MODIG

MODIG

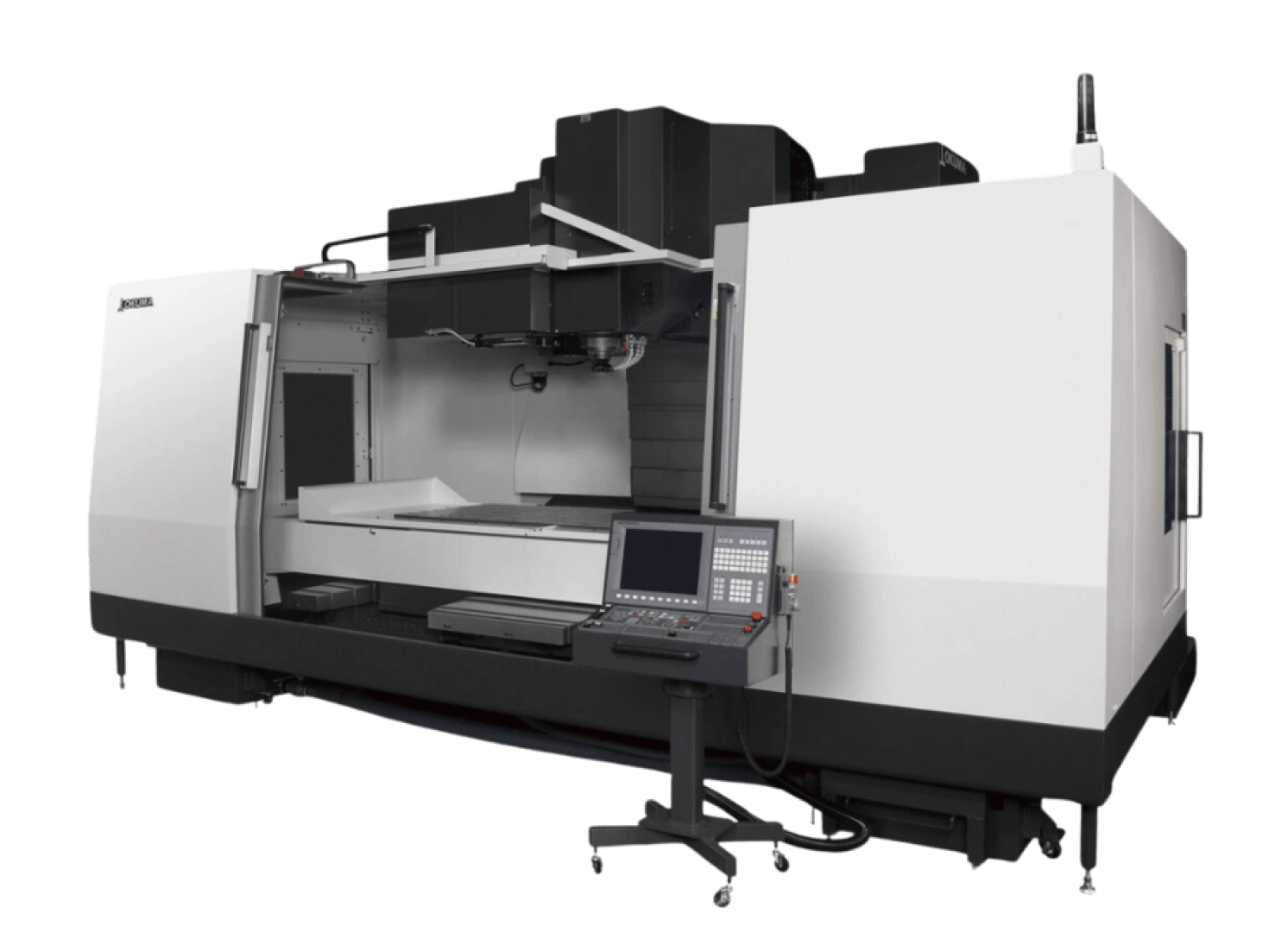

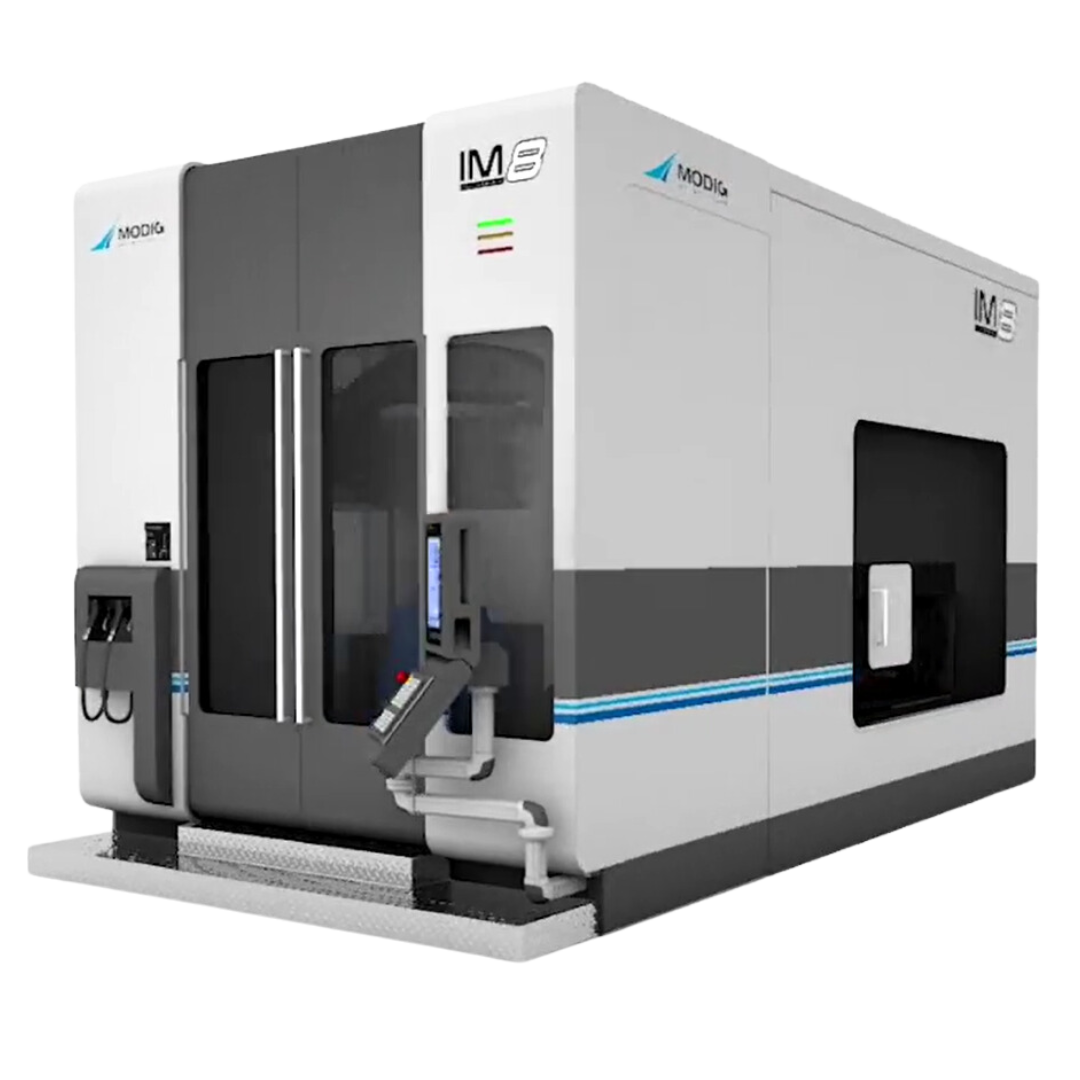

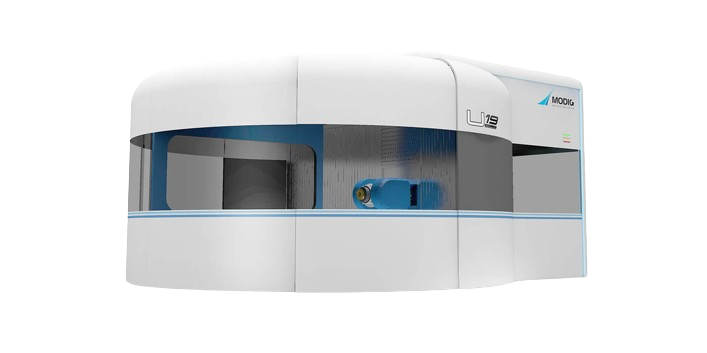

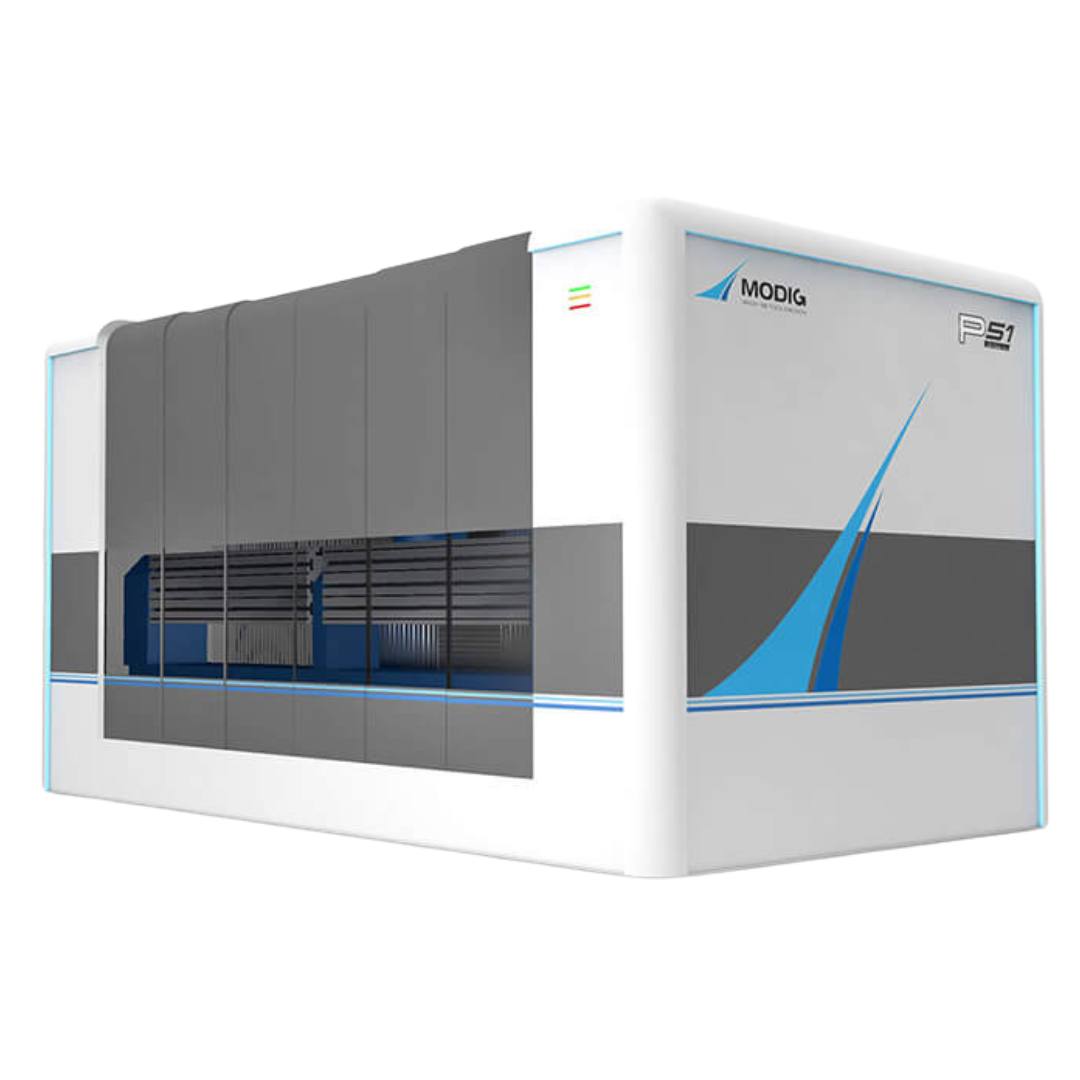

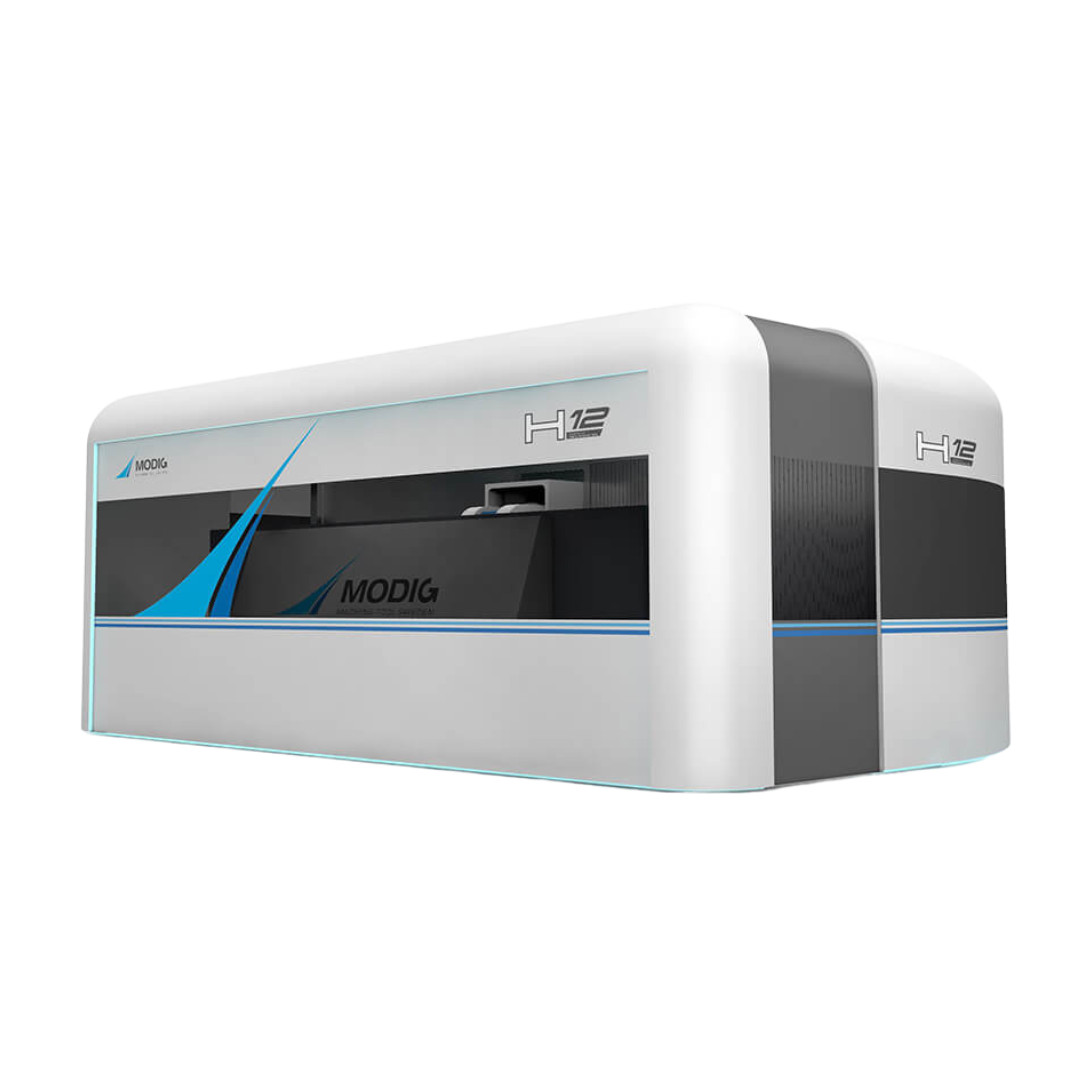

Mill-Ex

Product description

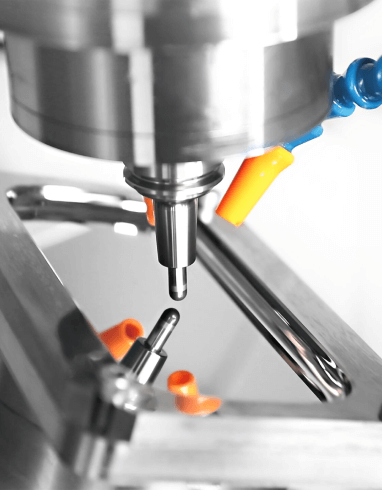

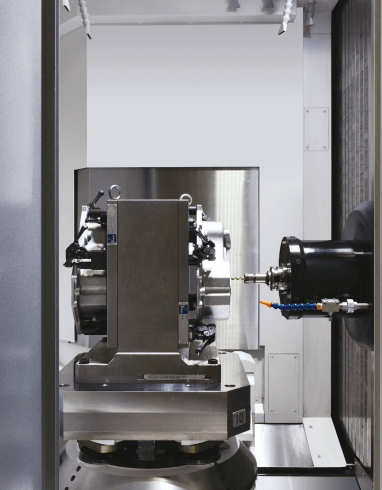

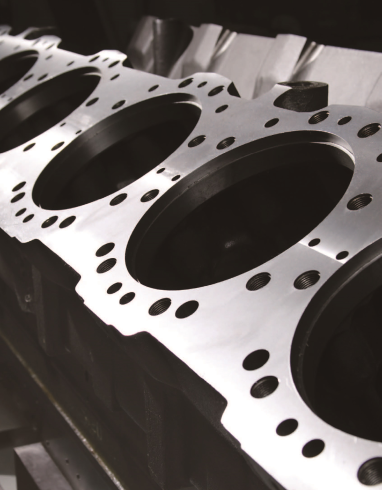

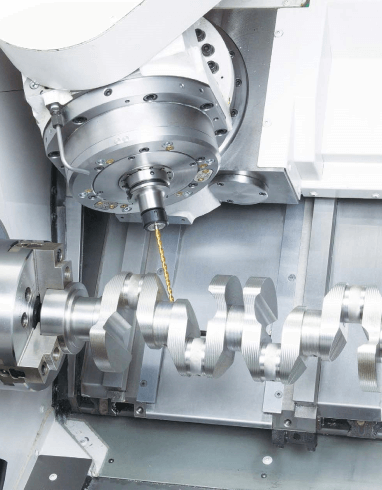

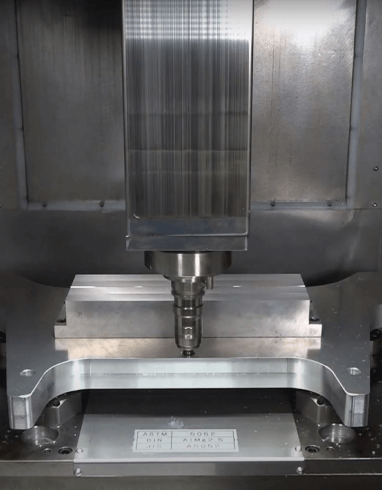

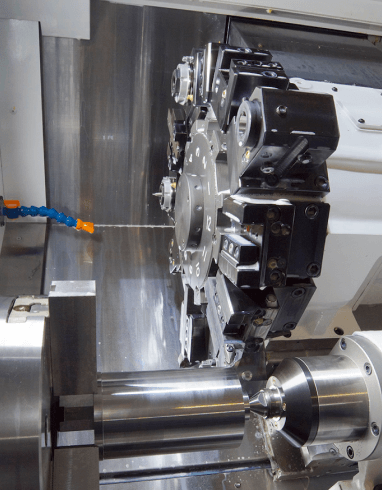

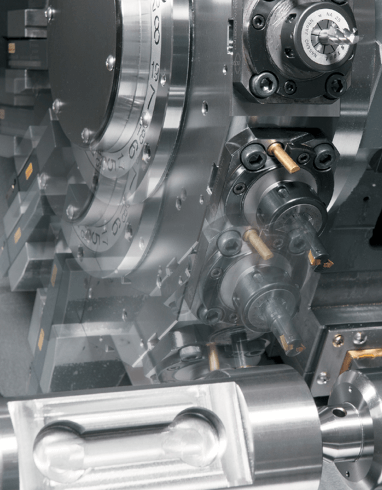

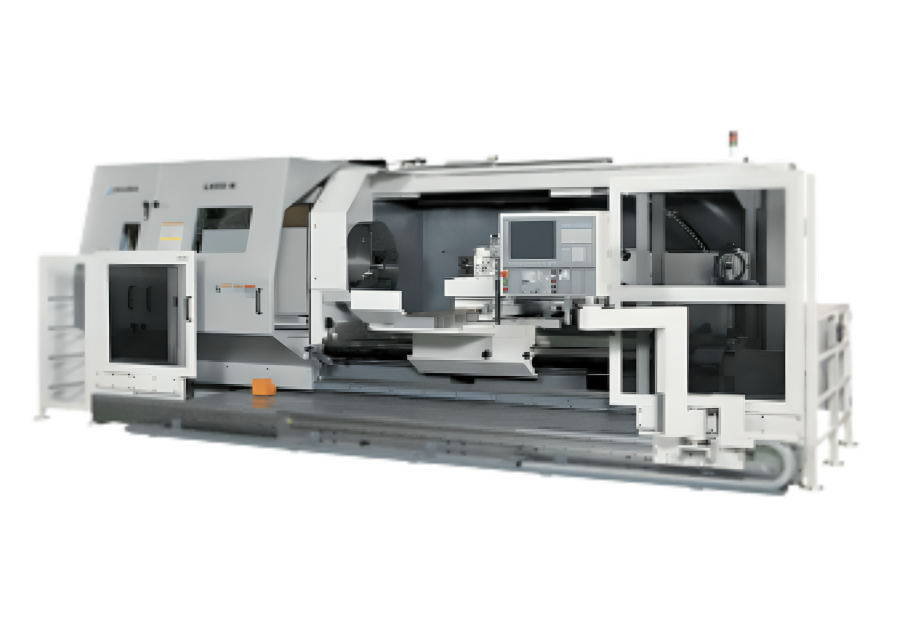

