MODIG

MODIG

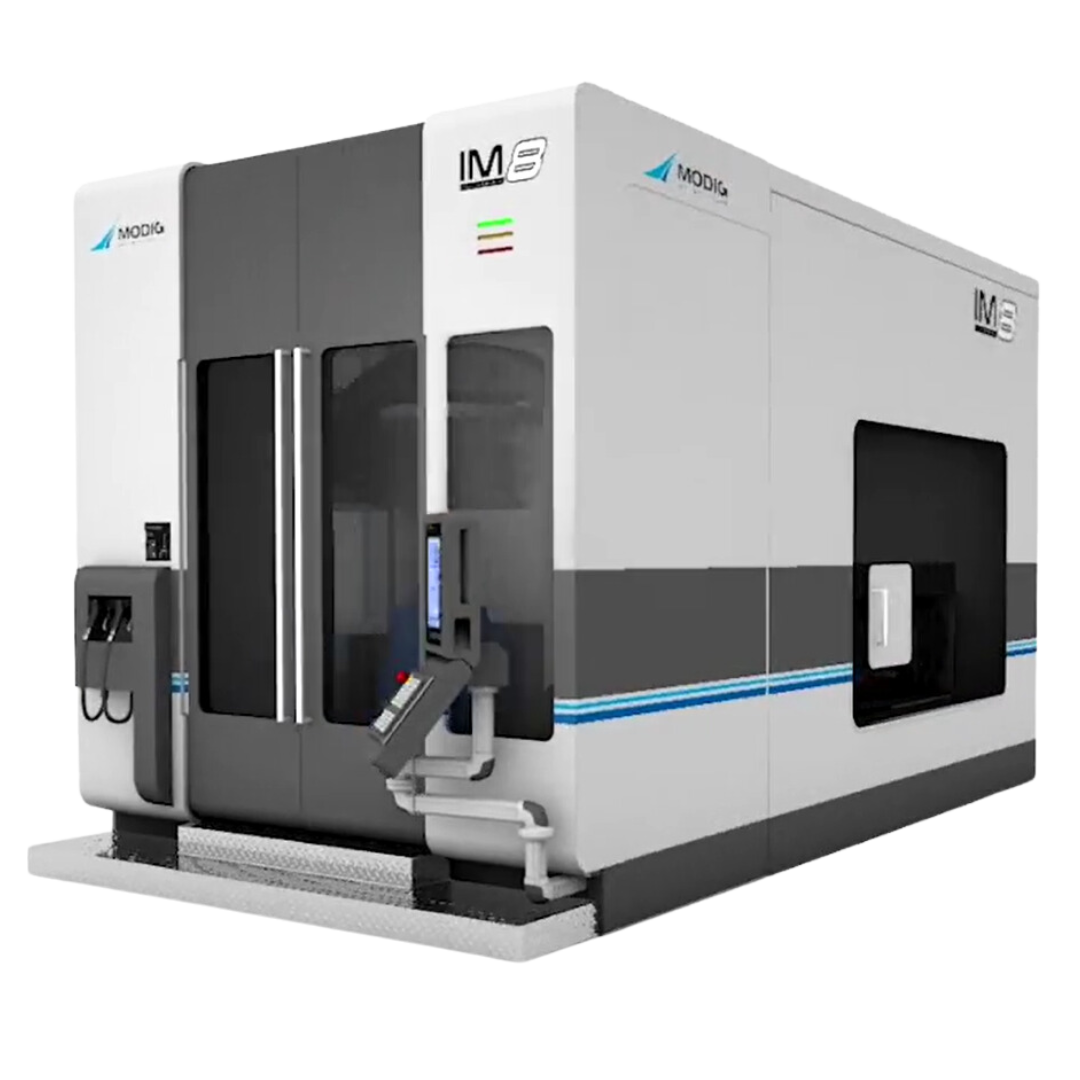

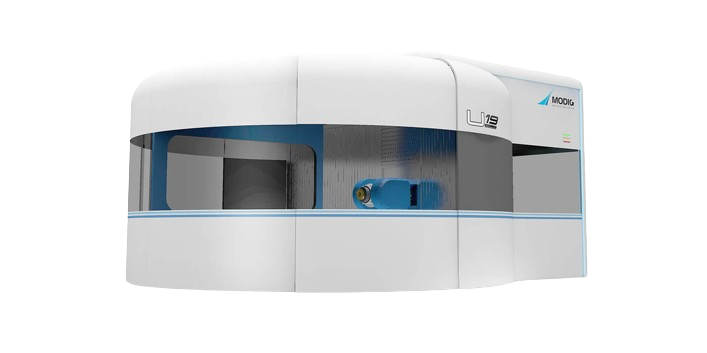

U19

Product description

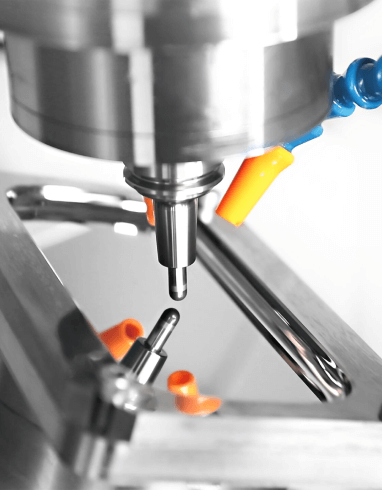

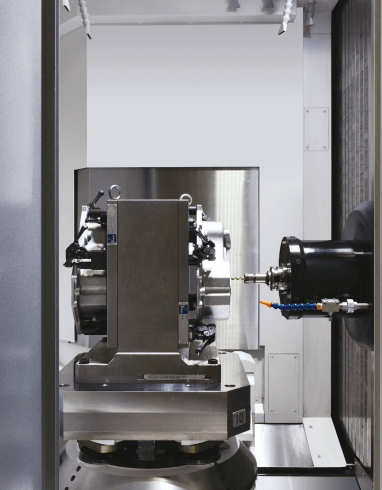

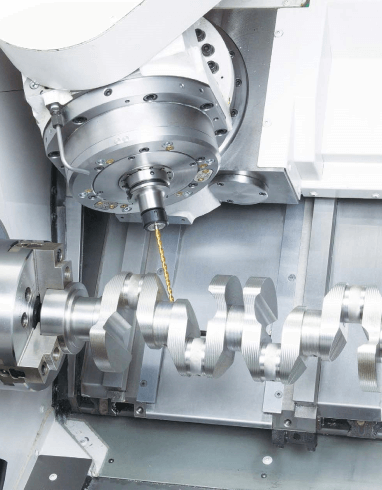

