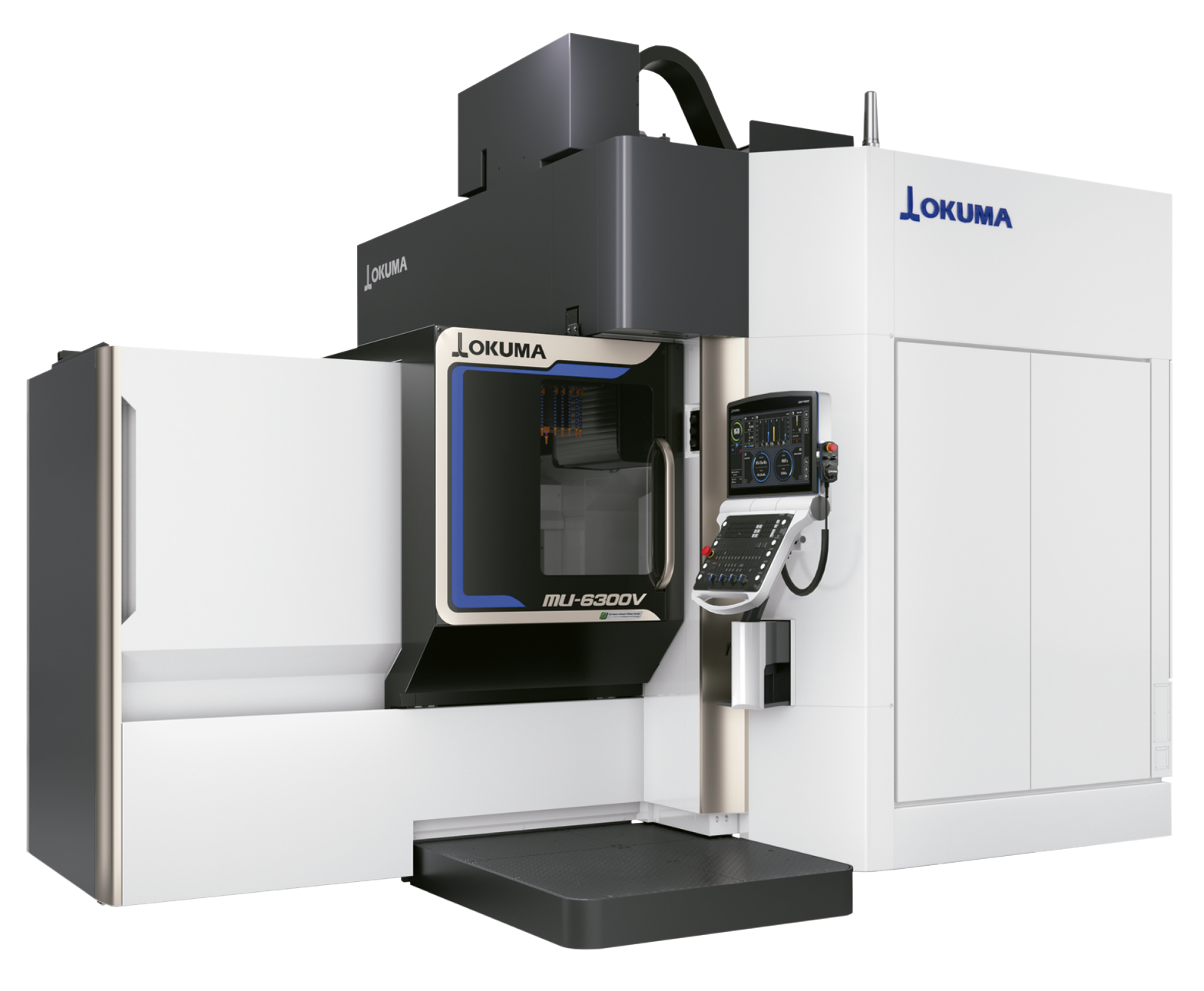

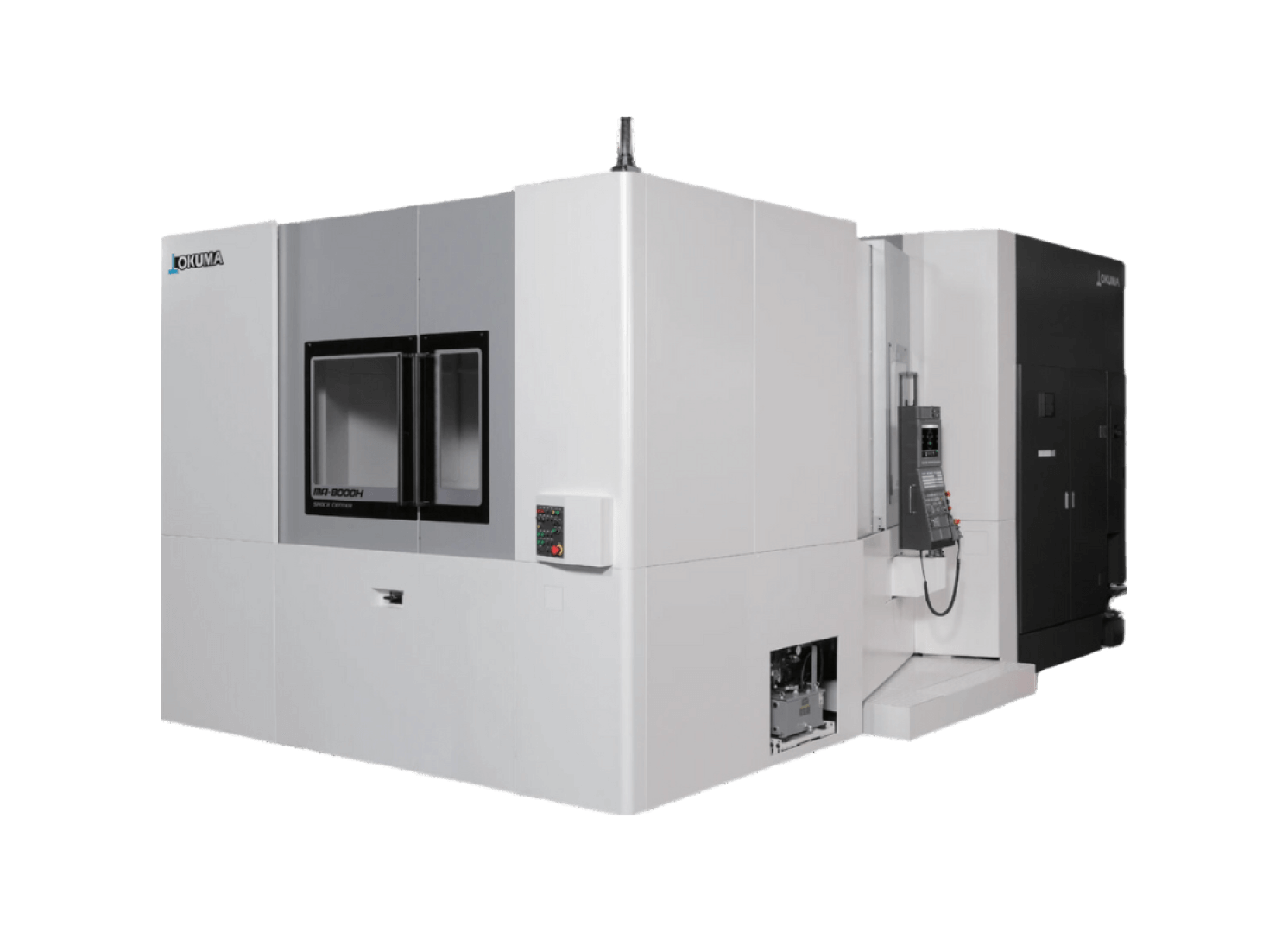