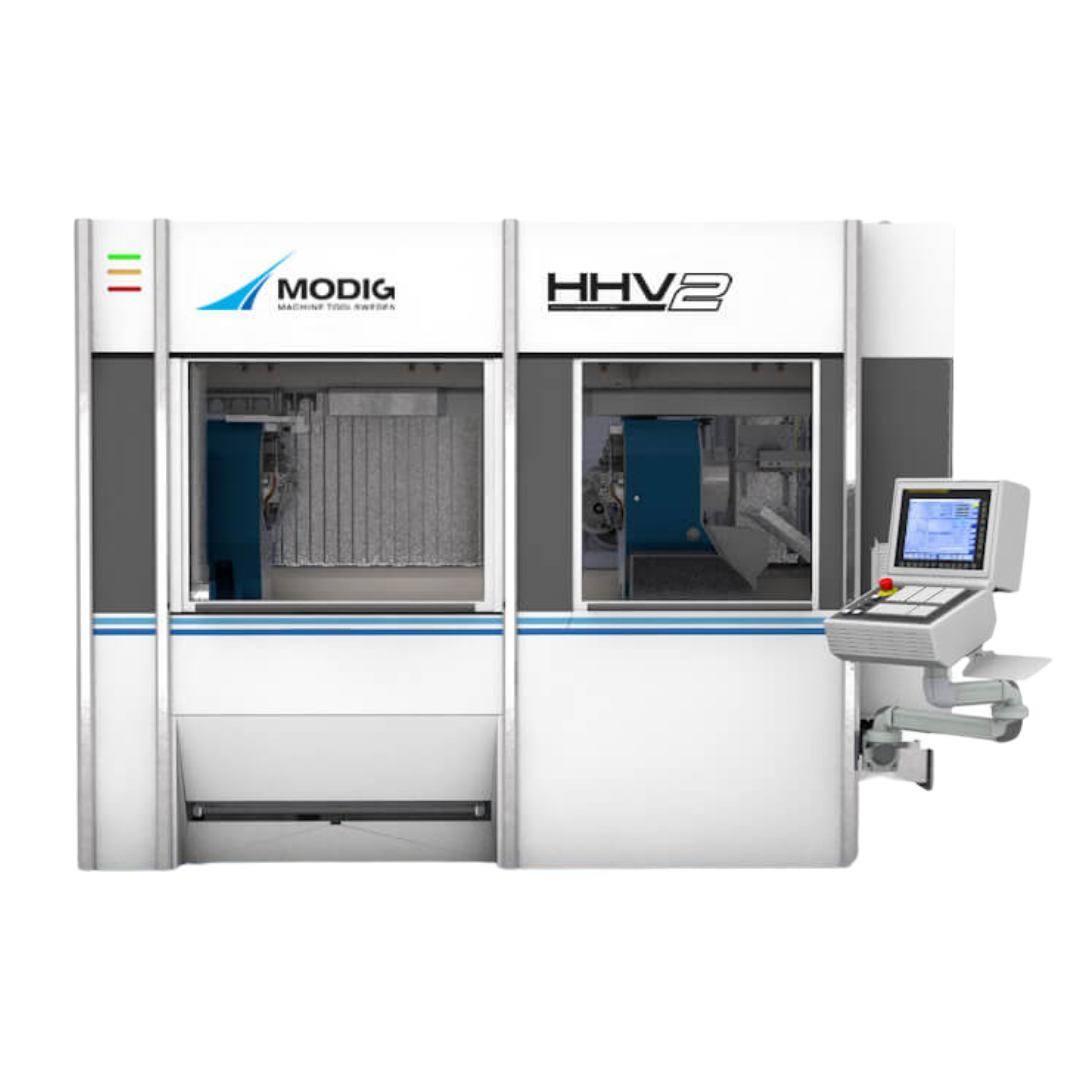

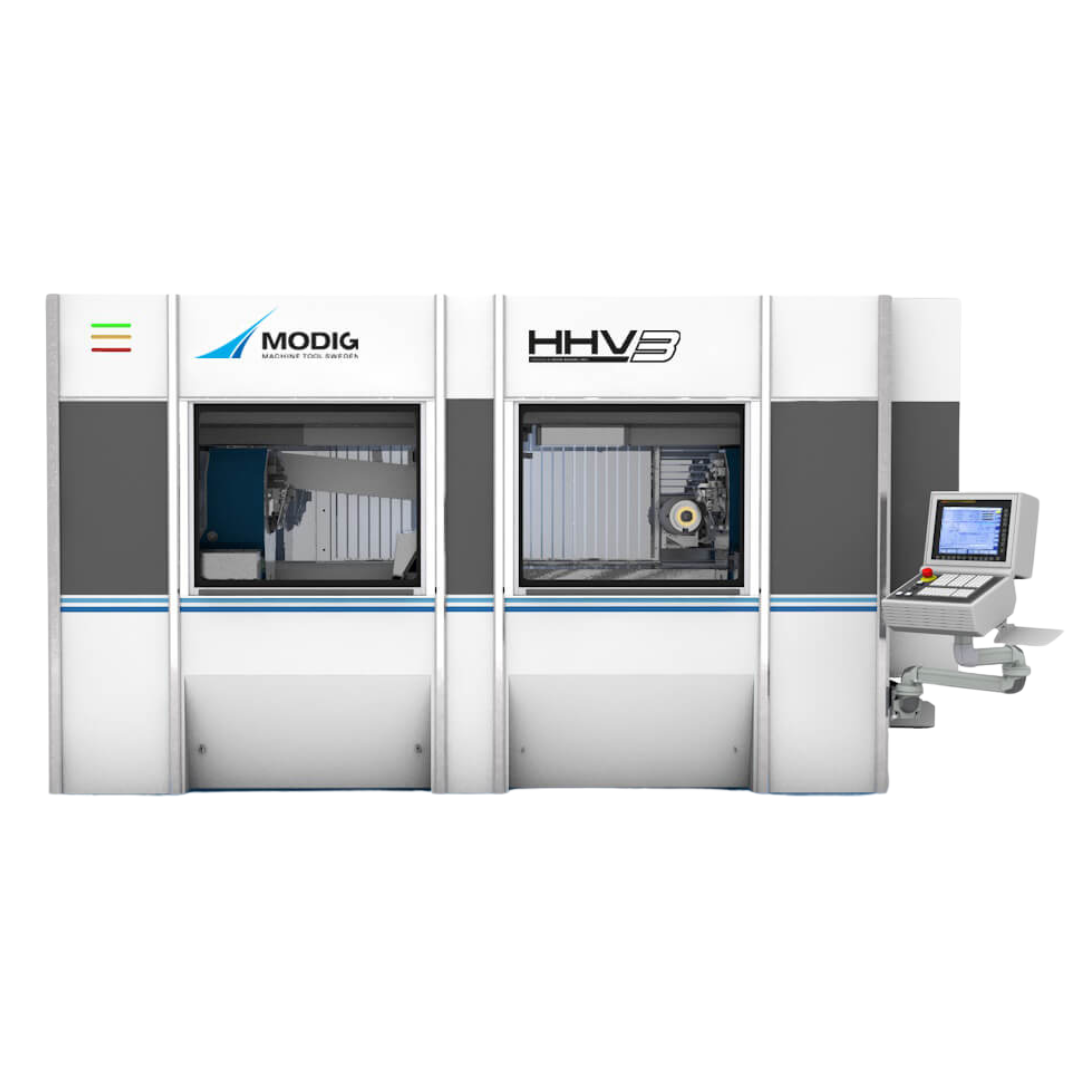

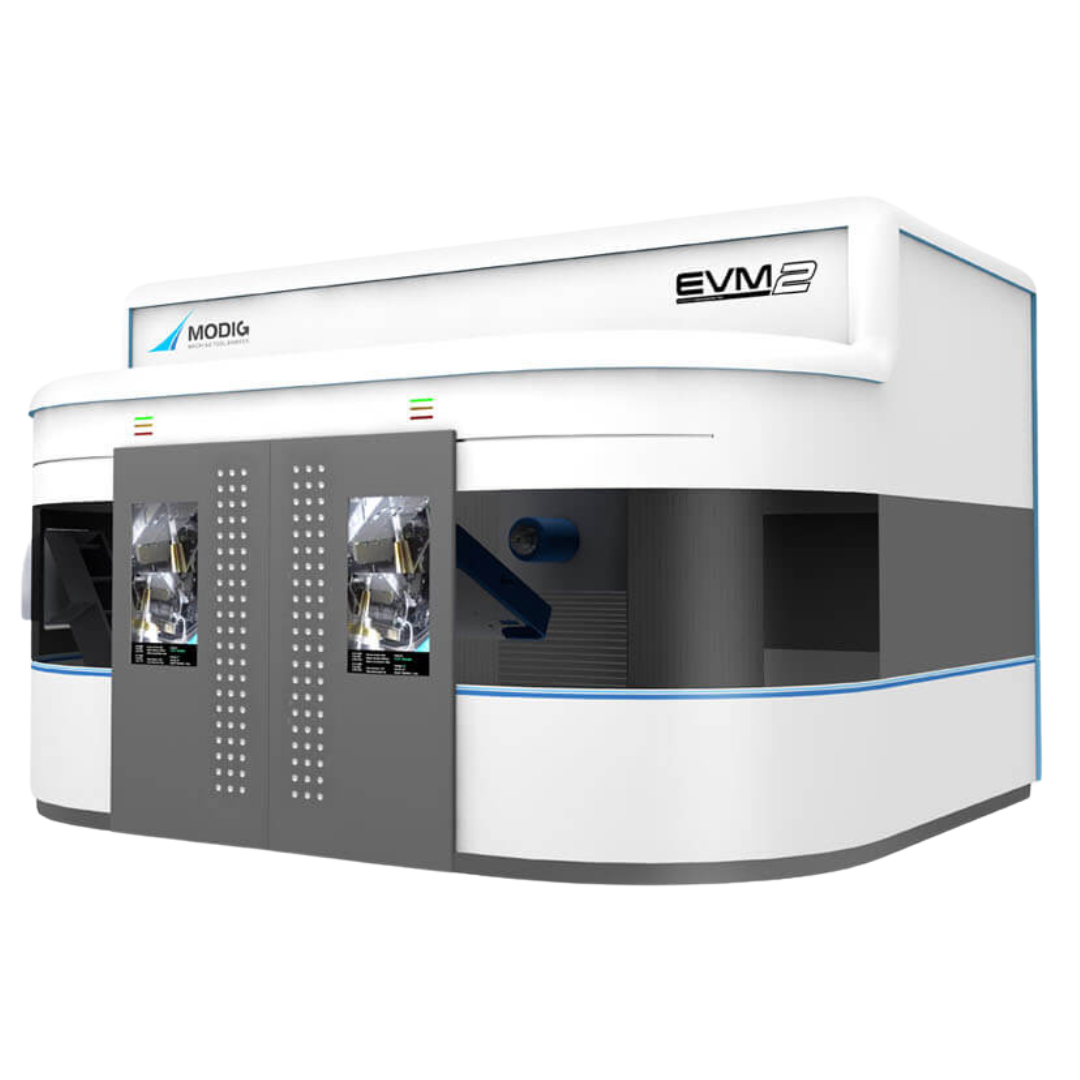

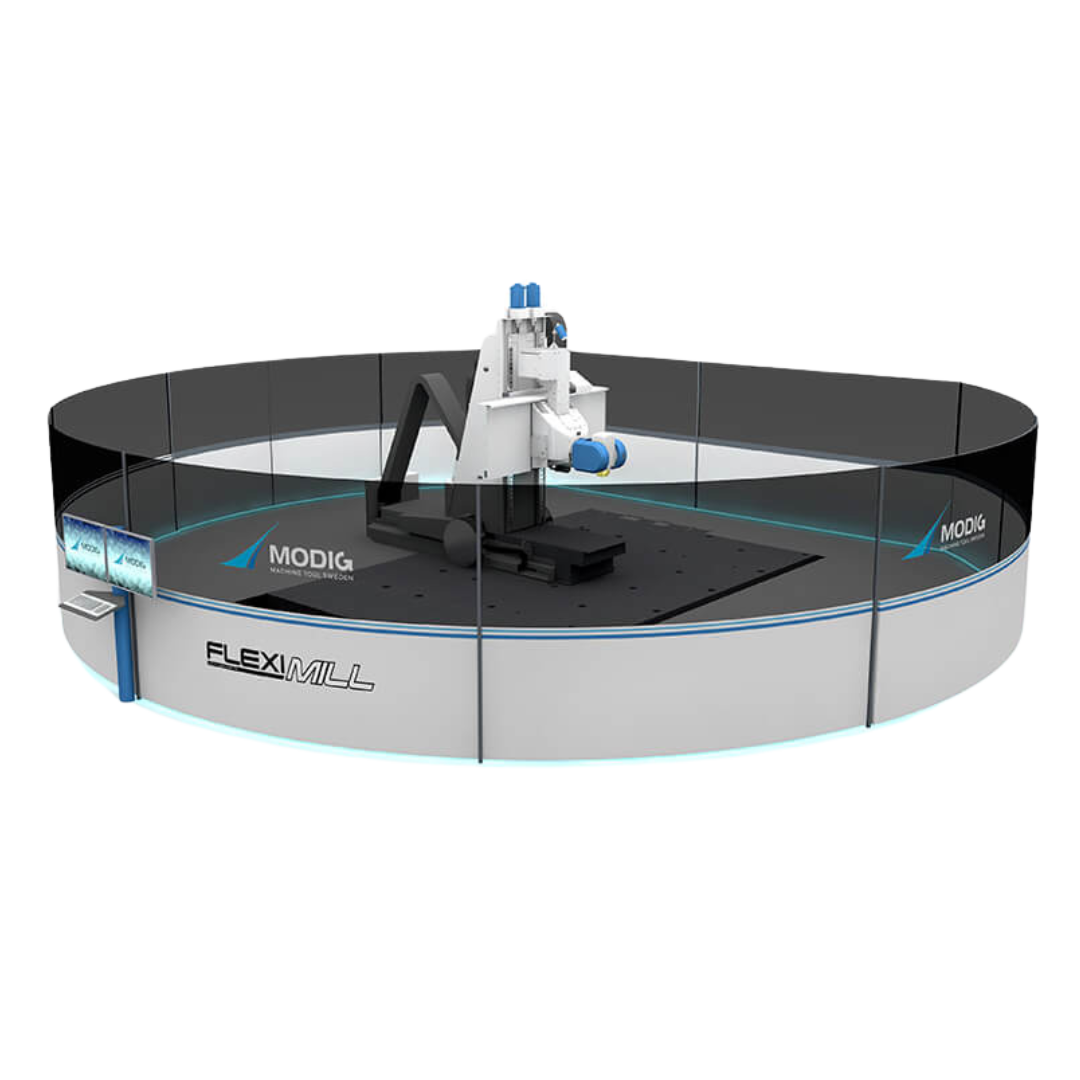

Mill-Ex is a high-speed milling machine with 2 or 4 spindles individually driven in all three axes. With up to 1.5G acceleration and high feed rates, it is well suited for the demands of aluminum machining. A key benefit is machining parts in one setup with a 2 or 4 spindles – higher part throughput with lowest cost per part. Typical parts are aluminum components for automotive (cross member, battery tray, body-in-white) aerospace (floor beam, wing rib, airframe), electronics, and many other applications. The Mill-Ex manufacturing solution offers the opportunity to customize the solution with for example different coolant options (high-pressure coolant, MQL, or dry milling) and loading/unloading (manual or automated by overhead gantry robot or by 6-axis robots from the front). The 2 spindles configuration provides the ability of loading new raw material while machining. The low cost of ownership makes Mill-Ex a very competitive solution.

