MODIG

MODIG

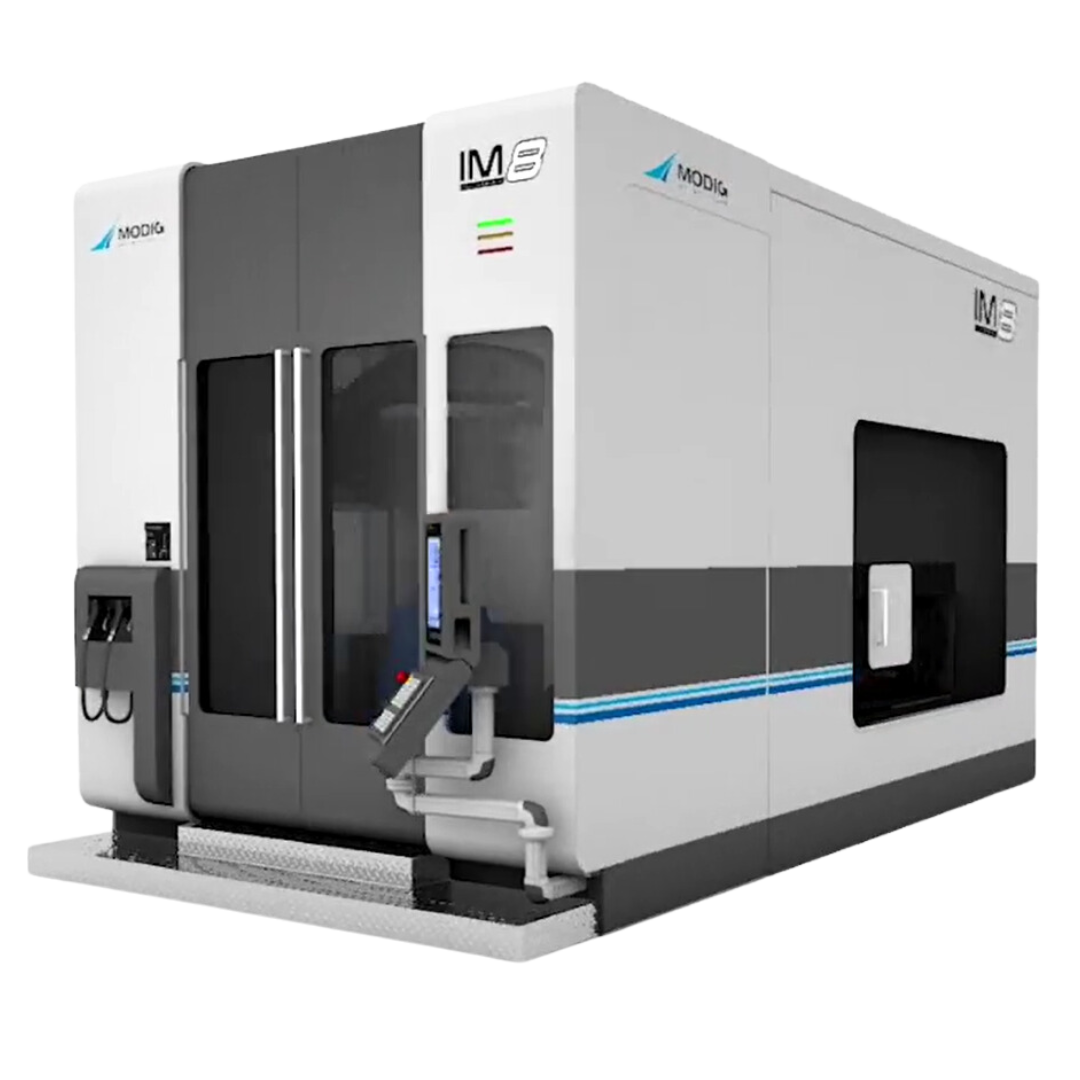

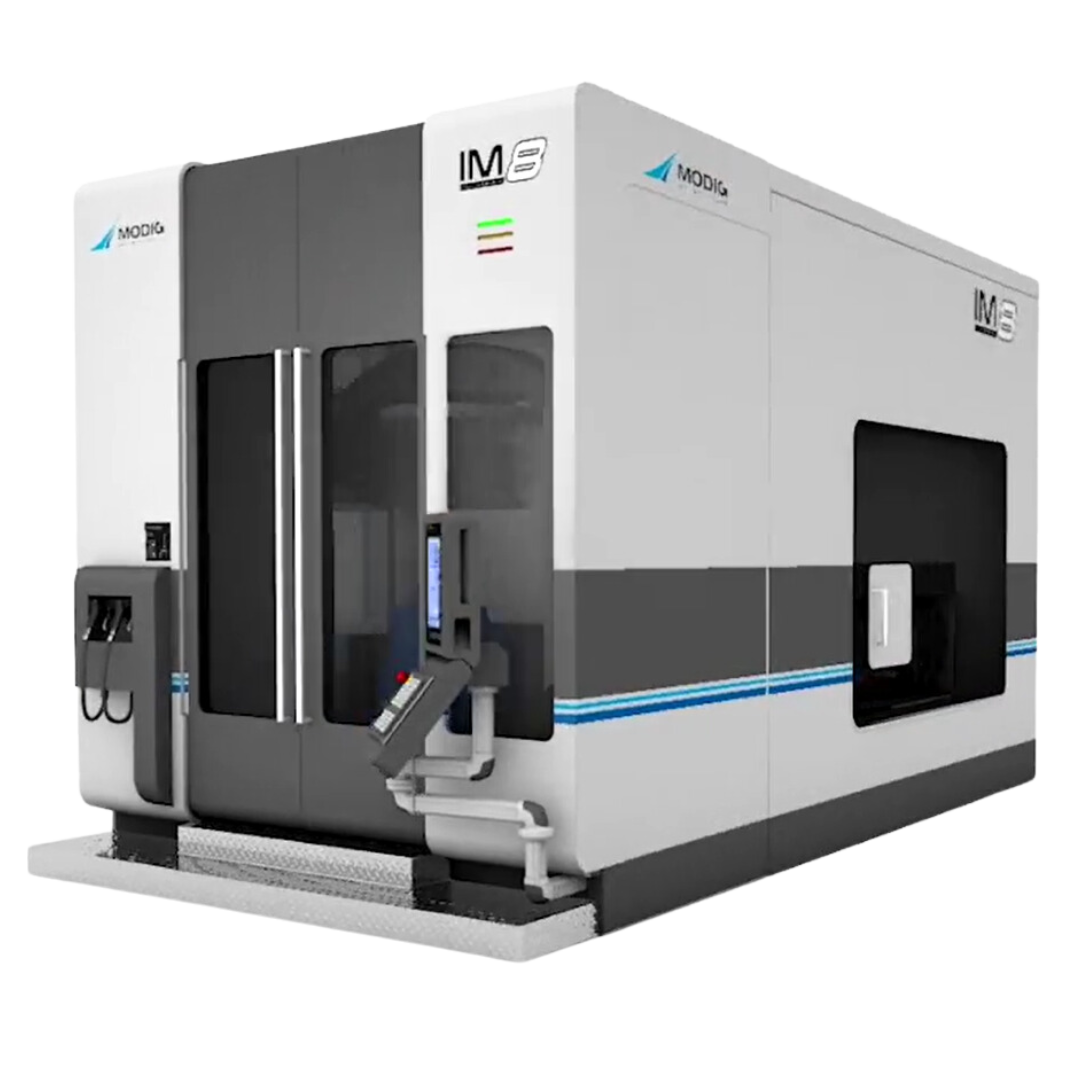

IM8

Product description

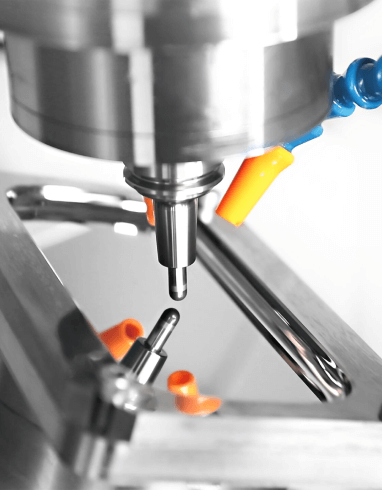

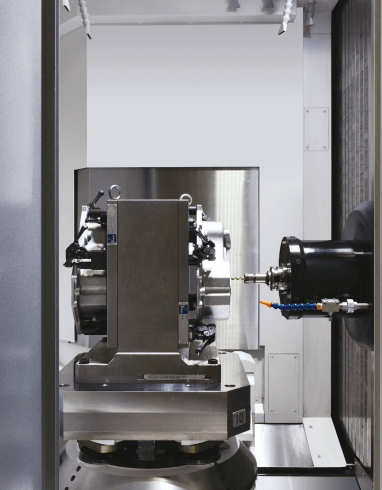

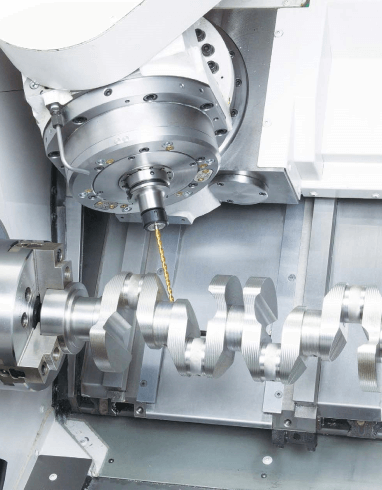

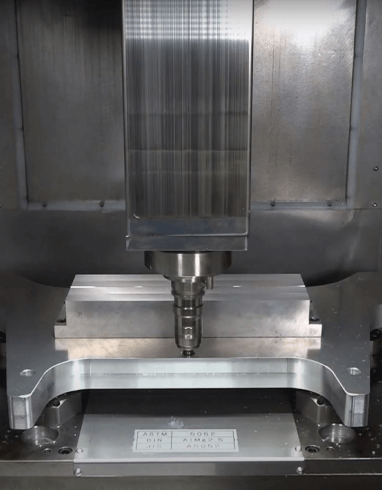

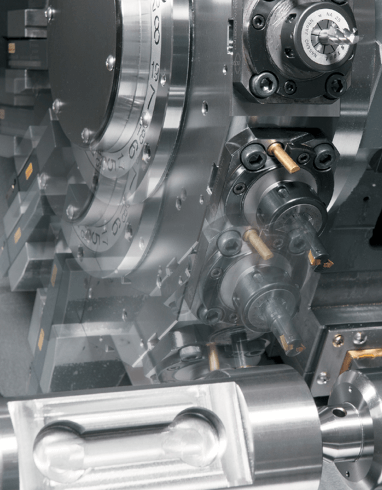

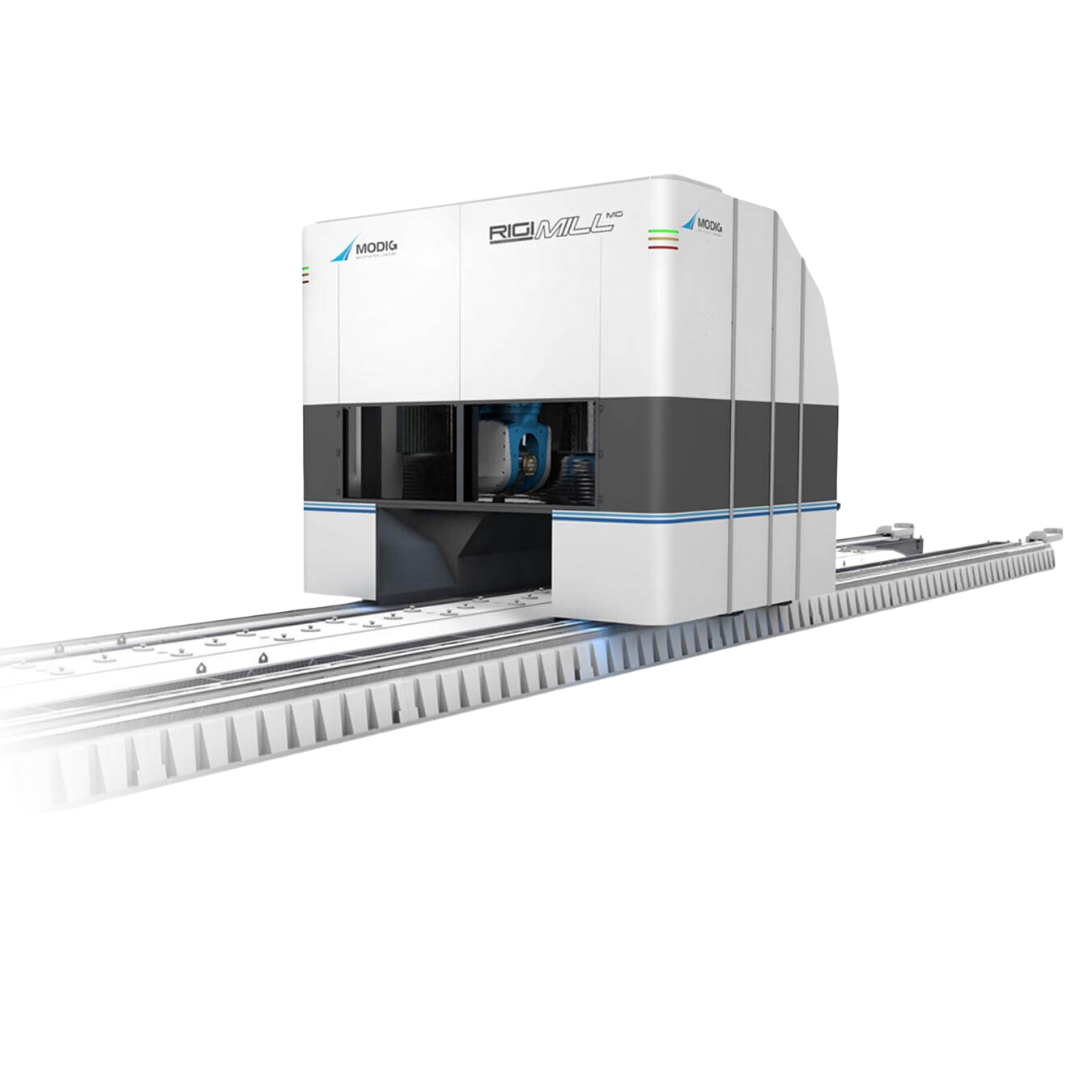

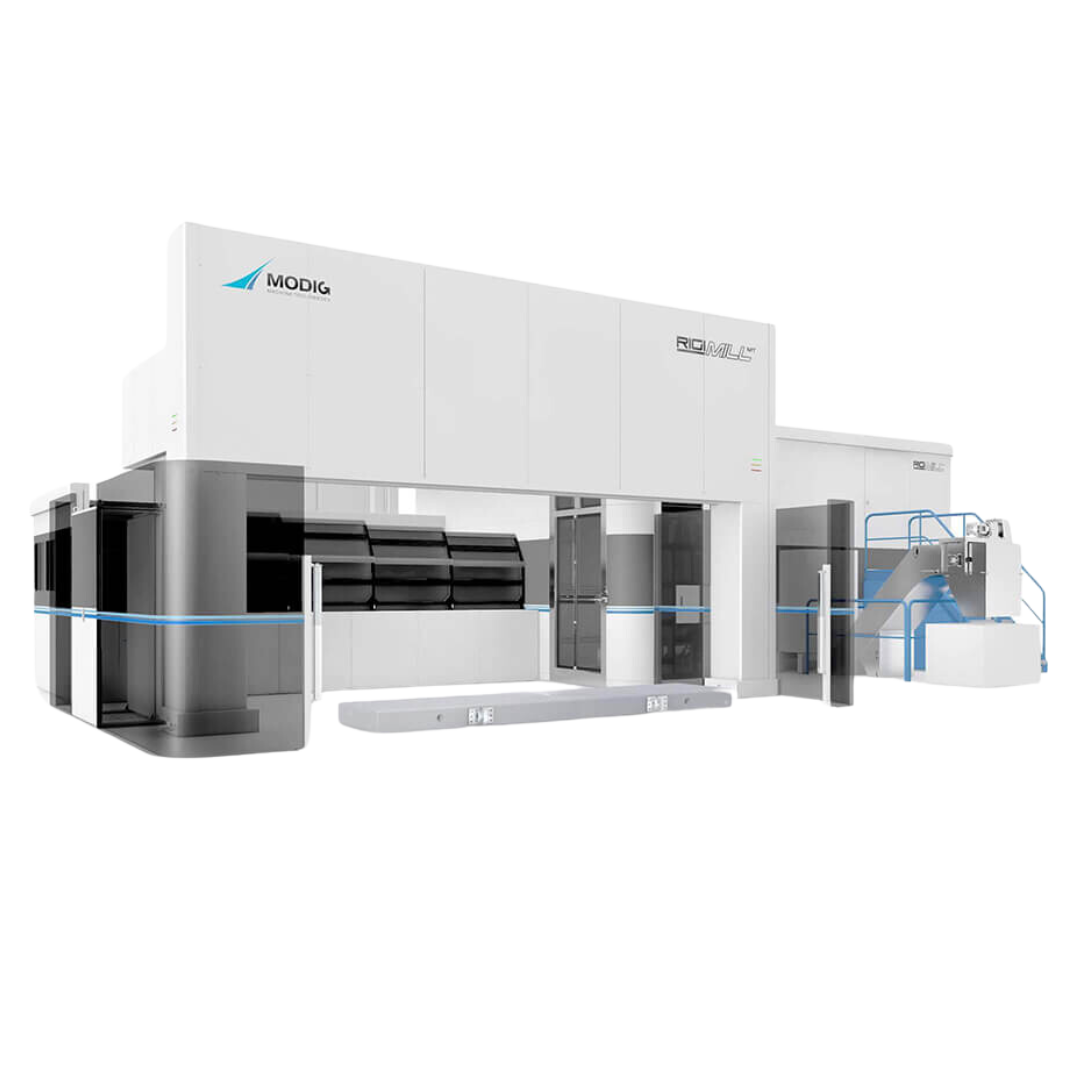

The IM-machine series was born to meet today’s manufacturing signified by ever more closely geometric part tolerances, part and component complexity, and faster production times within the industry. The machines processing from below transforms the way we will think about generic 5-axis and component machining. So, let us think inverted.