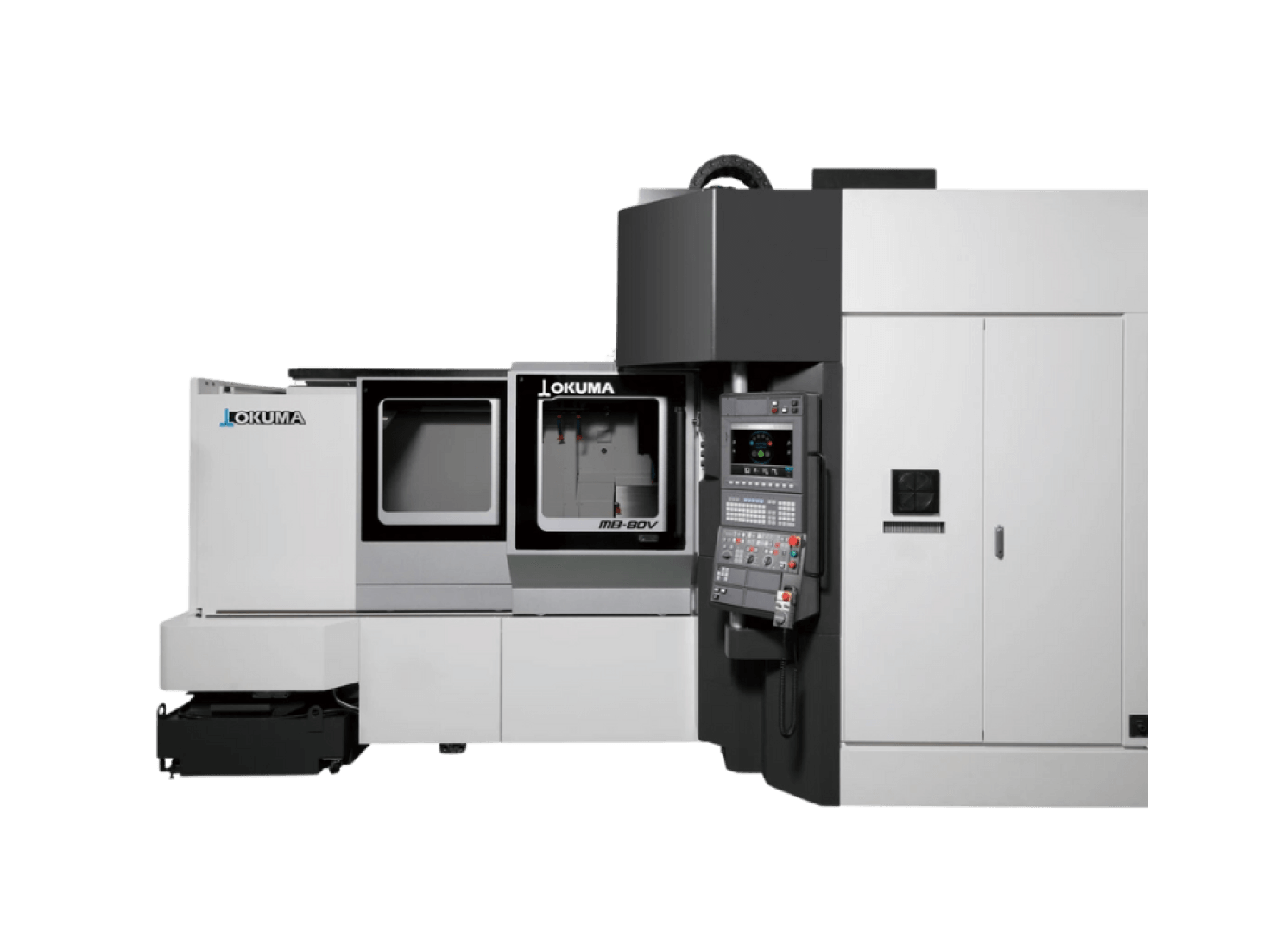

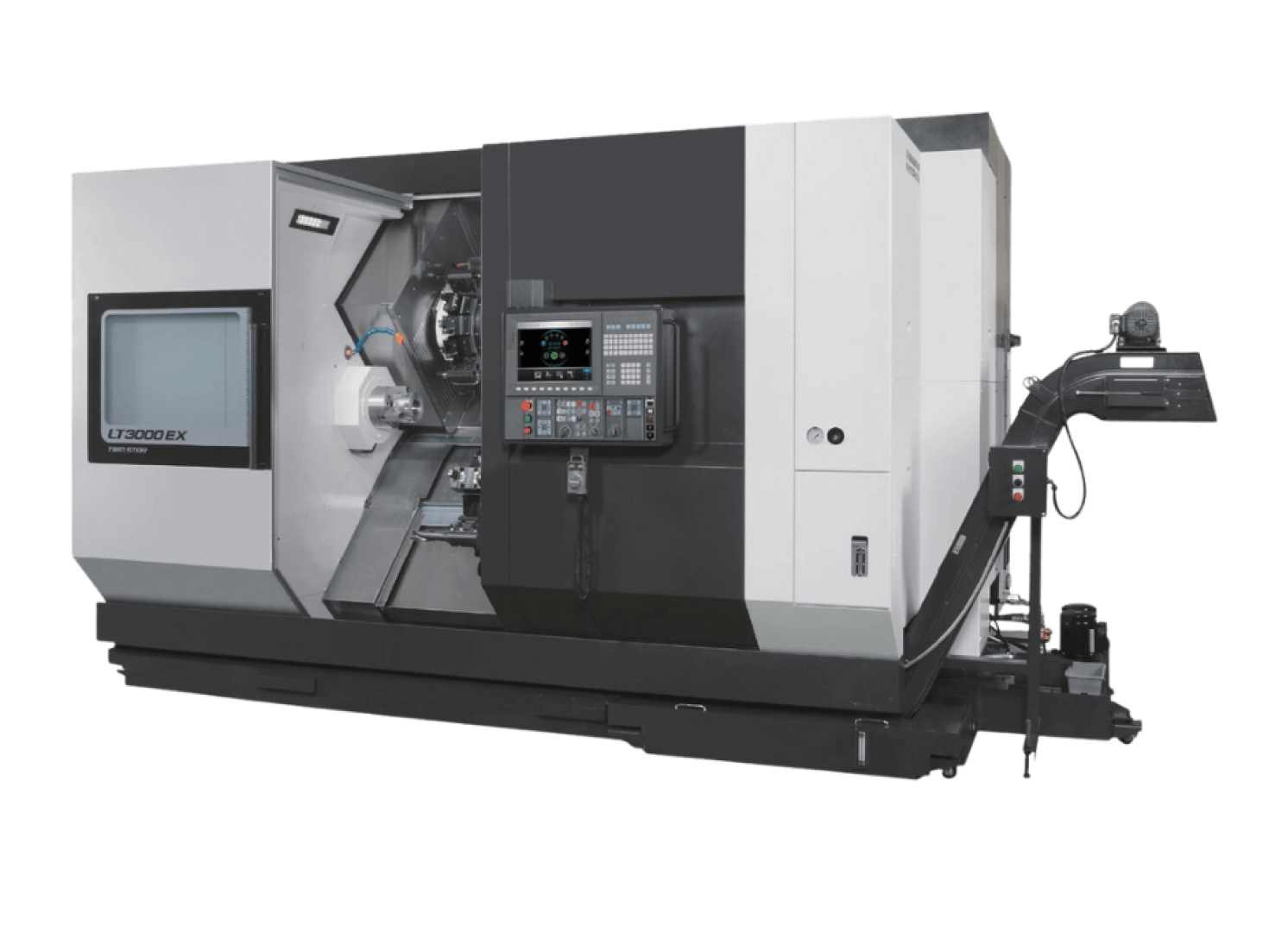