Industries

Aerospace

Automotive

Heavy Duty

Medical

Others

Key product information

Maximum part size (diameter/length) [in]Maximum part size (diameter/length) [mm]

20 / 100520 / 2500

Rotay fixture Feed rates (rpm)

60 / customized

Travels (X / Y / Z / A1-A2 axis / A3 axis) [in]Travels (X / Y / Z / A1-A2 axis / A3 axis) [mm]

101 / 20 / 14 / ±190° / 180°2570 / 420 / 360 / ±190° / 180°

Maximum part size (width / height / length / maximum interference Ø) [in]Maximum part size (width / height / length / maximum interference Ø) [mm]

Depending on the location of the machining operations / 100 / Ø 20”Depending on the location of the machining operations / 2500 / Ø 520

Speed Aluminium Spindle (rpm)

24,000

Max. Weight (lbs)Max. Weight (kgs)

1102500

Number of tools (standard)

2 x 20 (20 tools for each spindle)

Tool Taper

HSK-63A

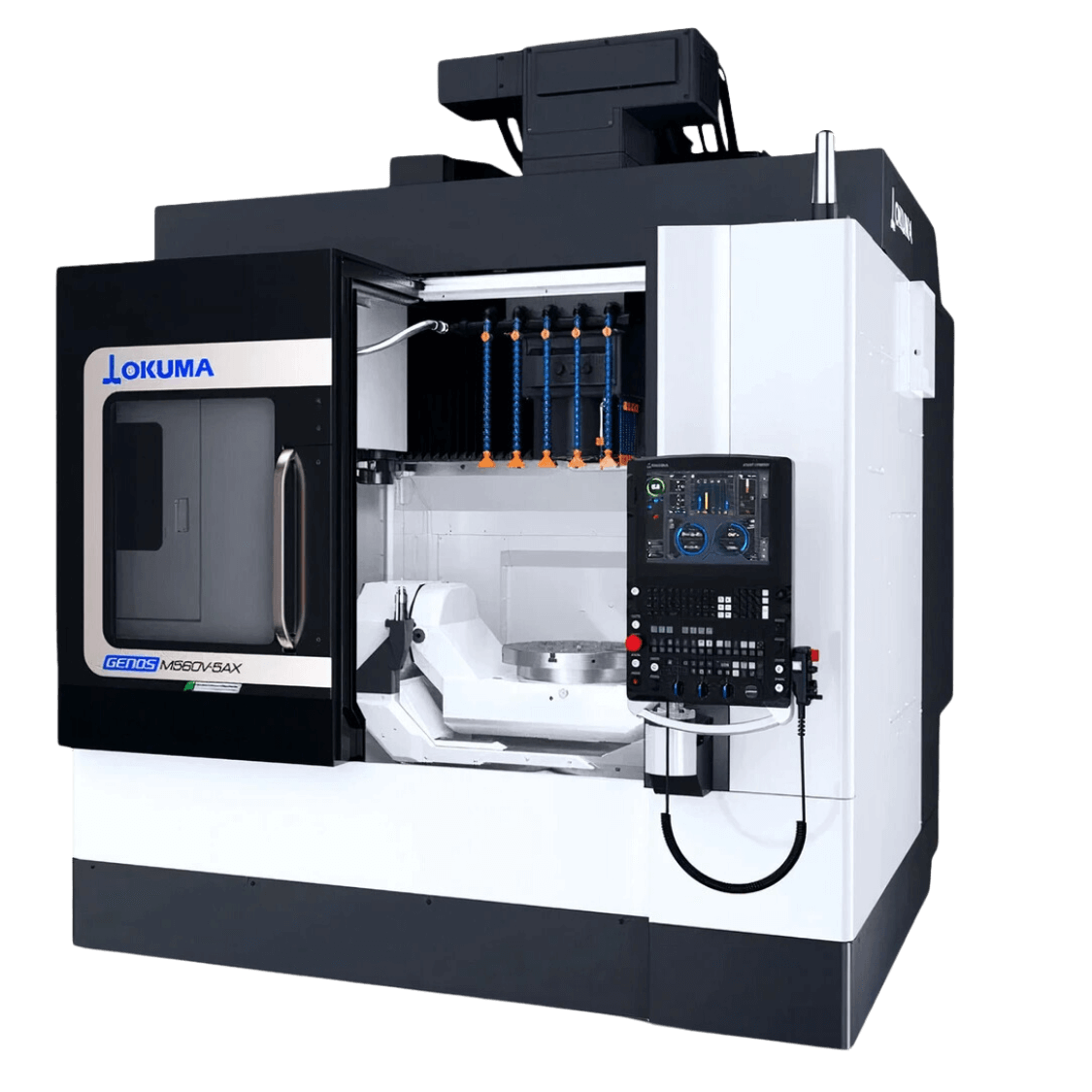

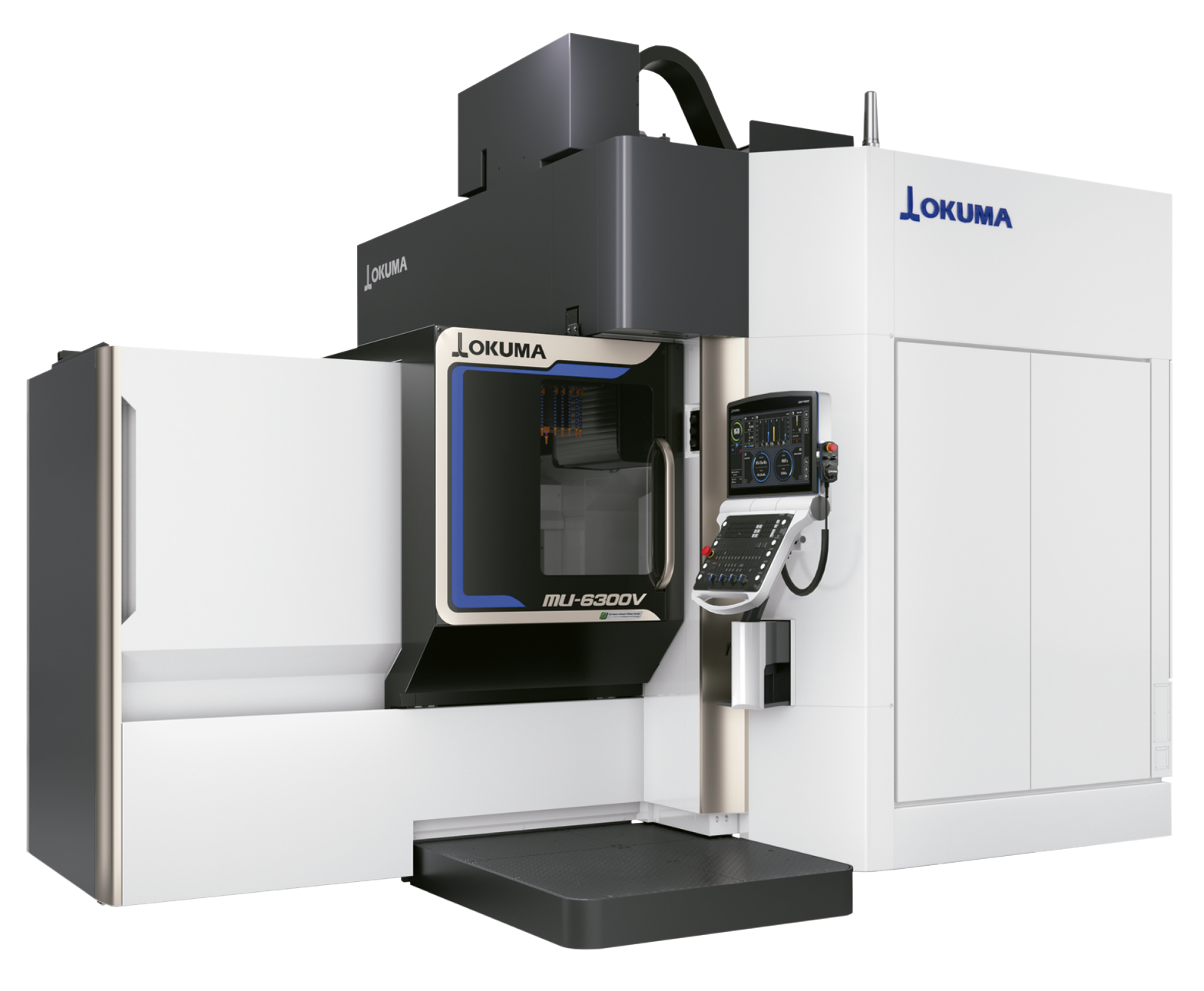

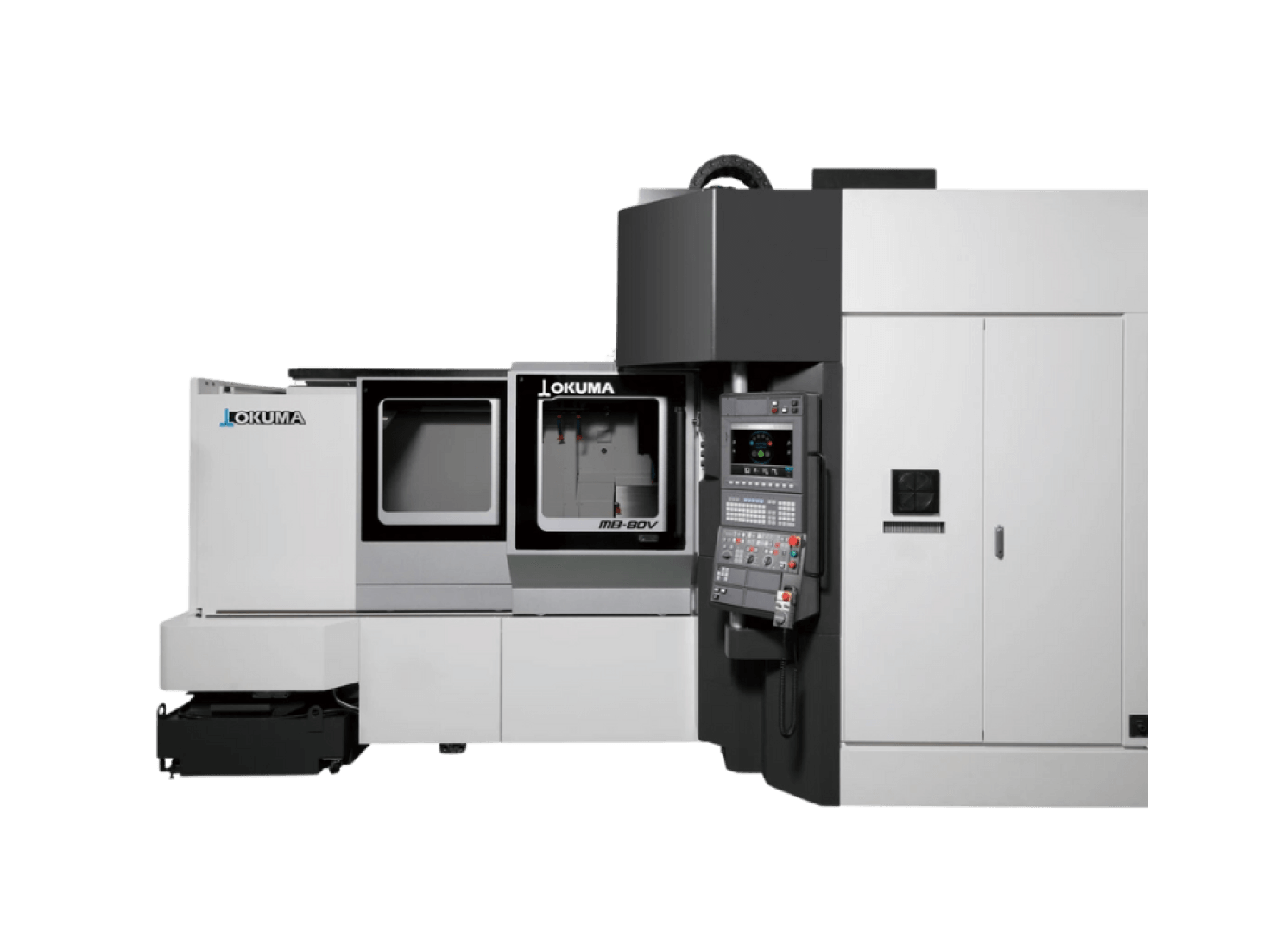

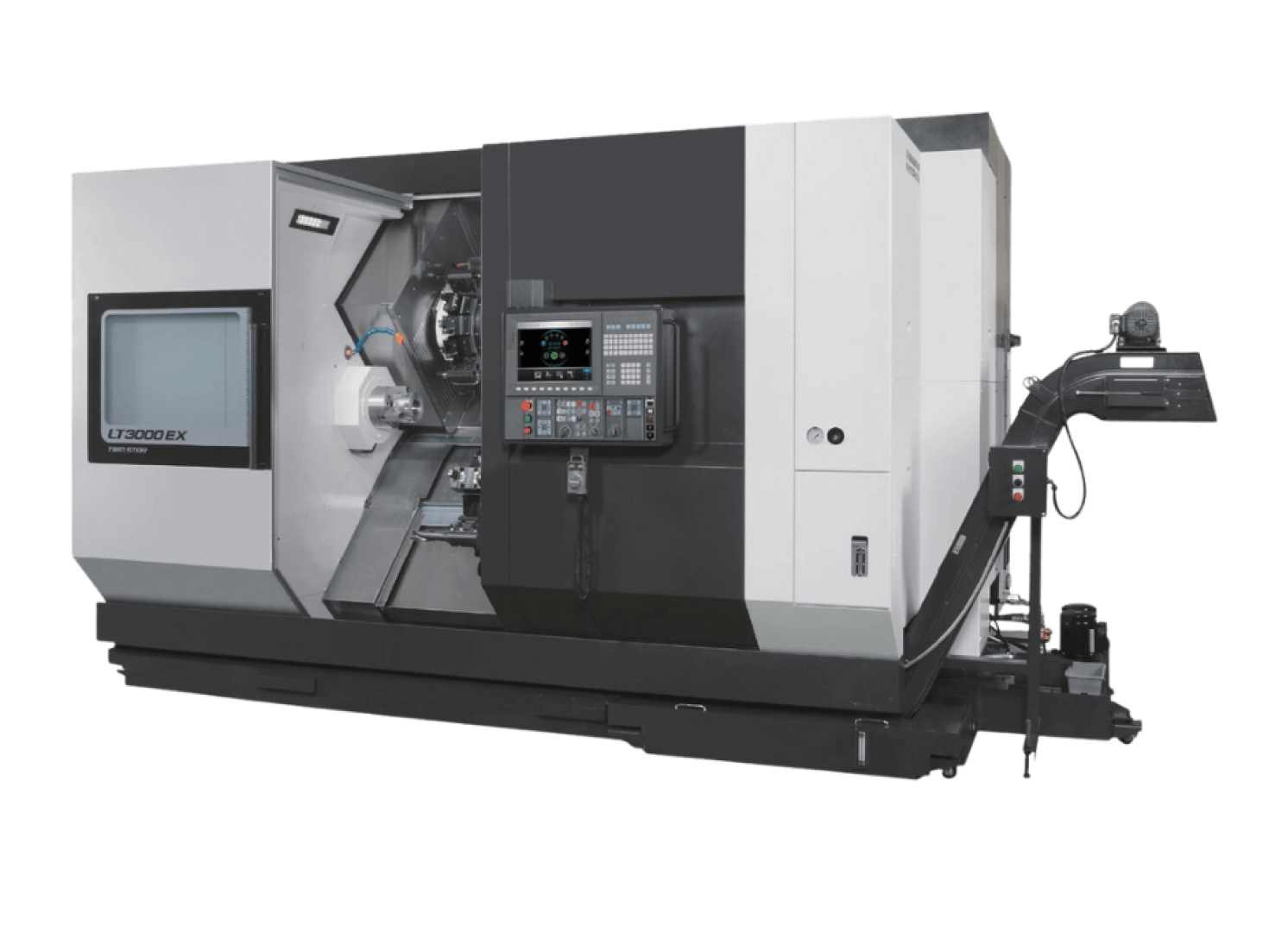

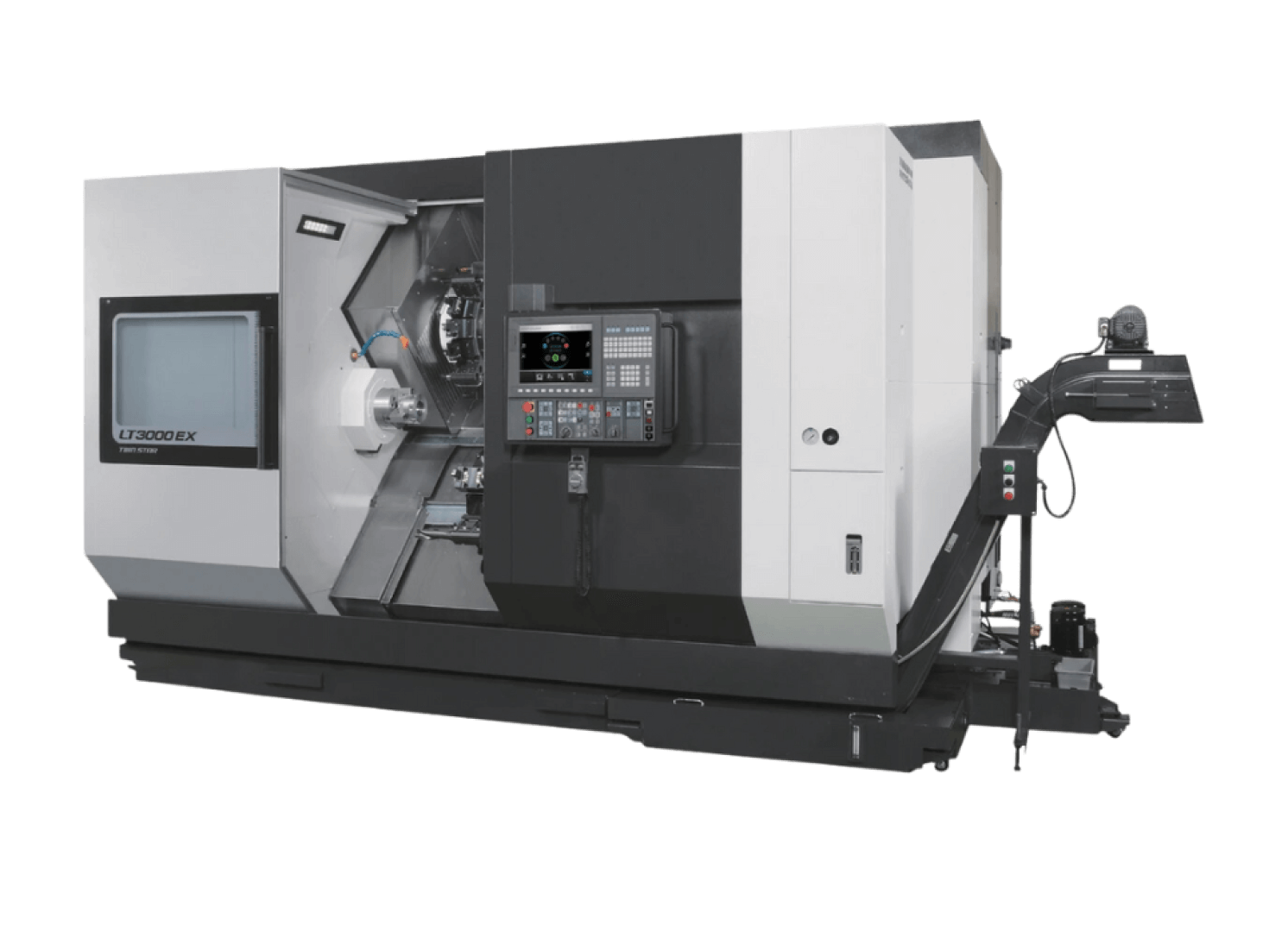

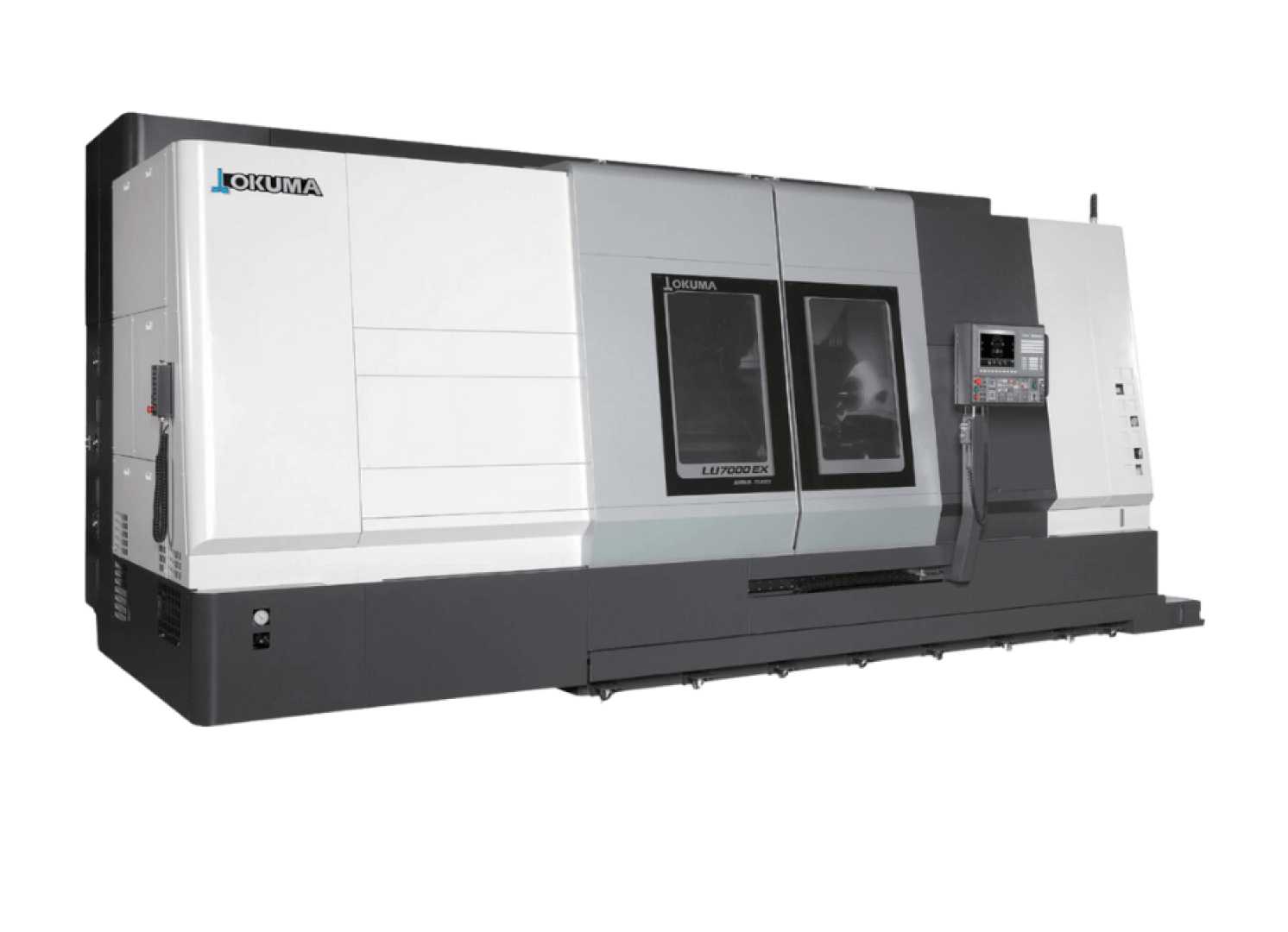

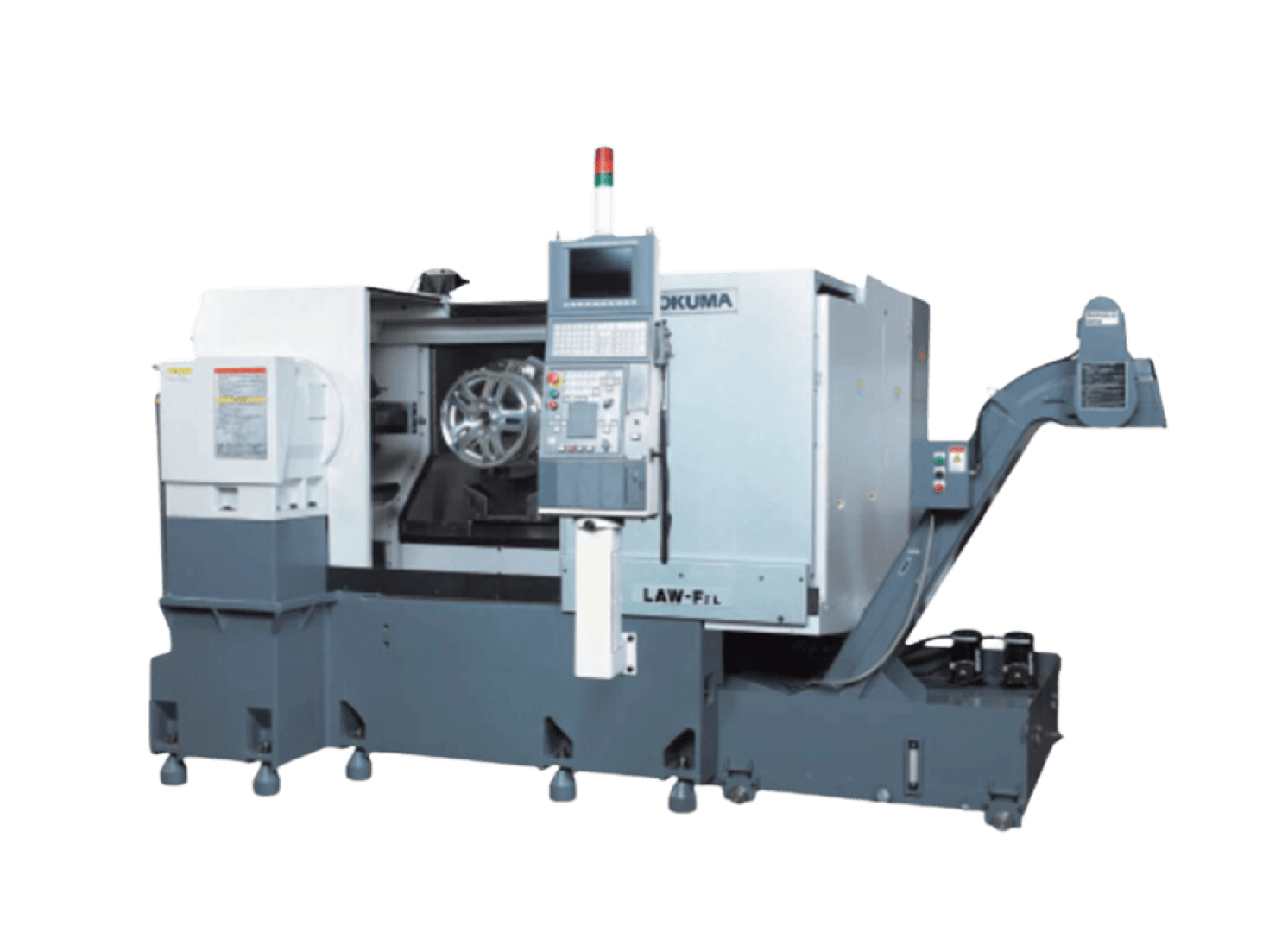

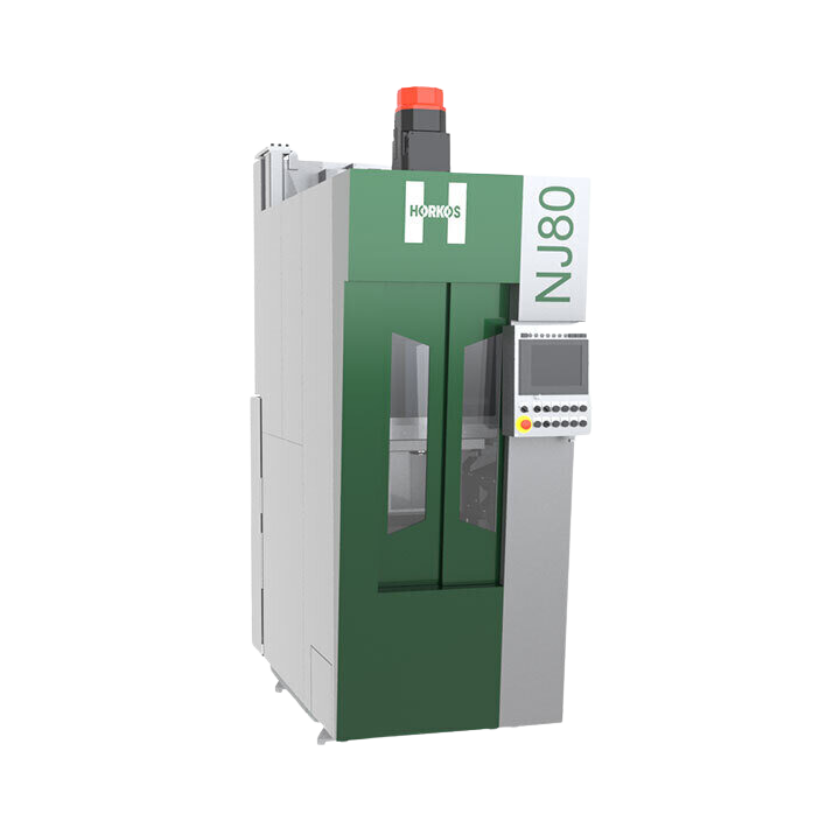