With a patented design, a single spindle with up to 200 hp (150 kW) working from below, this high-speed inverted machining center sets a new standard for 5-axis machining. The machine is suitable for industries characterized by large volumes, quick lead times, and high complexity.

Industries

Aerospace

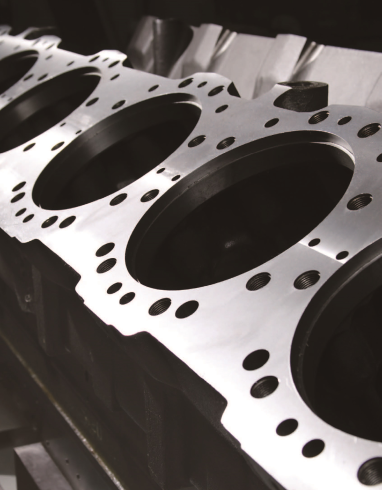

Automotive

Heavy Duty

Others

Key product information

Trunnion table (in)Trunnion table (mm)

31800

Maximum part size (in)/ diameter (in)Maximum part size (mm)/ diameter (mm)

39 x 26 x35 / 471000 x 660 x 900 / 1200

Travels (X / Y / Z / C / A) [in]Travels (X / Y / Z / C / A) [mm]

39 / 39 / 31 / 300° / 360°1000 / 1000/ 800 / (±120° + 60°) /continuos

Maximum part height (in)Maximum part height (mm)

28700

Inference of the maximum size of the piece ø diameter (in)Inference of the maximum size of the piece ø diameter (mm)

391000

Standard spindle (Velocidad) [rpm]

30,000

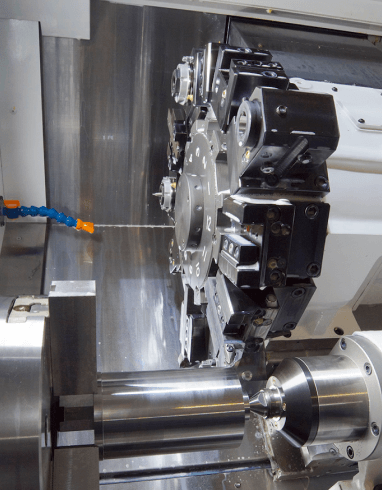

Number of tools (standard)