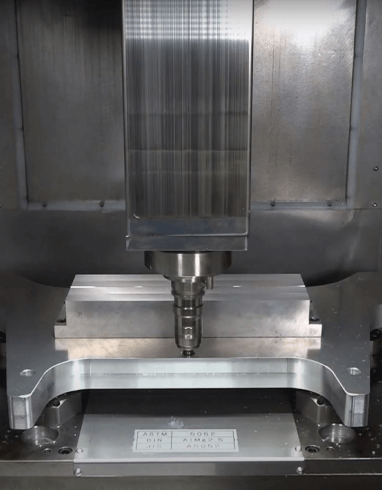

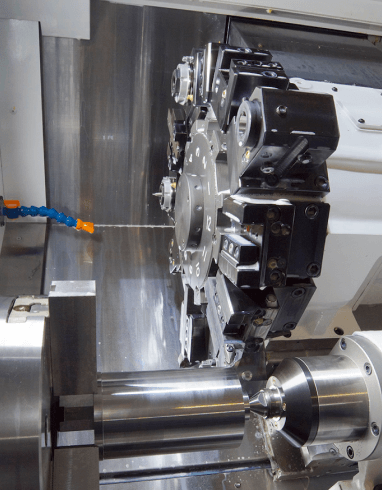

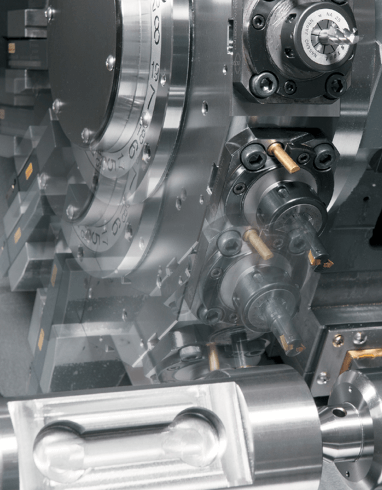

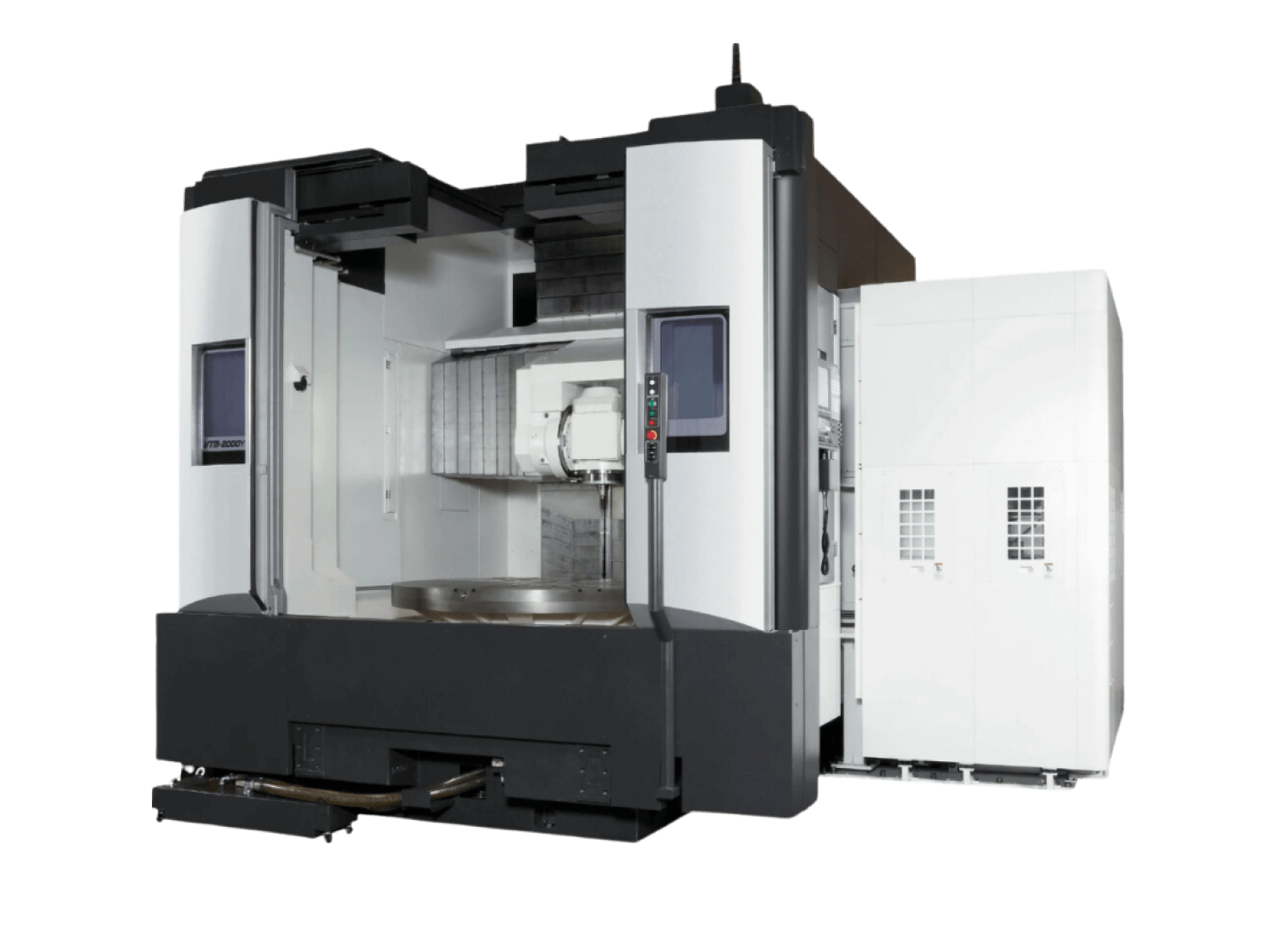

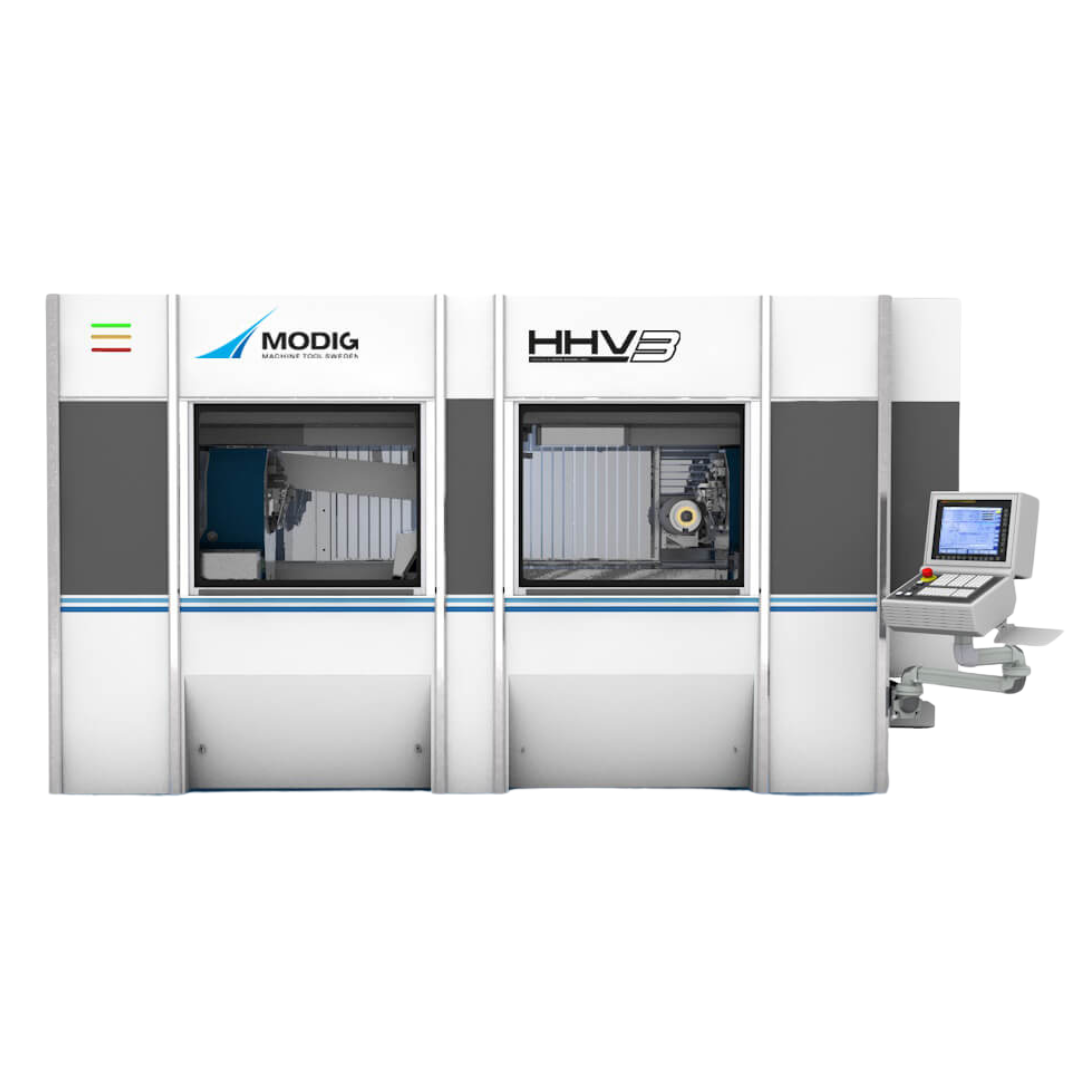

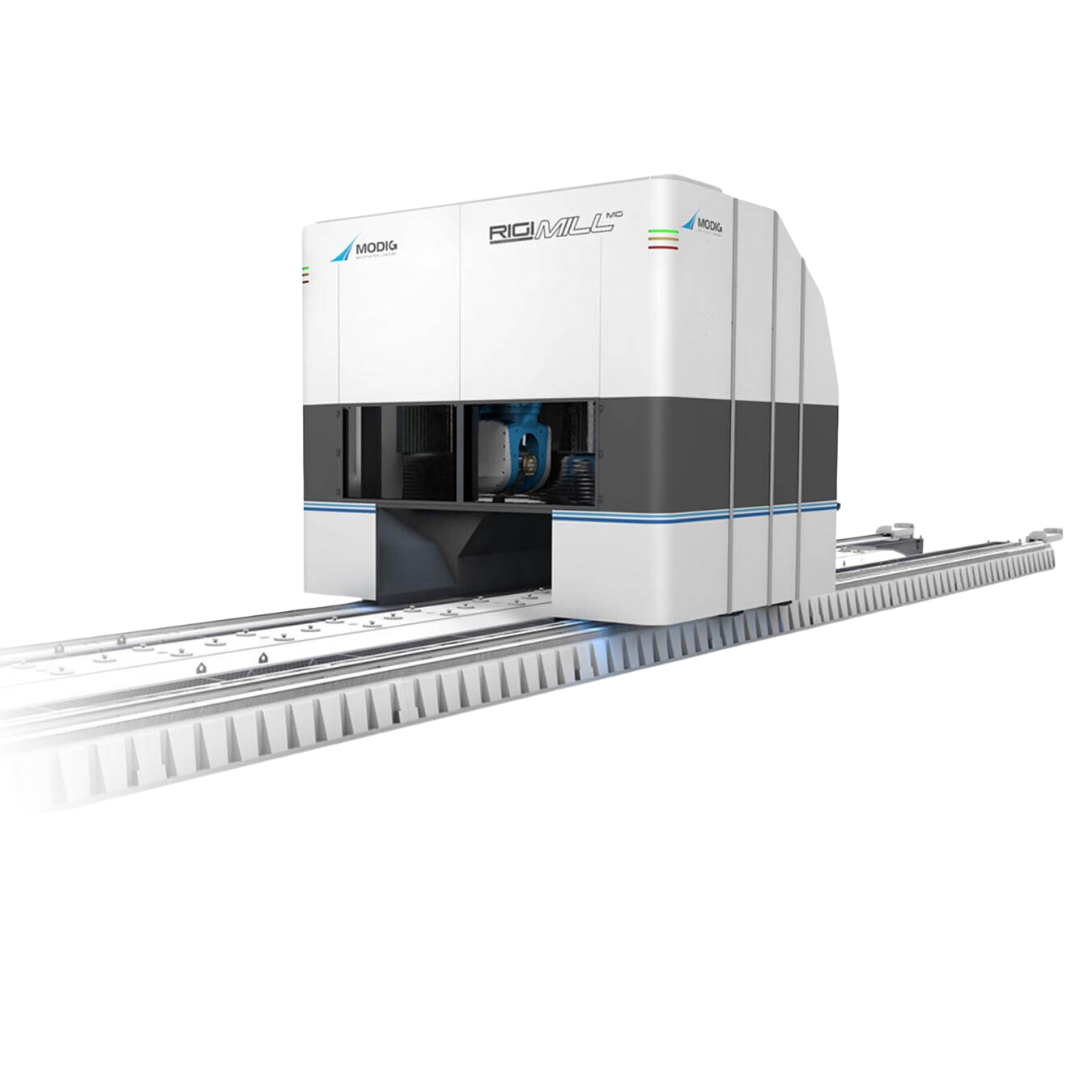