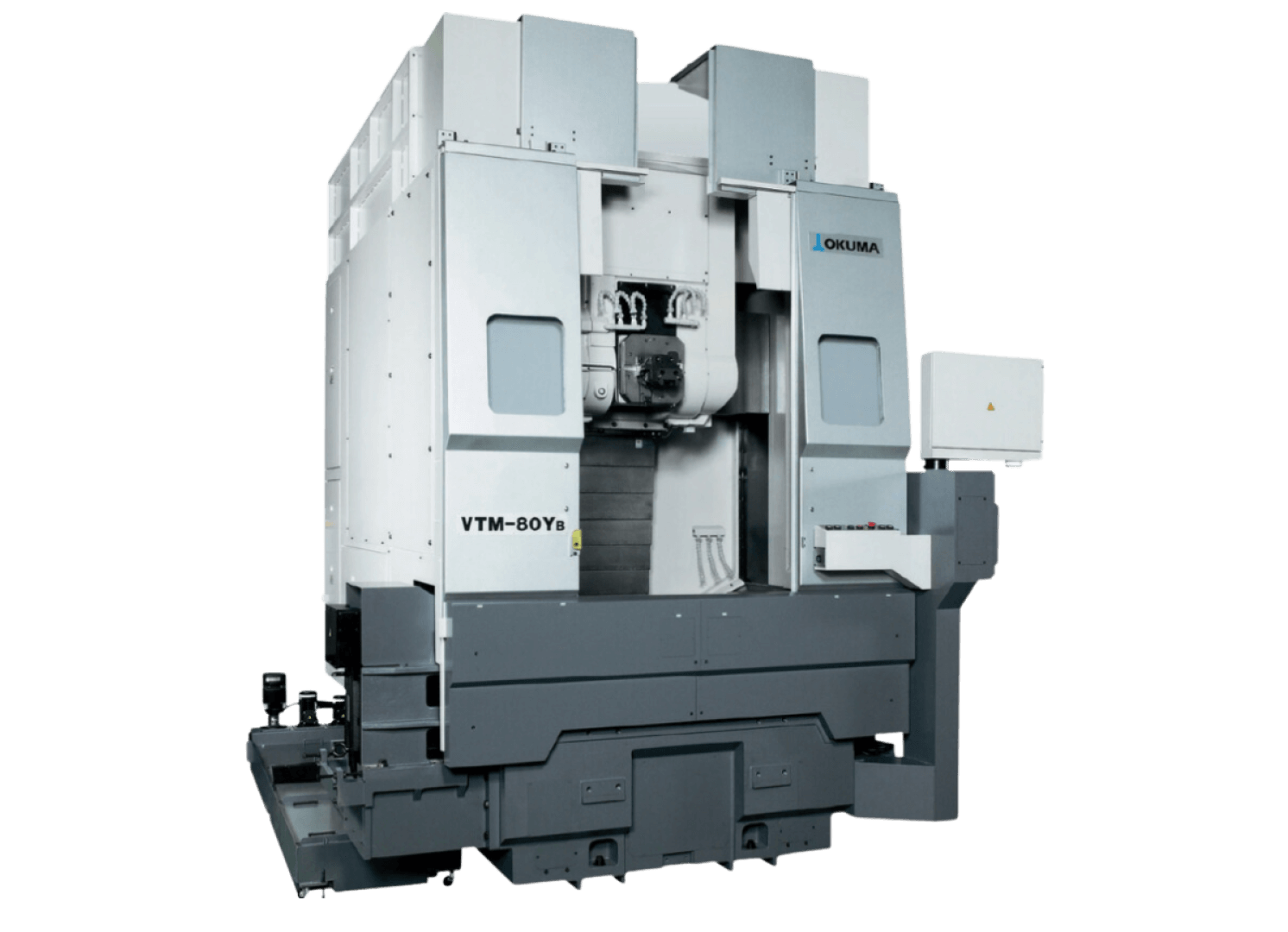

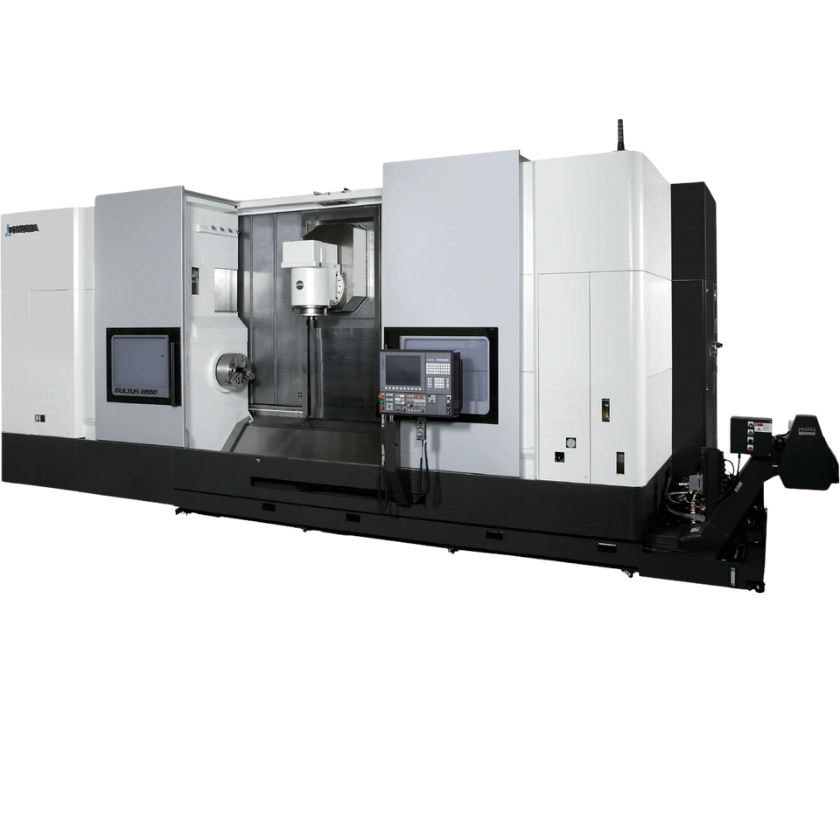

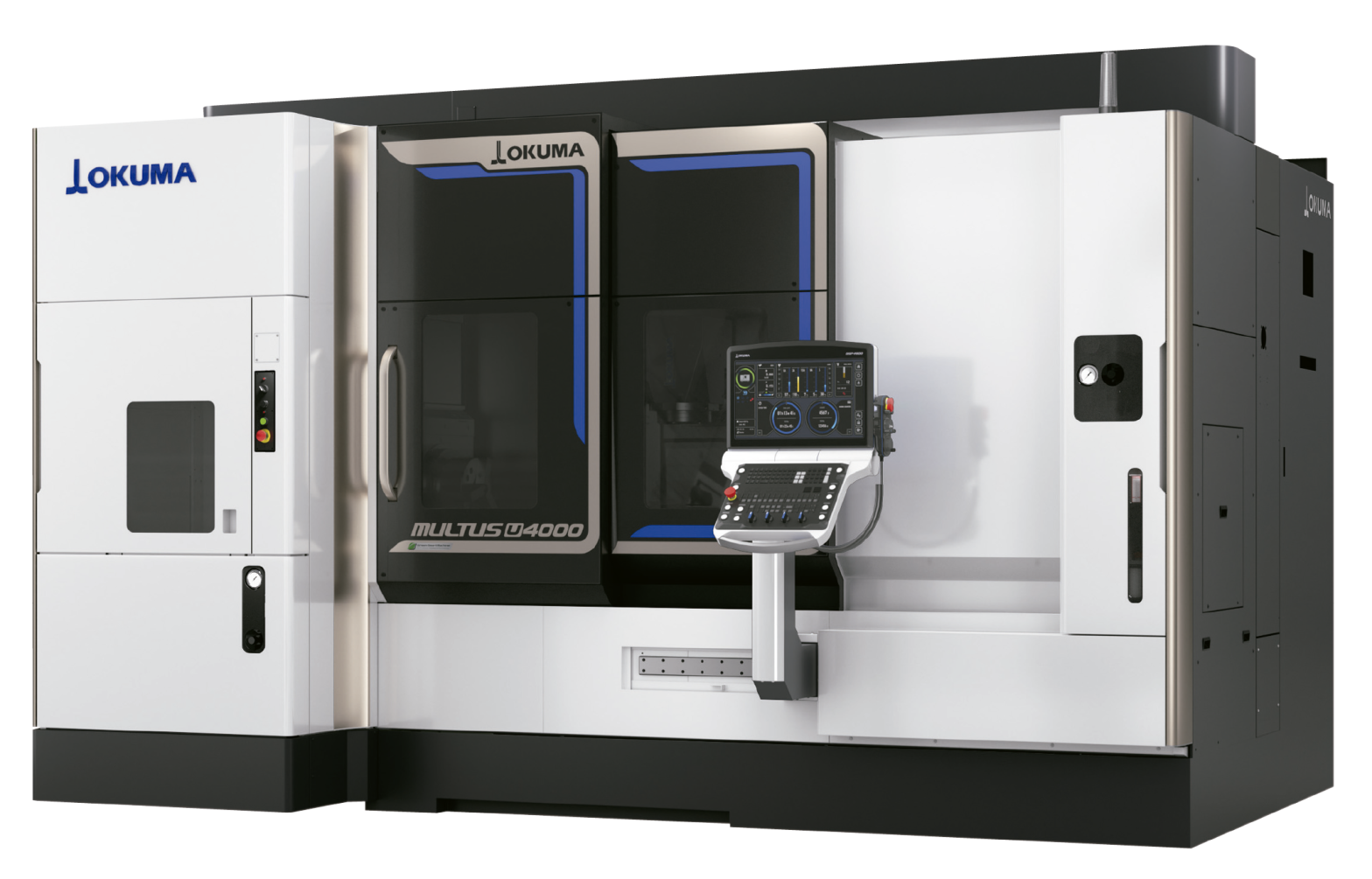

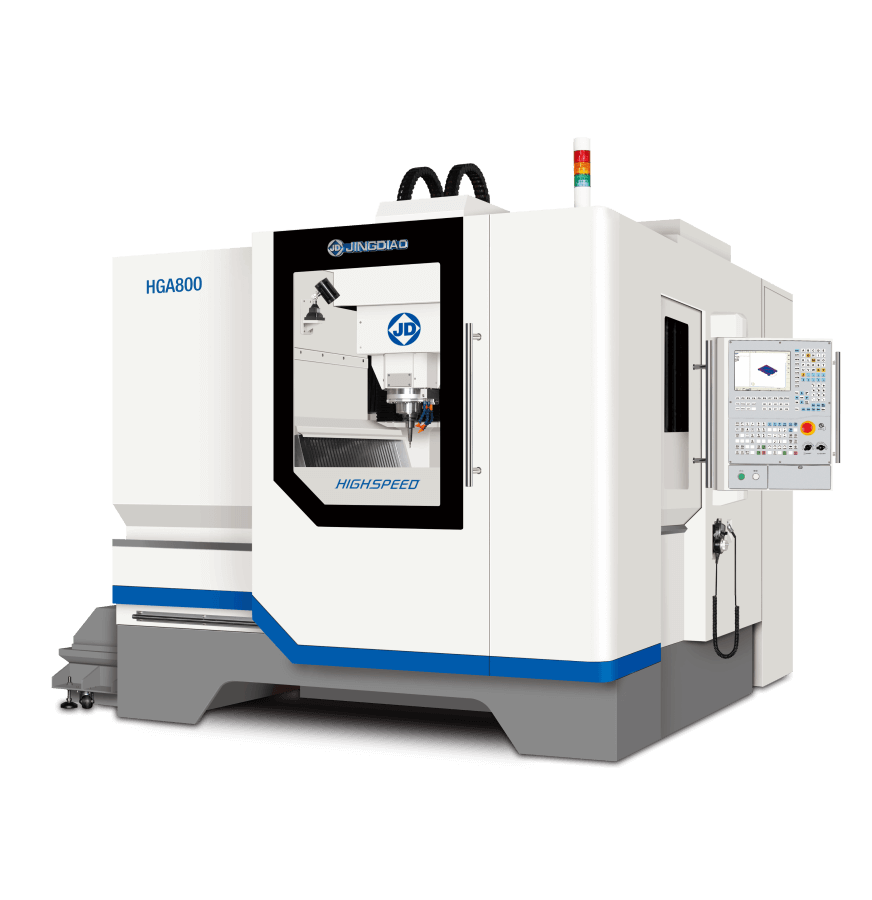

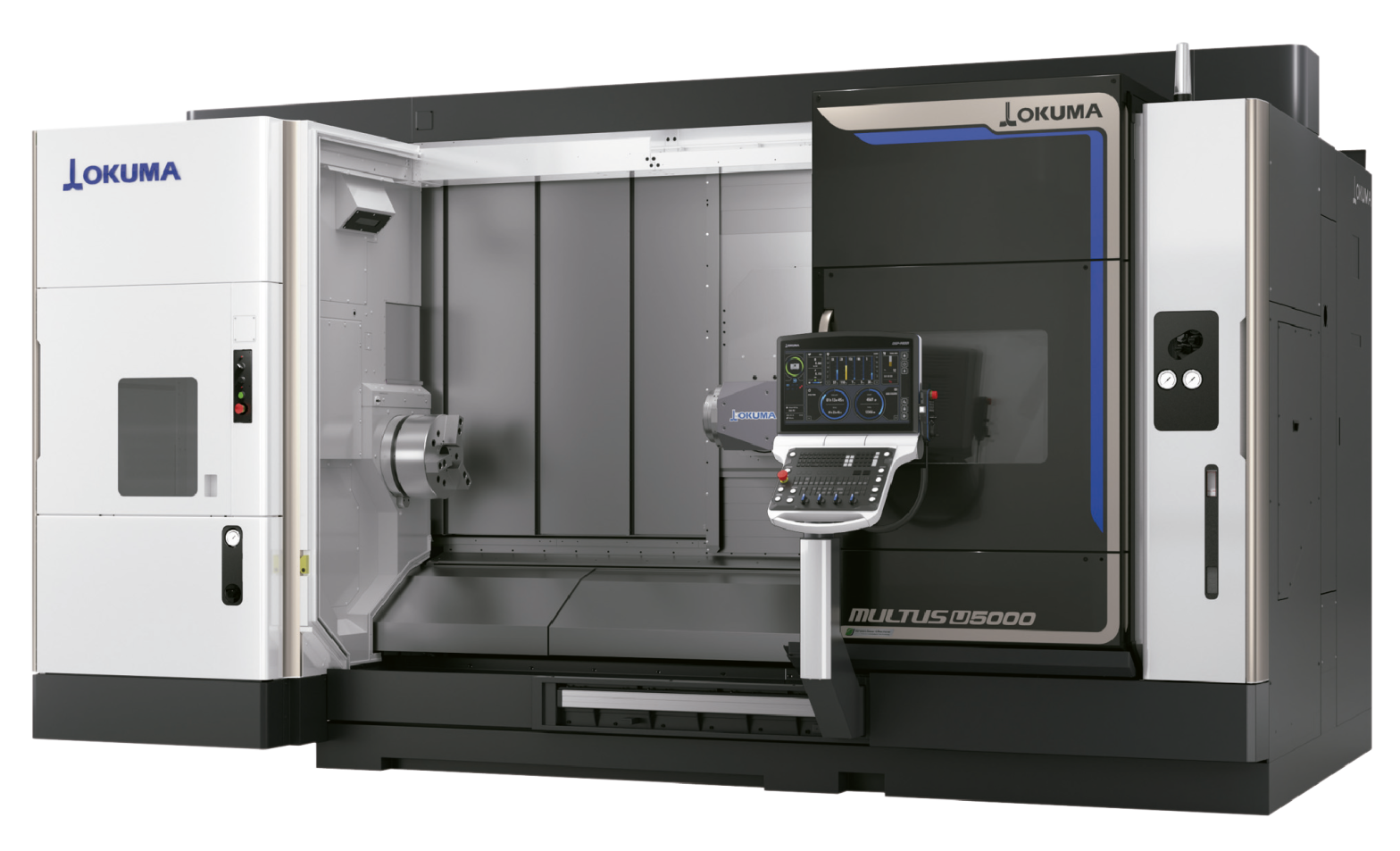

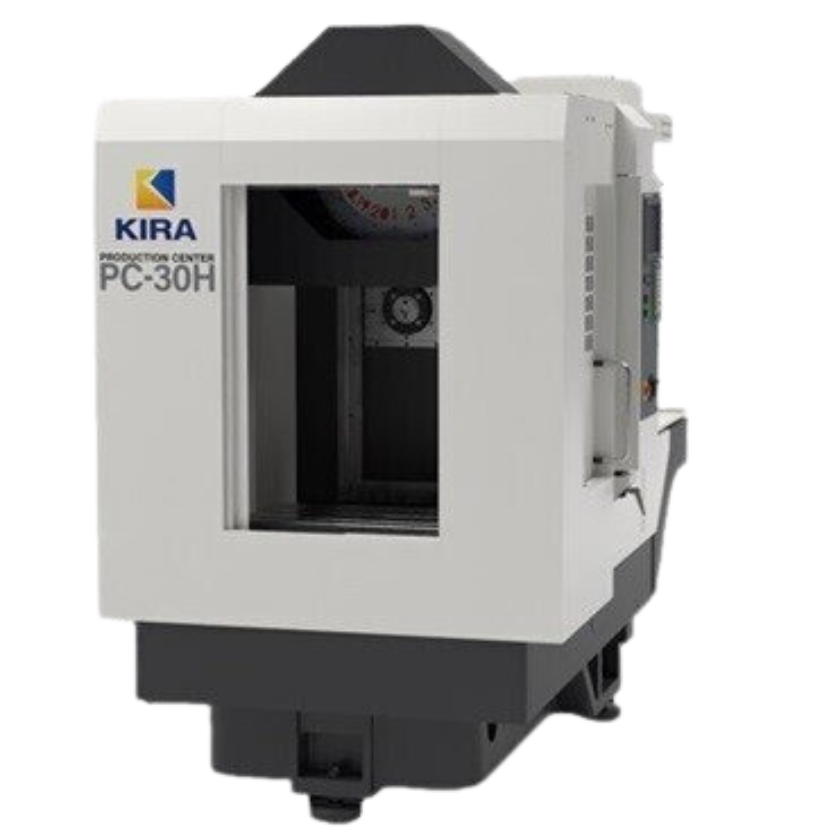

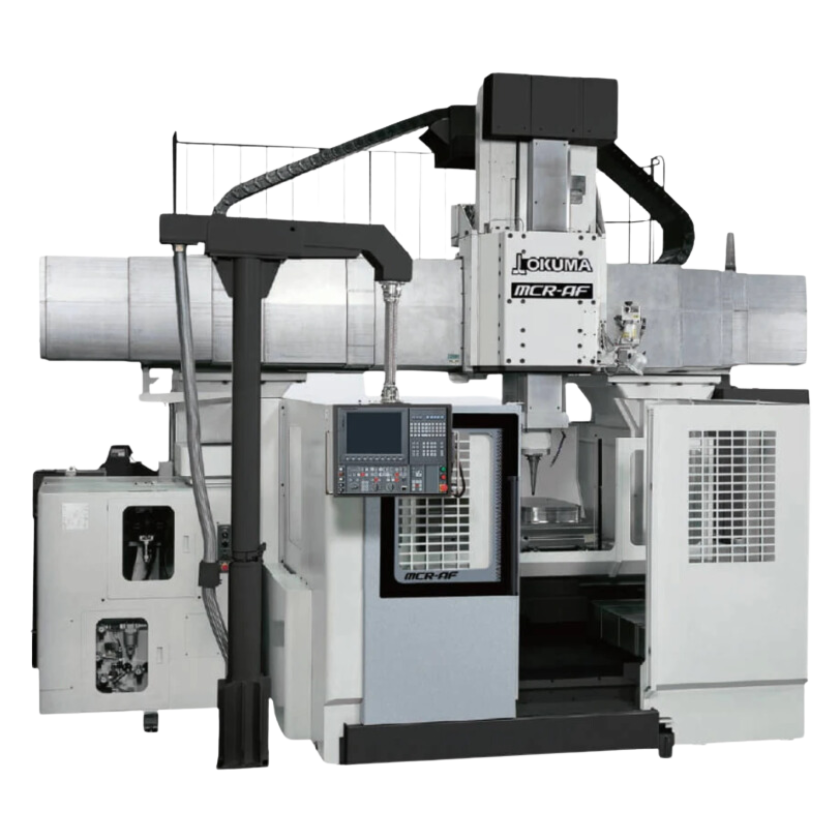

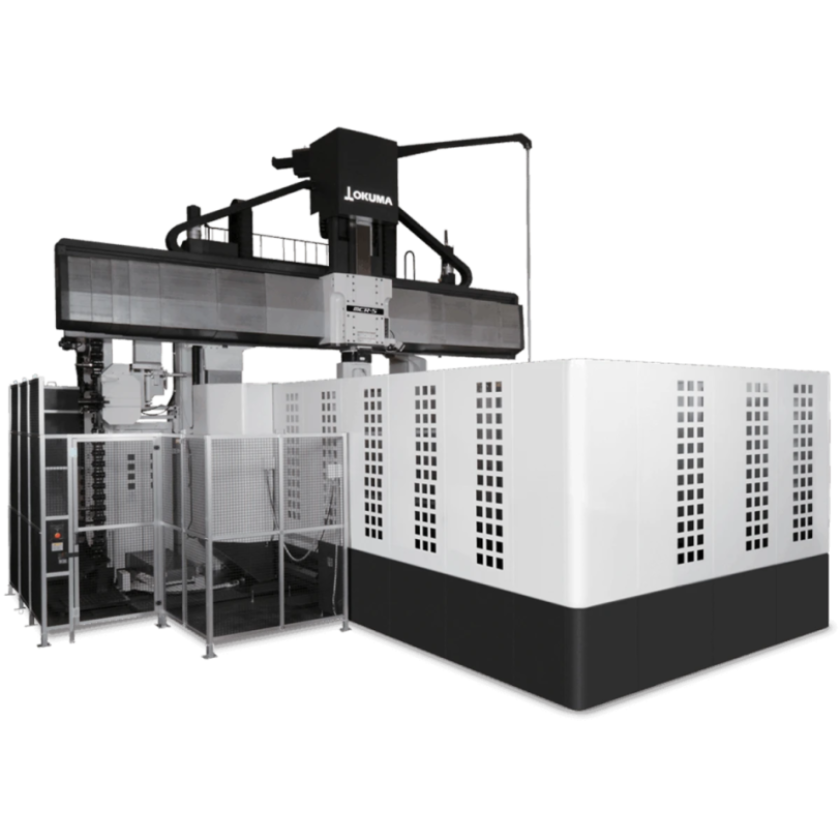

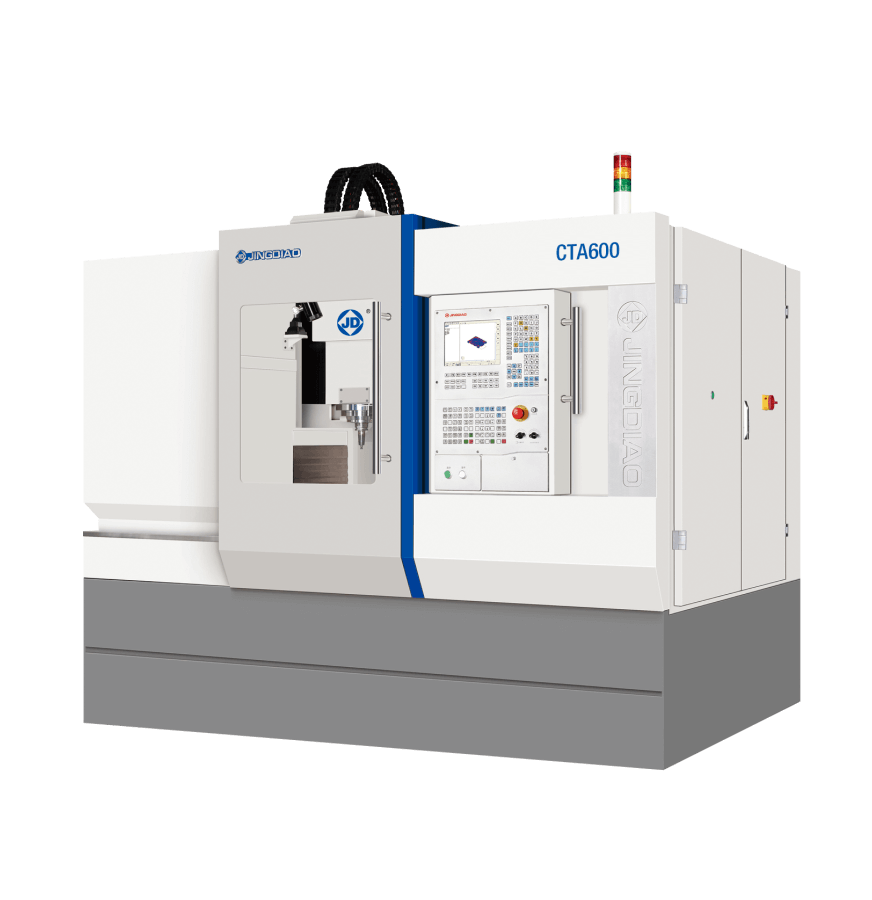