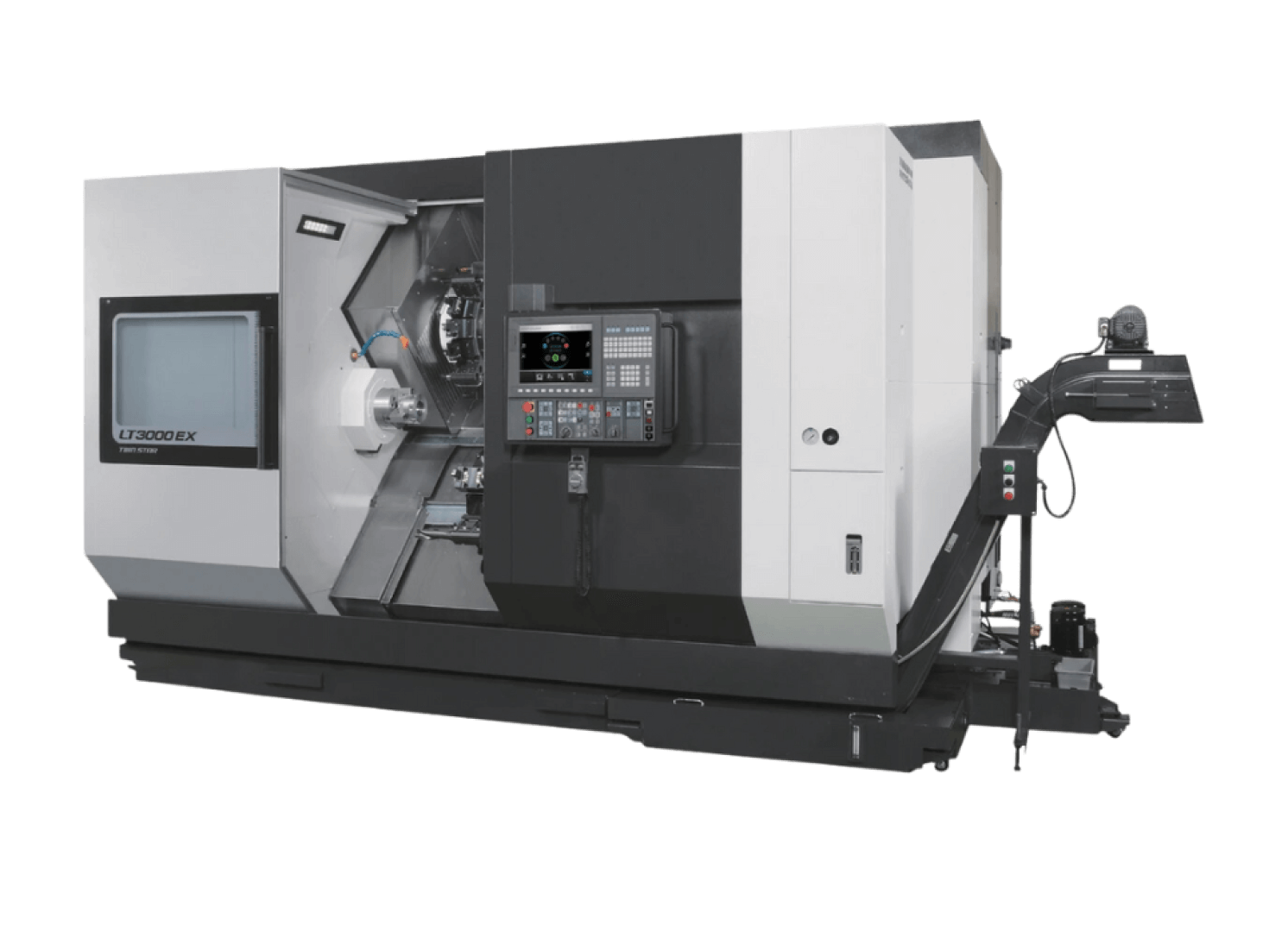

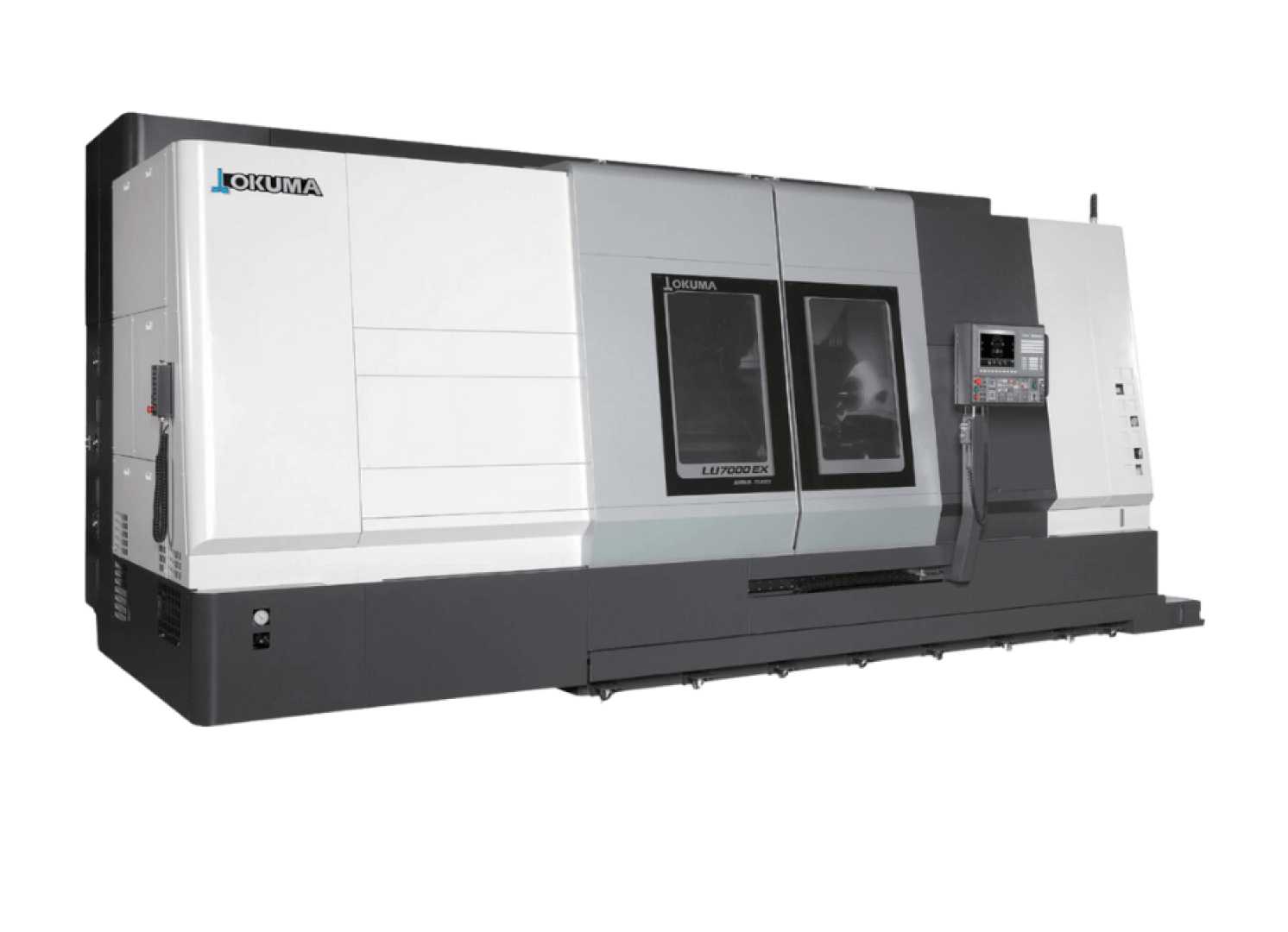