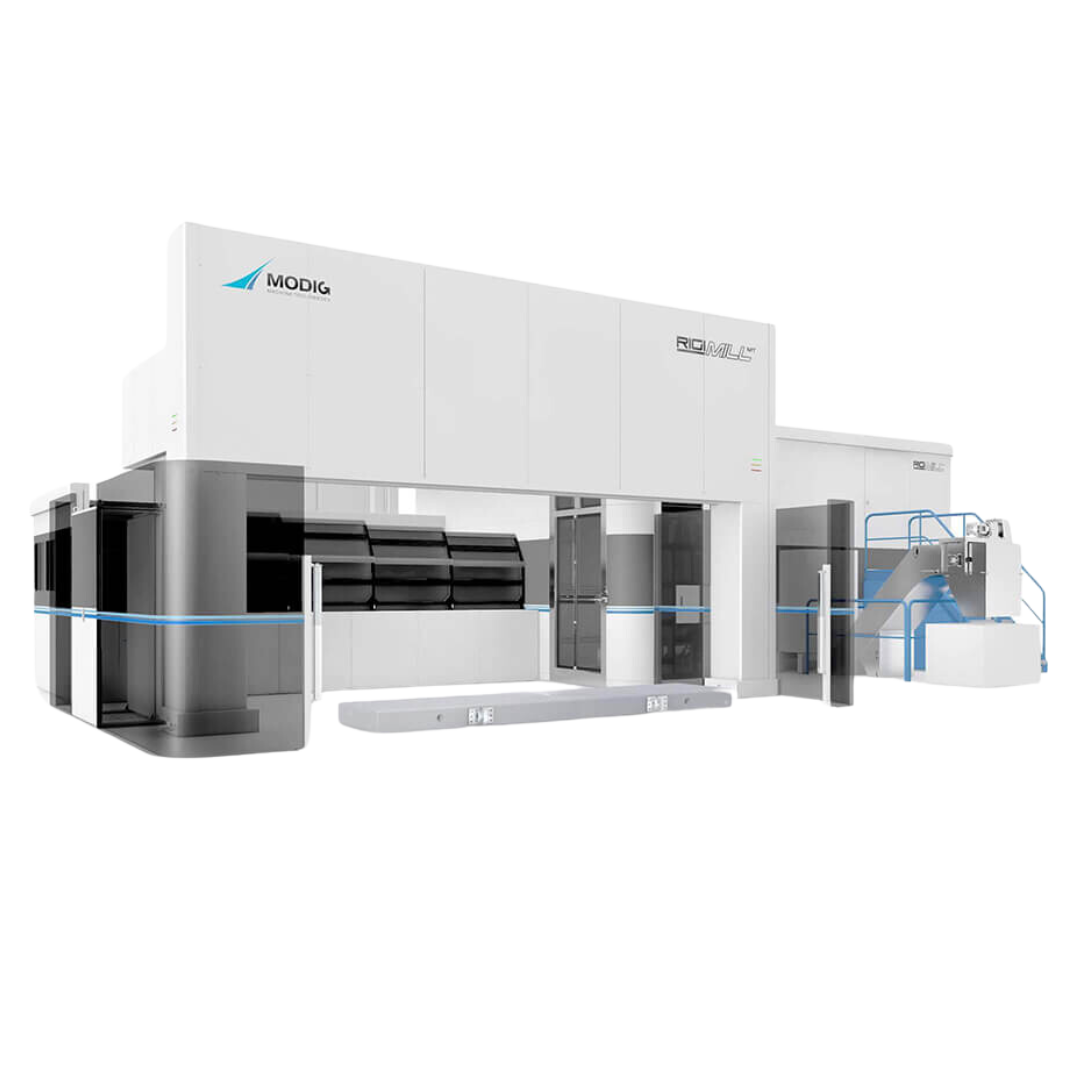

The U19 is a horizontal 5-axis machining center with dual zones containing two rotary tables right-sized for large casted components. Equipped with a single high-speed spindle able to perform dry and wet cutting, the U19 machines mega casting parts, including rear body structures, in the most efficient way. While the high-speed spindle effectively produces a precise result at extraordinary speed. The dual zones open up for ideal loading and unloading times, with a seamless process where the part loading in one zone could coincide without interfering with the machining of parts in the second zone. The machine is optimized for robotic automation to safeguard quick loading time and MODIG provides turnkey solutions for the entire production line.

Industries

Aerospace

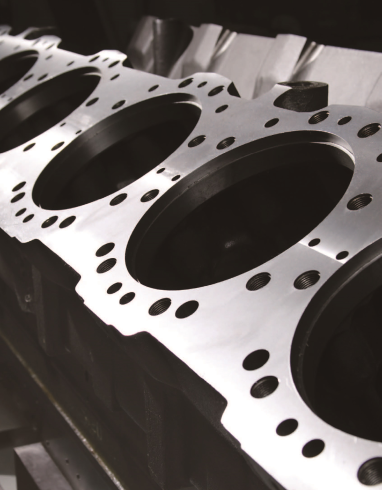

Automotive

Heavy Duty

Others

Key product information

Maximum part size (in)Maximum part size (mm)

80 x 80 x 552000 x 2000 x 1400

Rotary Table Size (in)Rotary Table Size (mm)