60 / 120

Tool Taper

HSK-63A

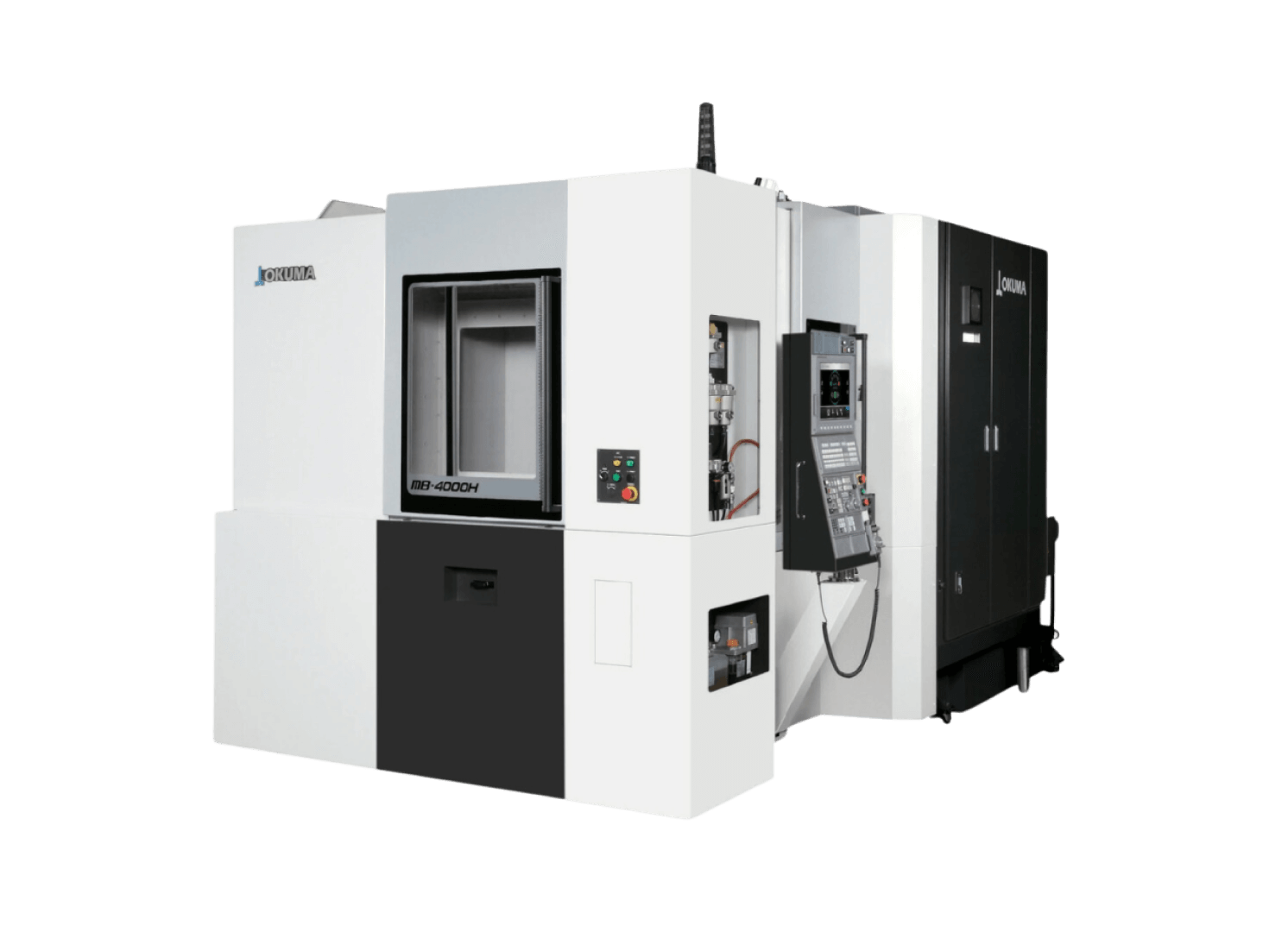

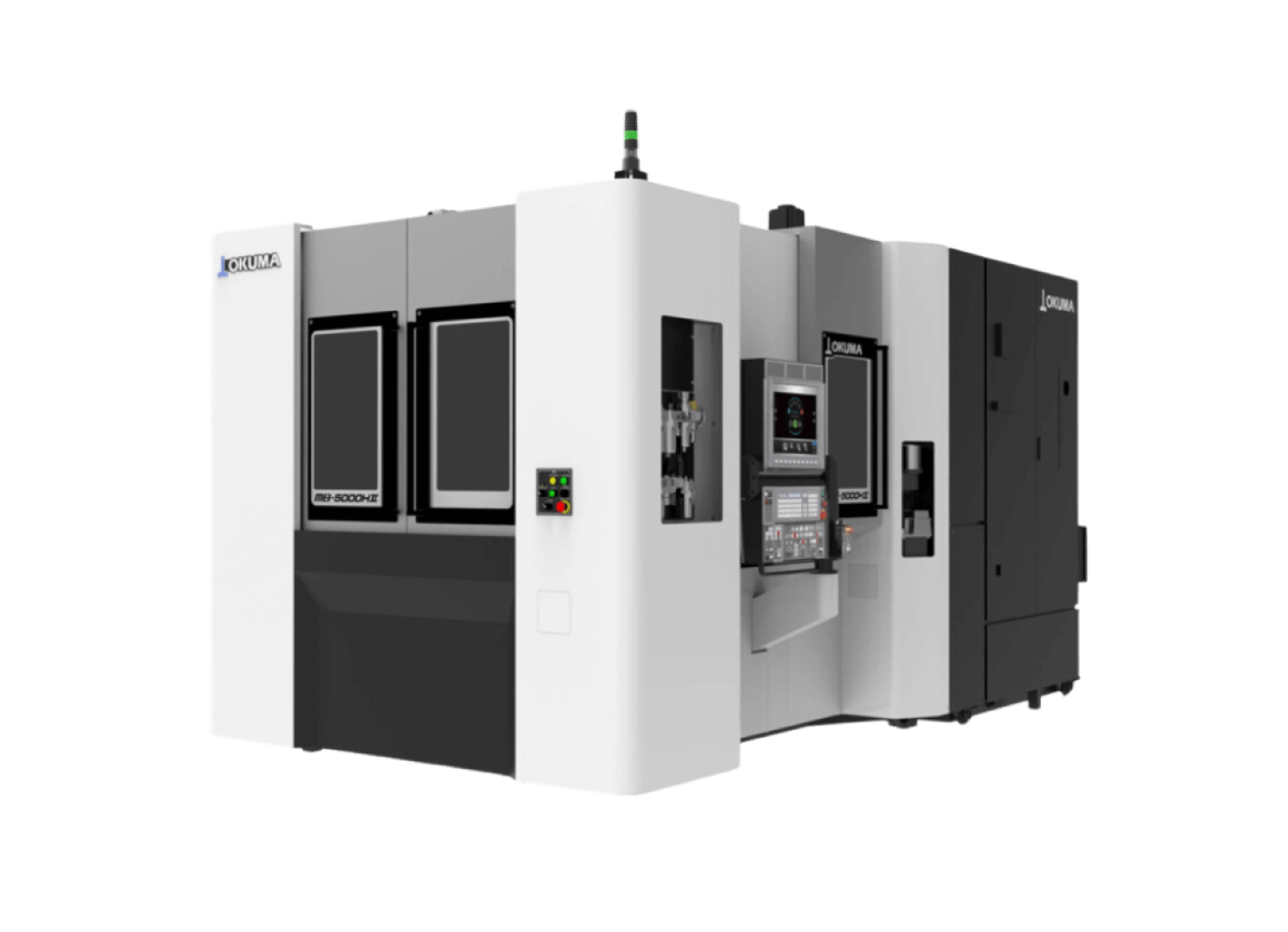

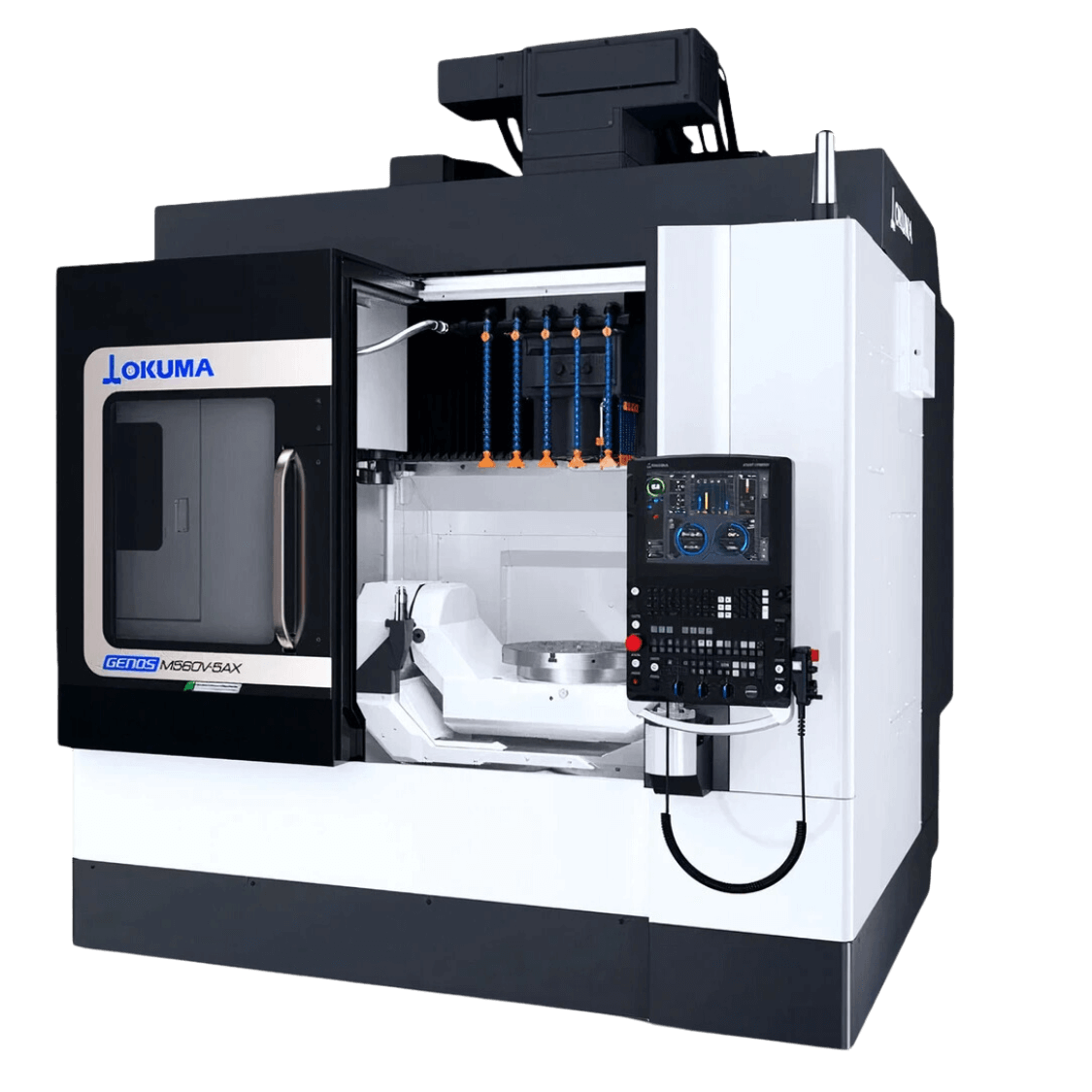