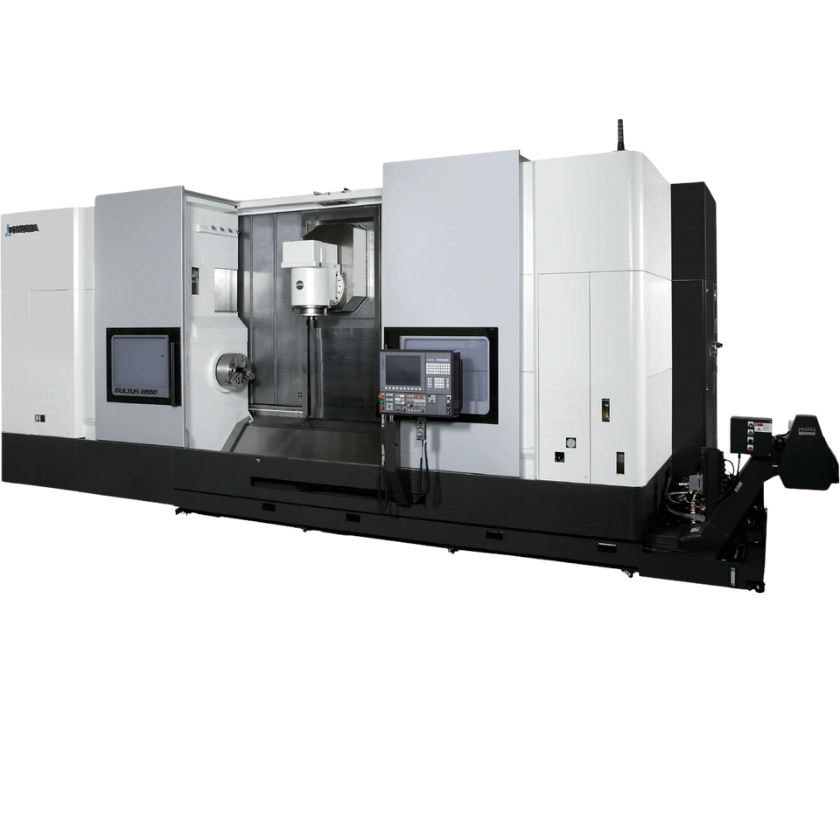

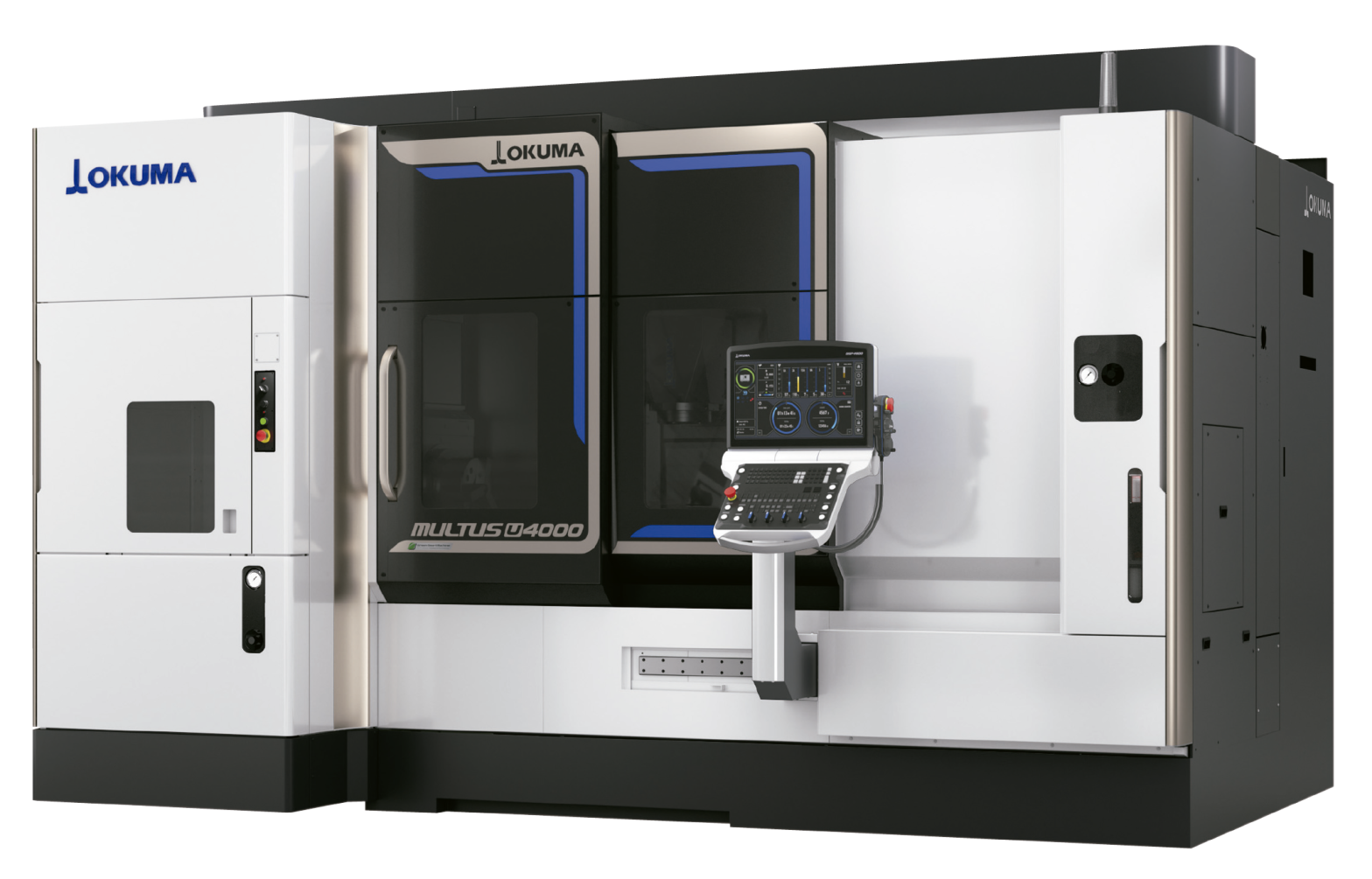