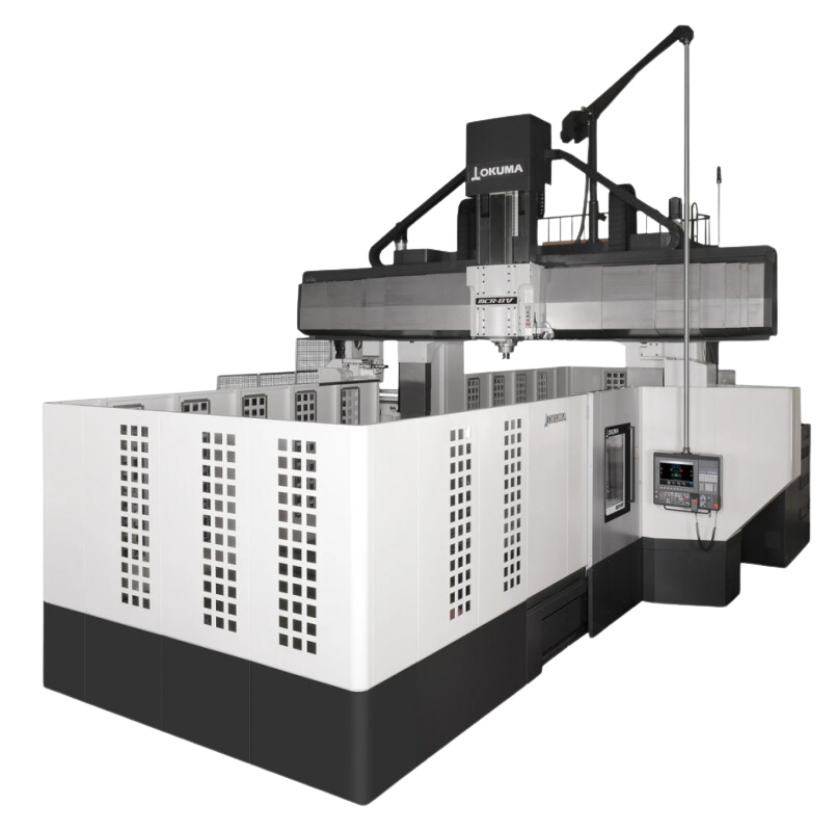

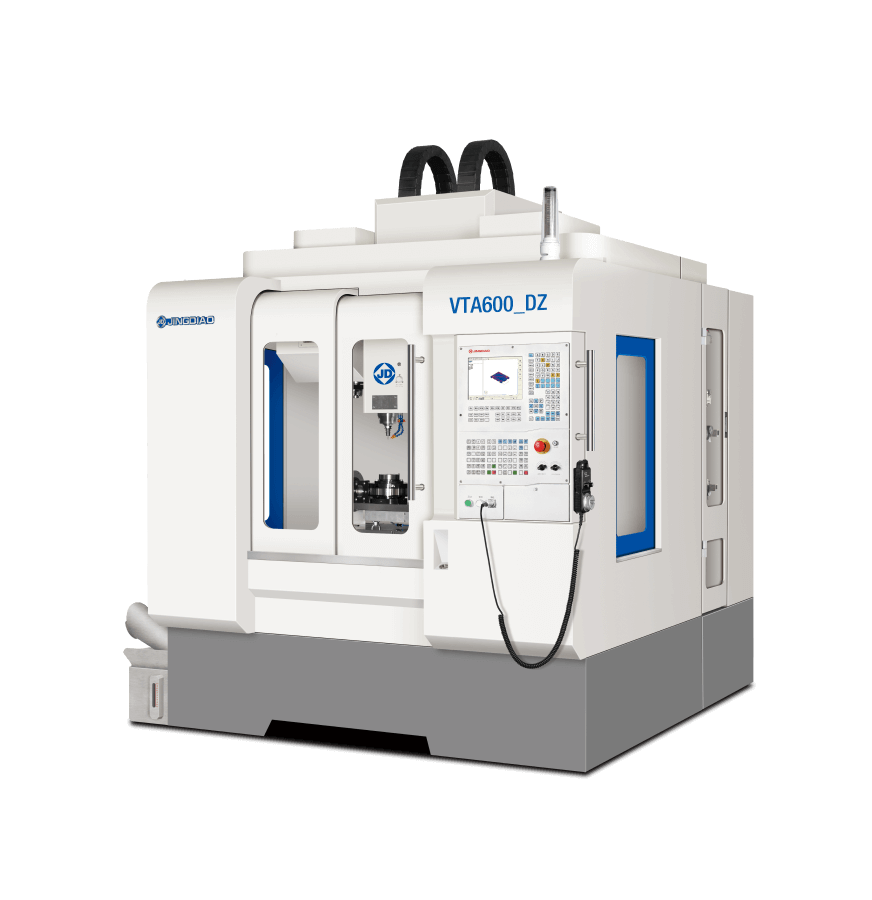

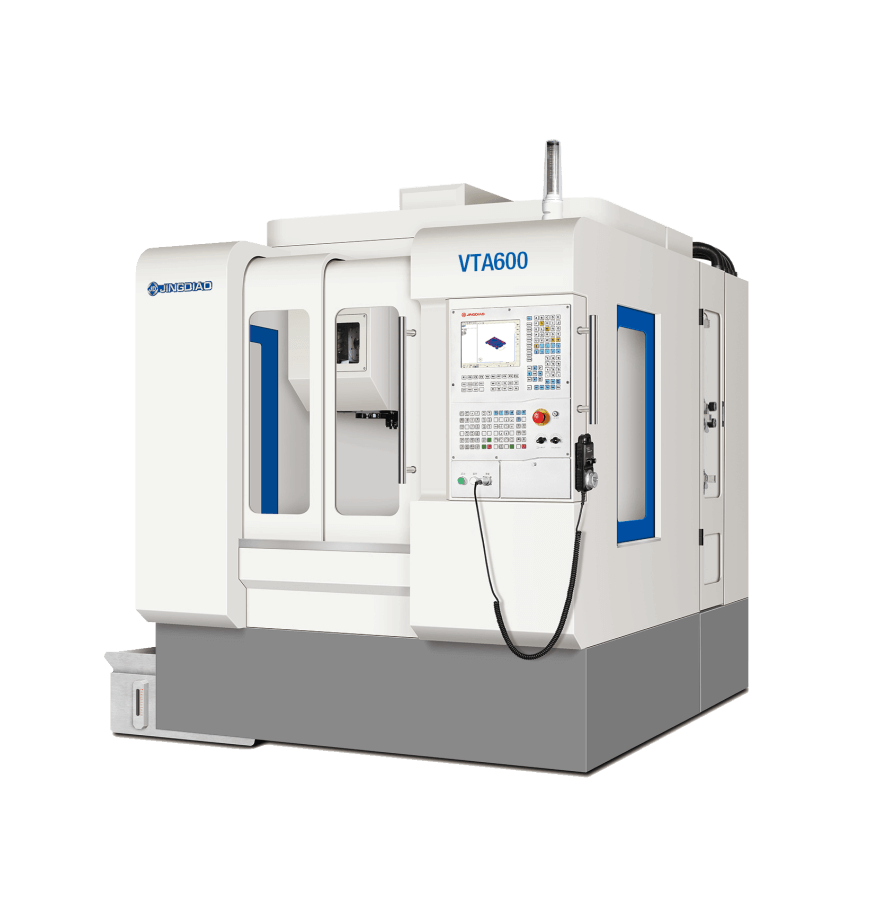

Combinaciones frecuentes para mejorar tus procesos en Tornos CNC, Centros de Maquinado CNC y demás Equipo para Mecanizado.

Equipe y maximice la productividad de sus Máquinas CNC con soluciones integrales

Creación y desarrollo de automatización industrial a la medida de sus necesidades