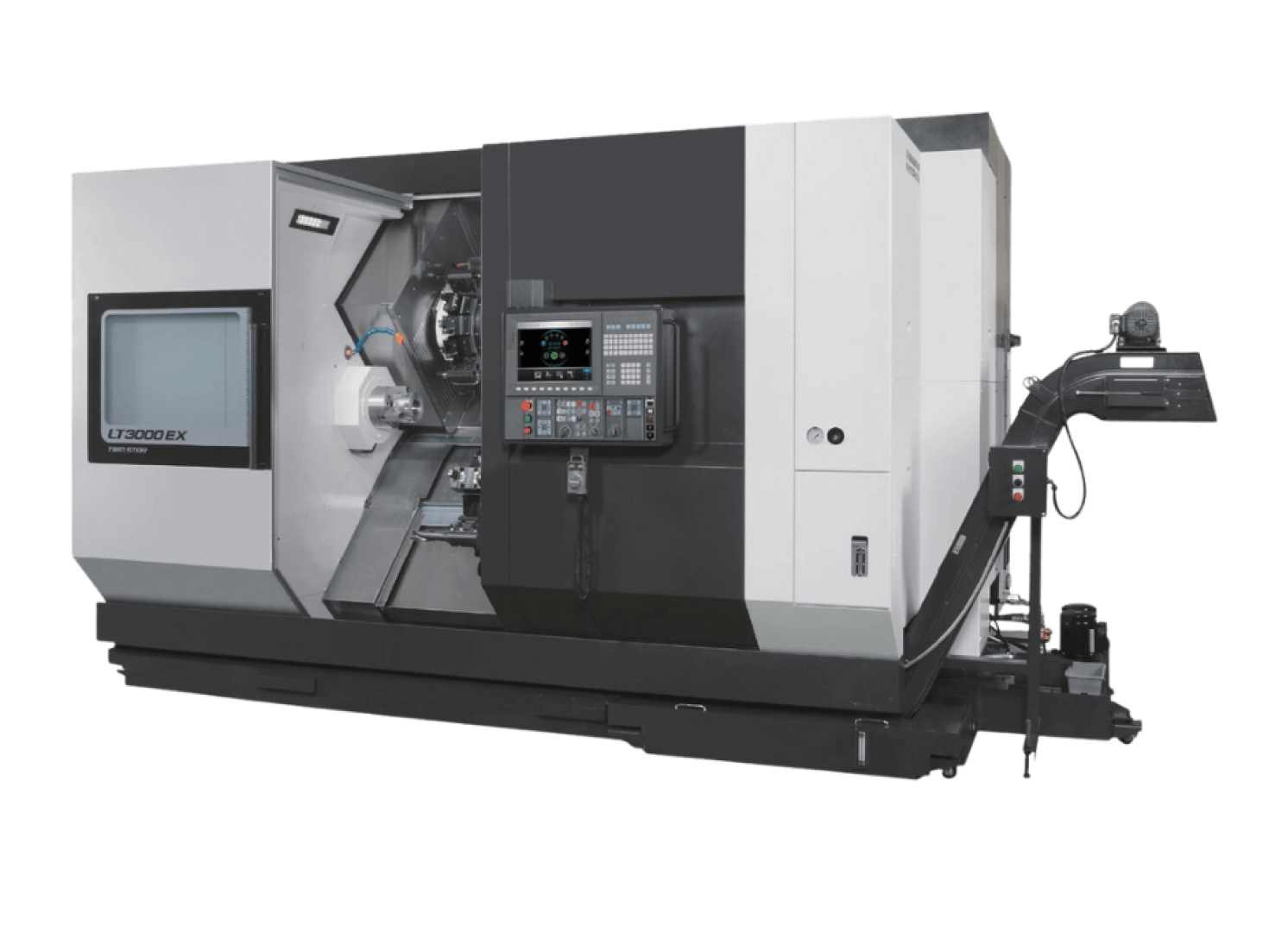

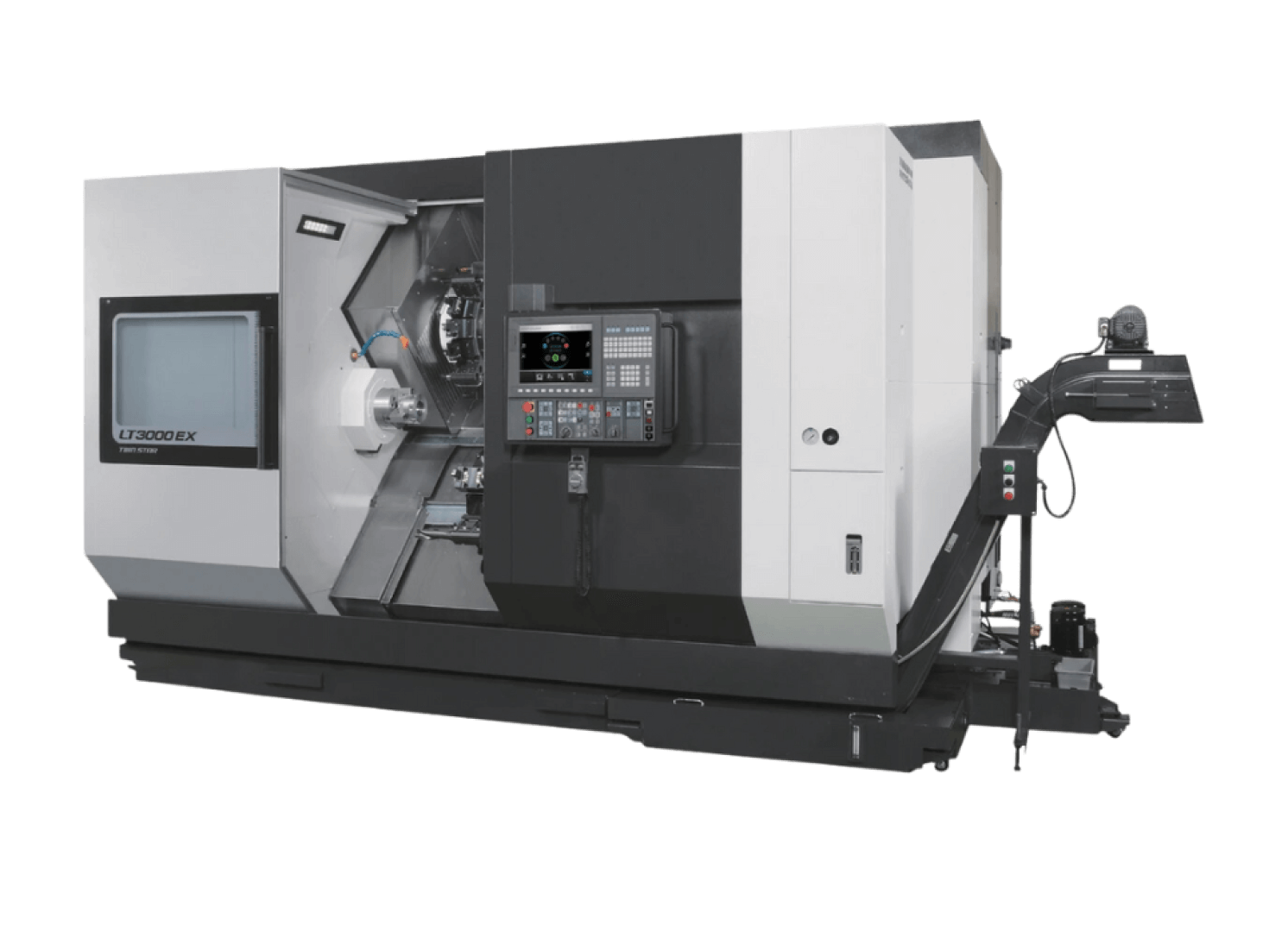

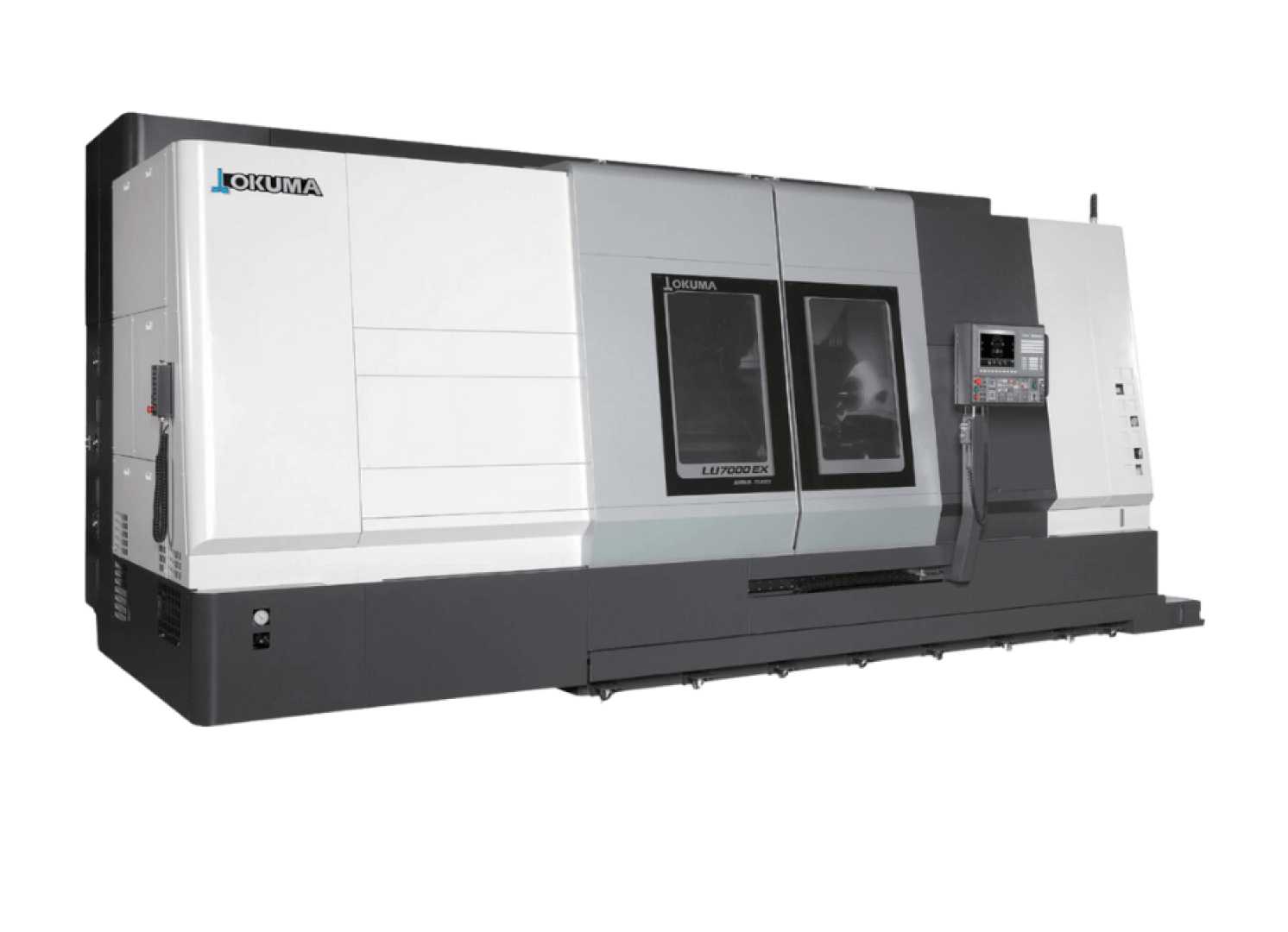