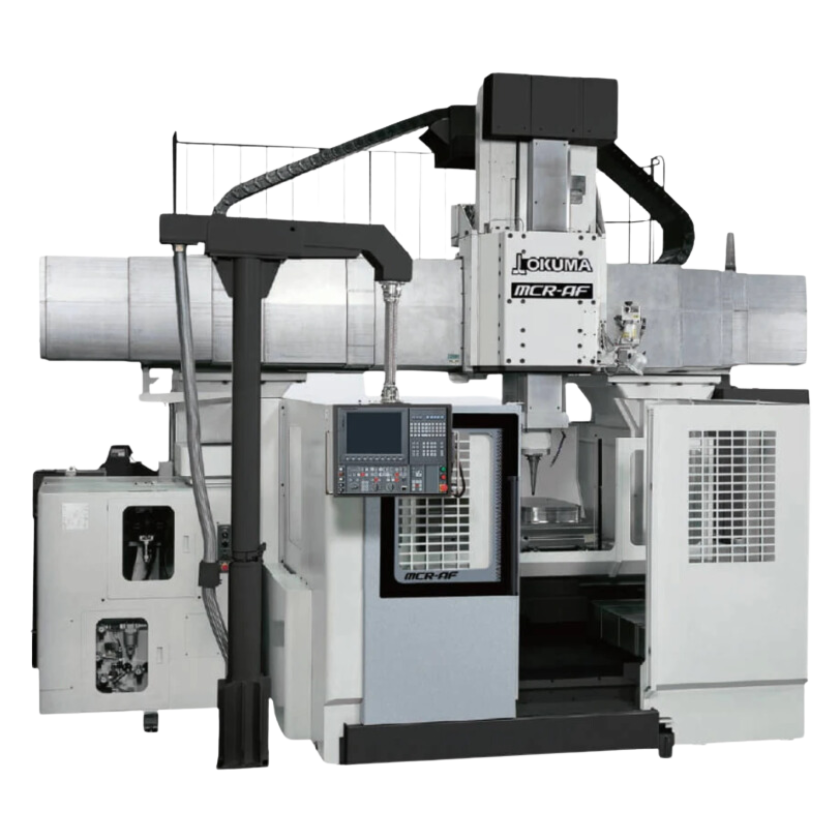

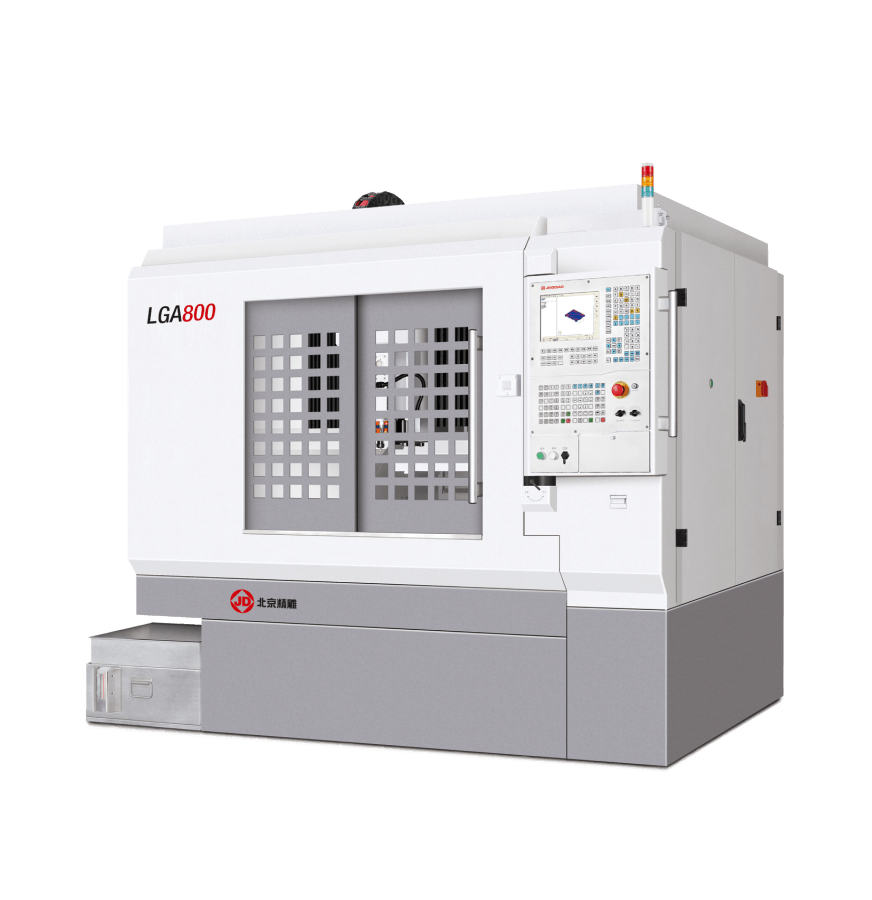

Combinaciones frecuentes para mejorar tus procesos en Tornos CNC, Centros de Maquinado CNC y demás Equipo para Mecanizado.

Equipe y maximice la productividad de sus Máquinas CNC con soluciones integrales

Creación y desarrollo de automatización industrial a la medida de sus necesidades