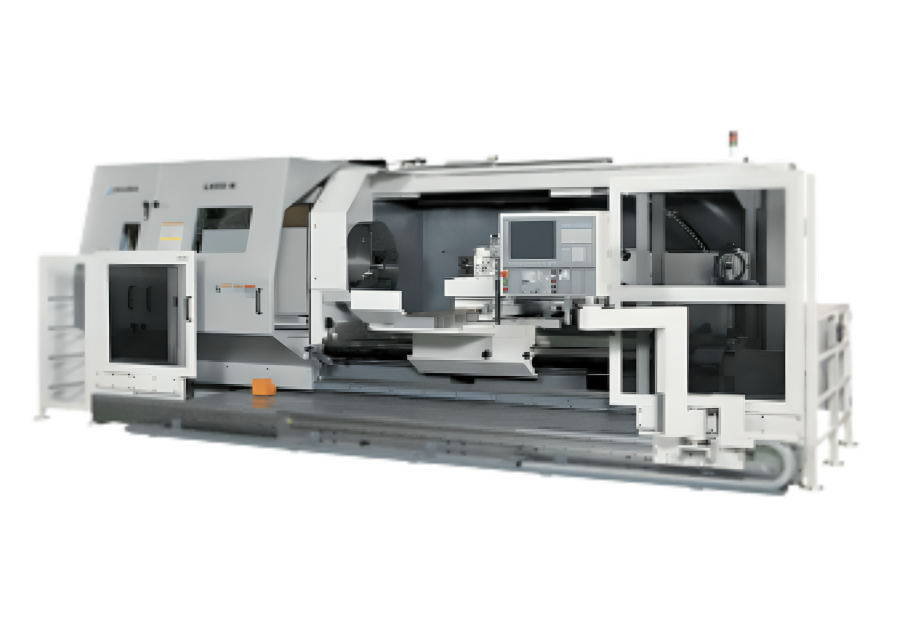

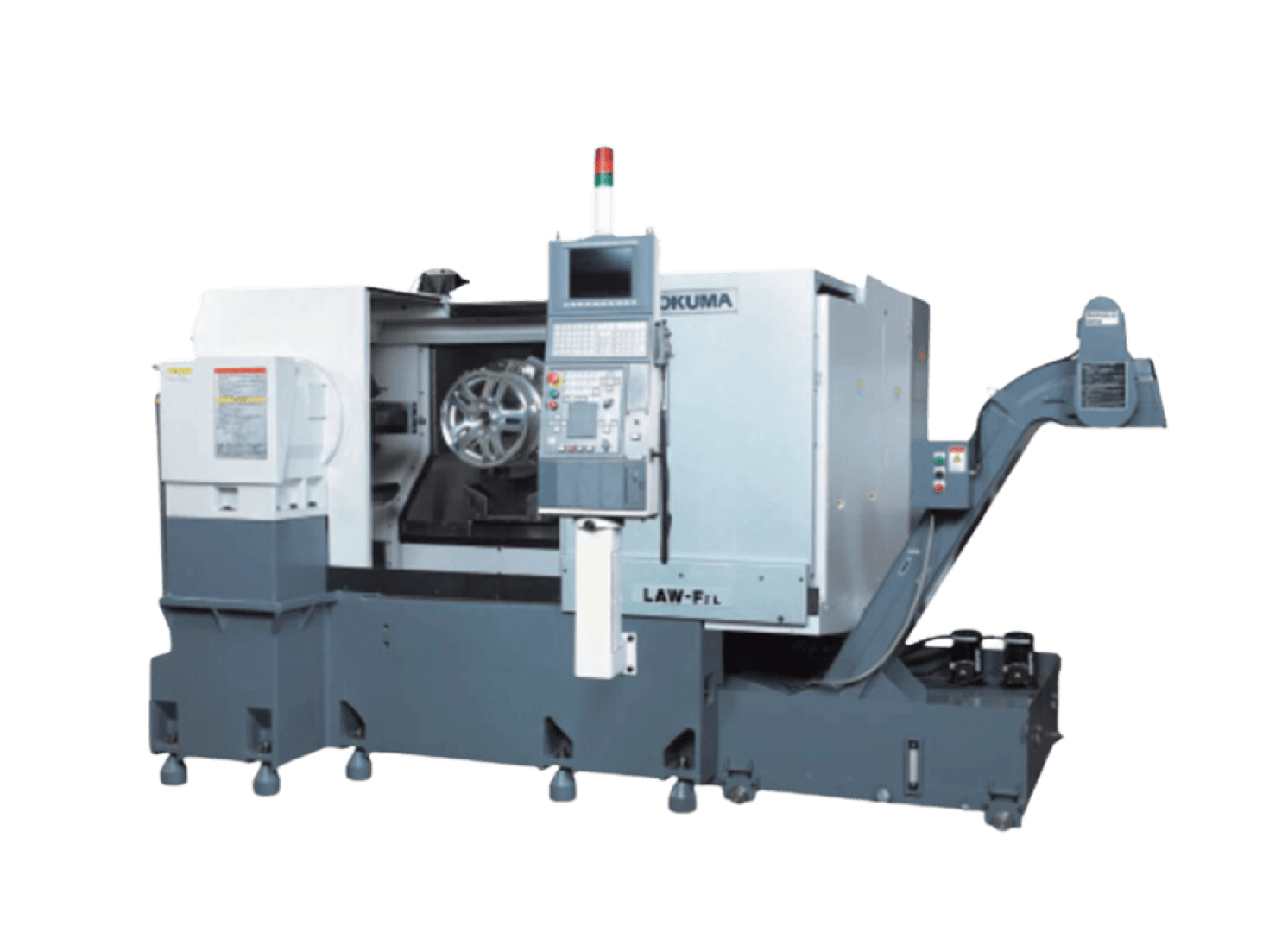

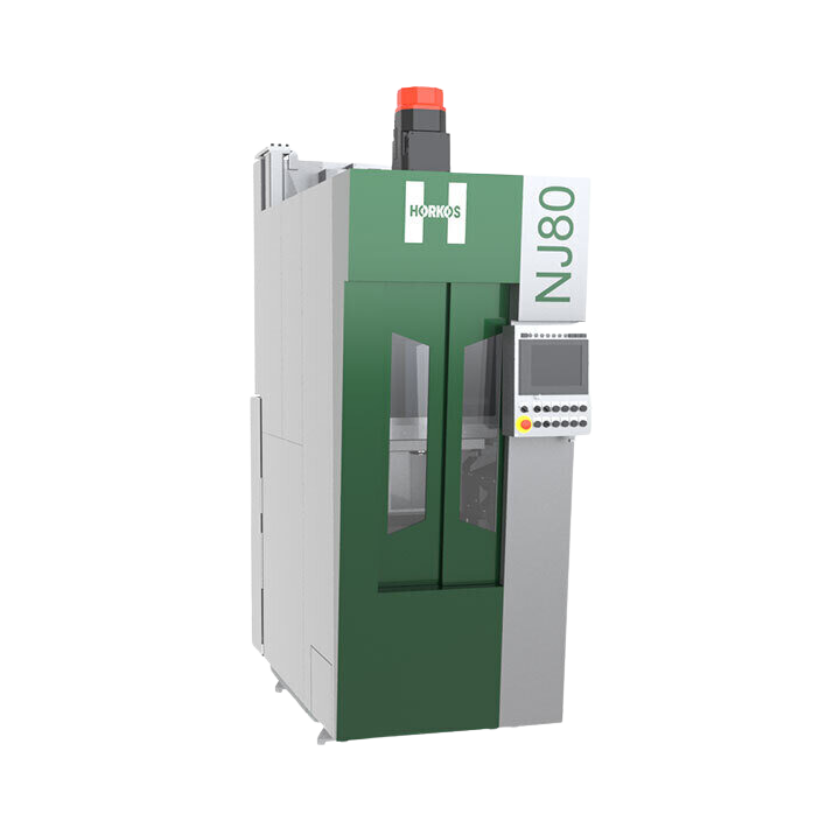

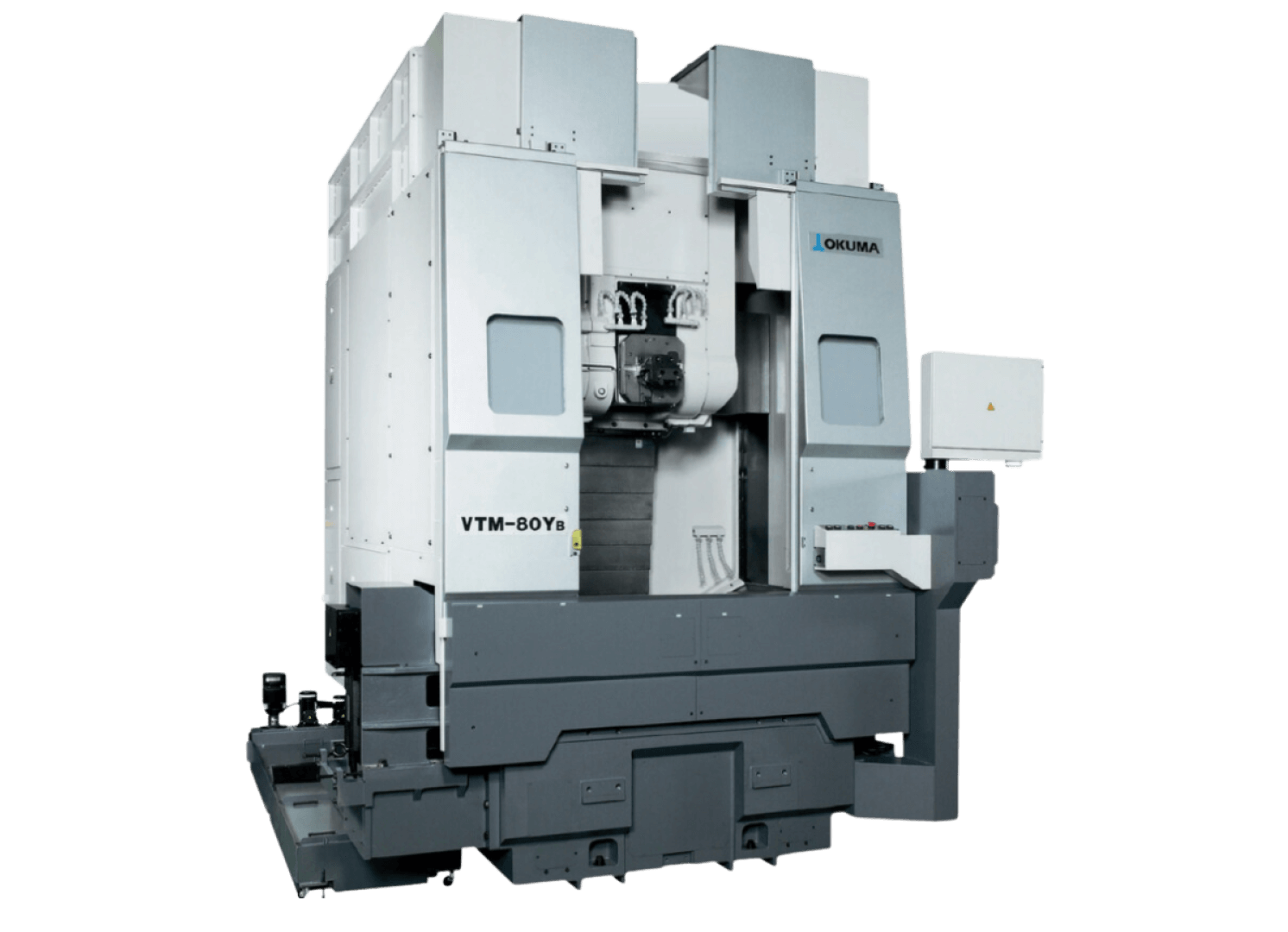

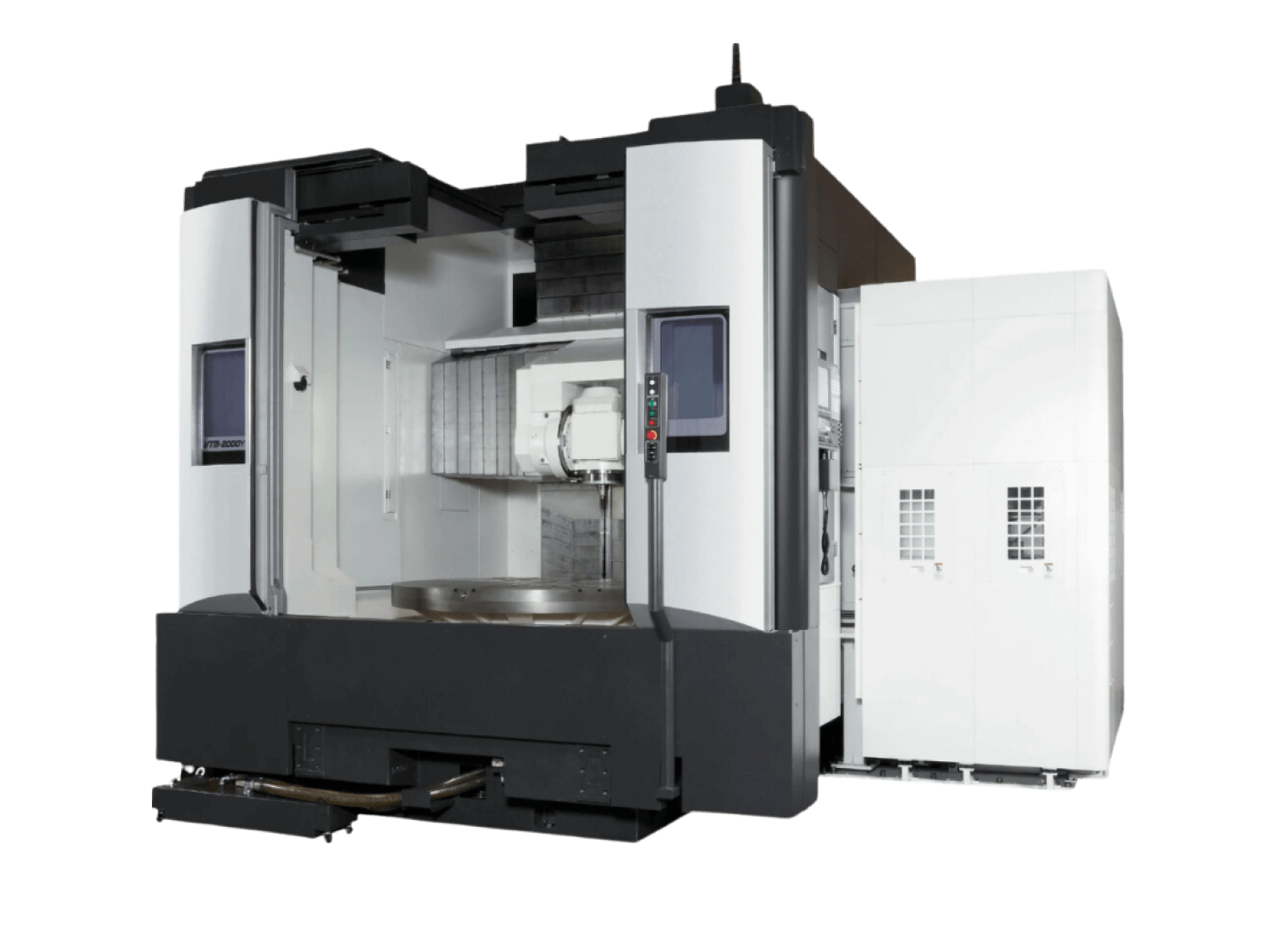

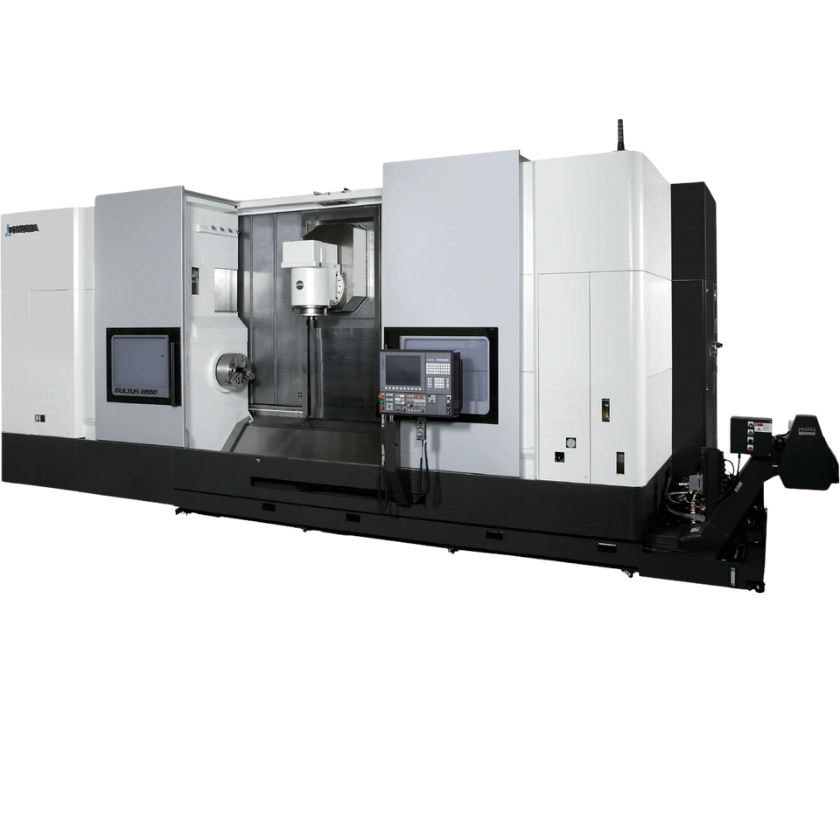

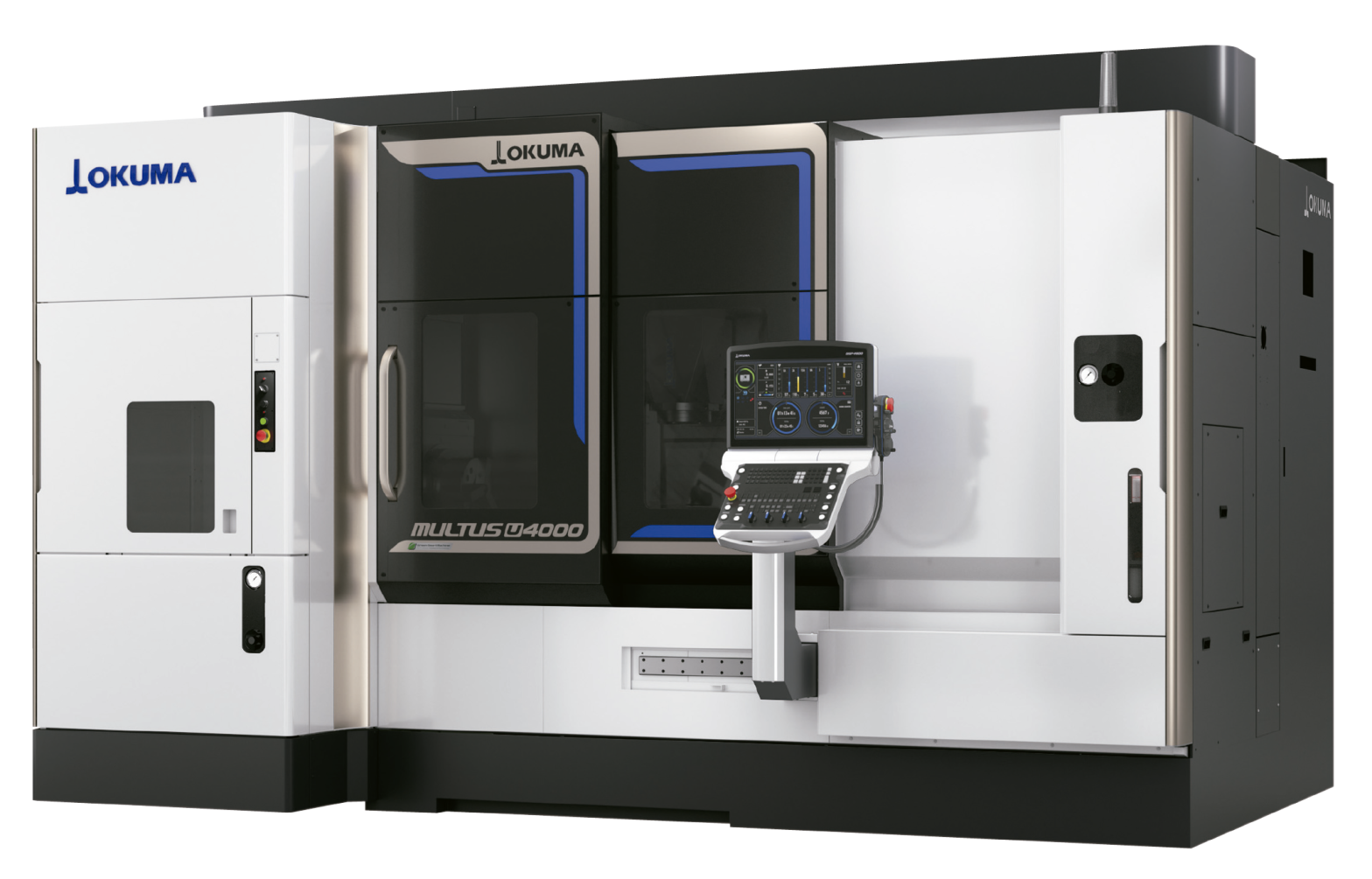

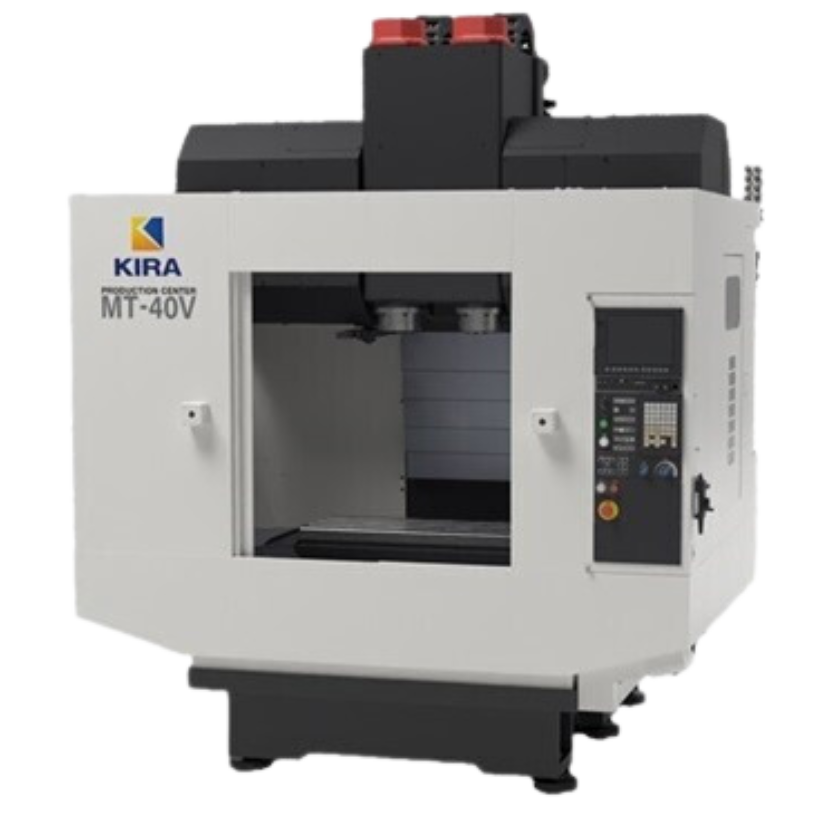

Combinaciones frecuentes para mejorar tus procesos en Tornos CNC, Centros de Maquinado CNC y demás Equipo para Mecanizado.

Equipe y maximice la productividad de sus Máquinas CNC con soluciones integrales

Creación y desarrollo de automatización industrial a la medida de sus necesidades