802000

Travels (X / Y / Z / C / A) [in]Travels (X / Y / Z / C / A) [mm]

160 / up to 55 / up to 60 / ±110° / ± 360°4000 / 1400 / 1500 / ±110° / ± 360°

Maximum cross section of the part (length / width / height) [in]Maximum cross section of the part (length / width / height) [mm]

80 x 80 x 552000 x 2000 x 1400

Rotary Table Speed (rpm)

2000

Aluminium Spindle Speed (rpm)

Up to 30,000

Hard Metal Spindle Speed (rpm)

12,000

Maximum load (Ib)Maximum load (kg)

11,0005,000

Number of tools (standard)

Up to 100

Tool Taper

Tool Taper

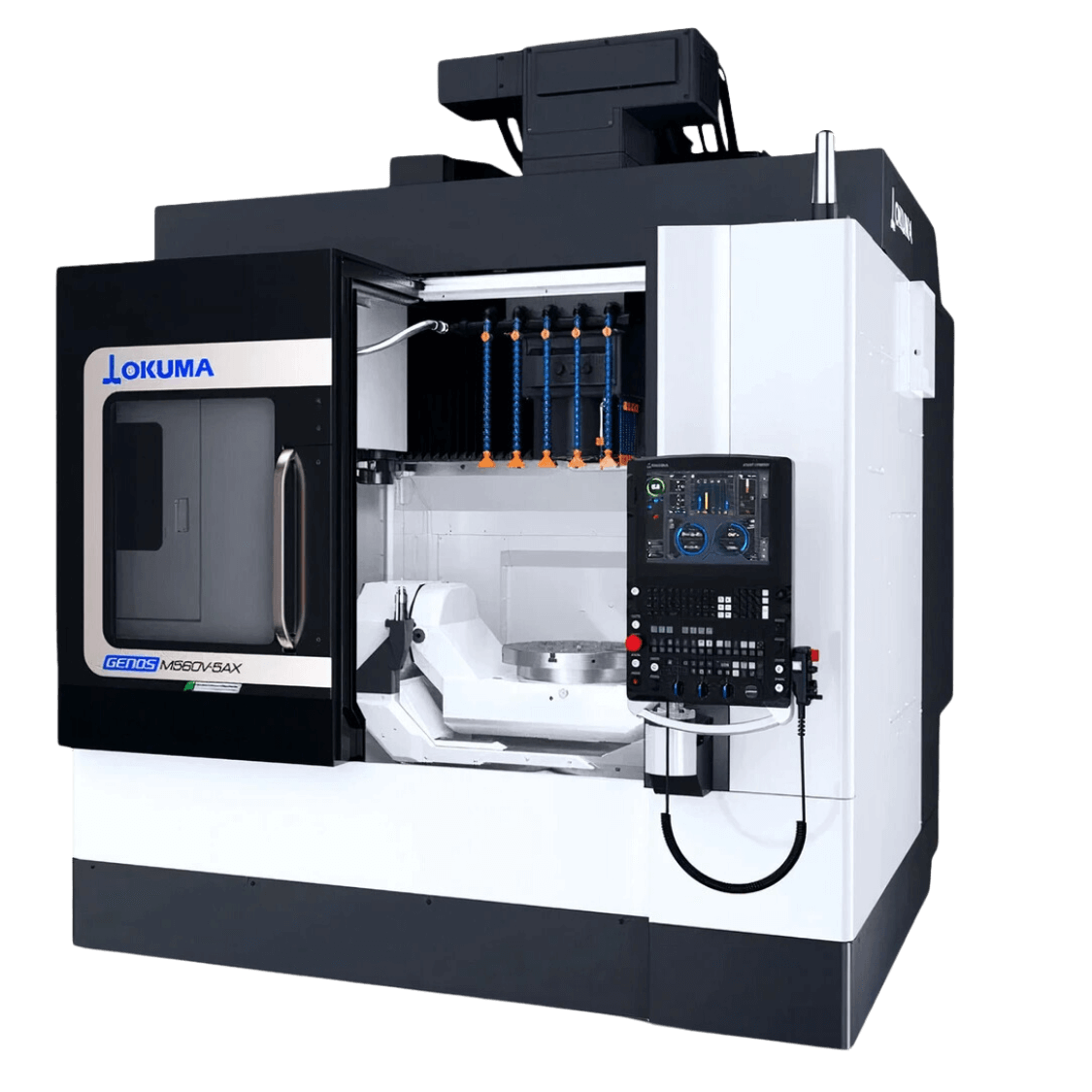

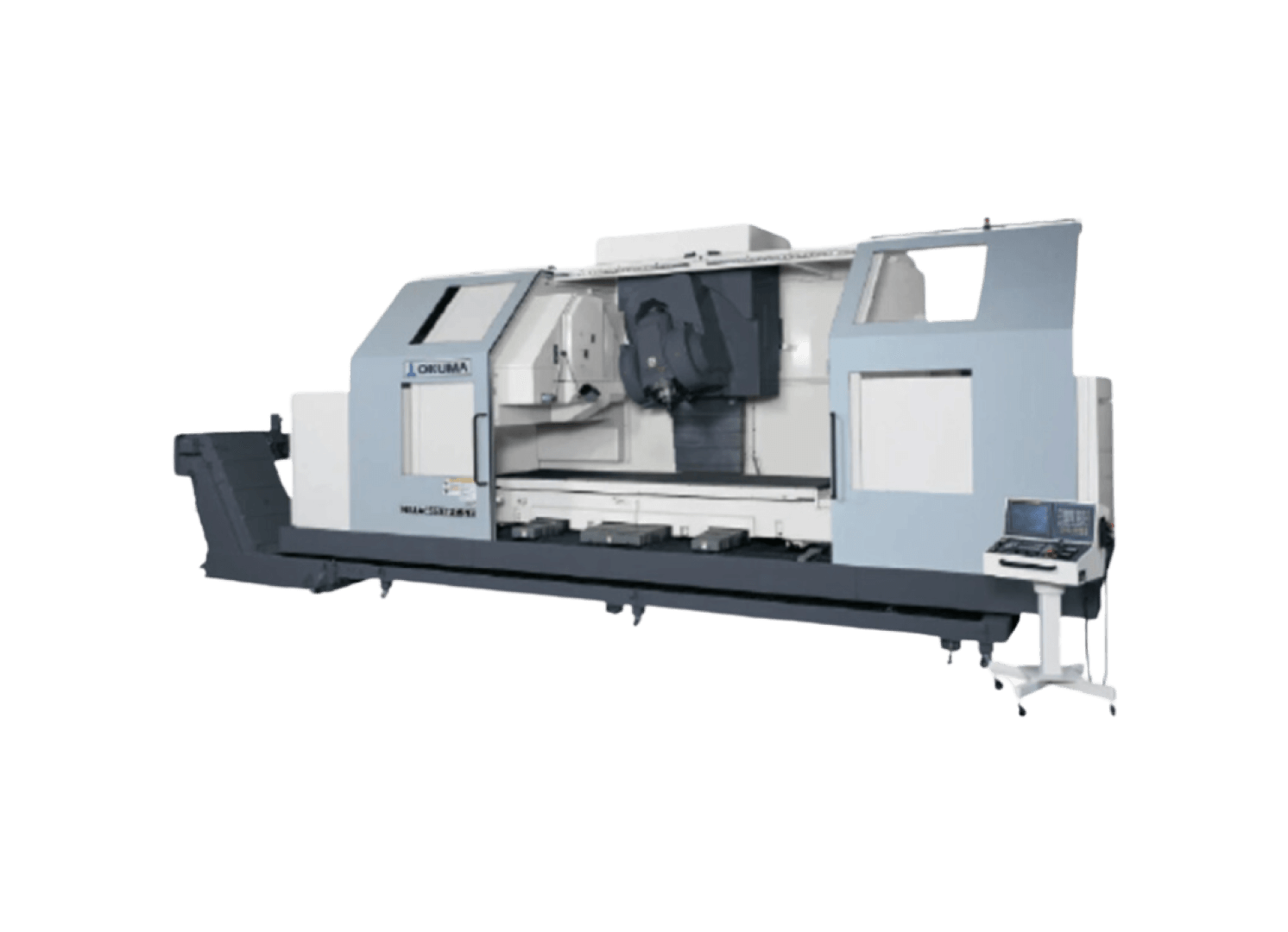

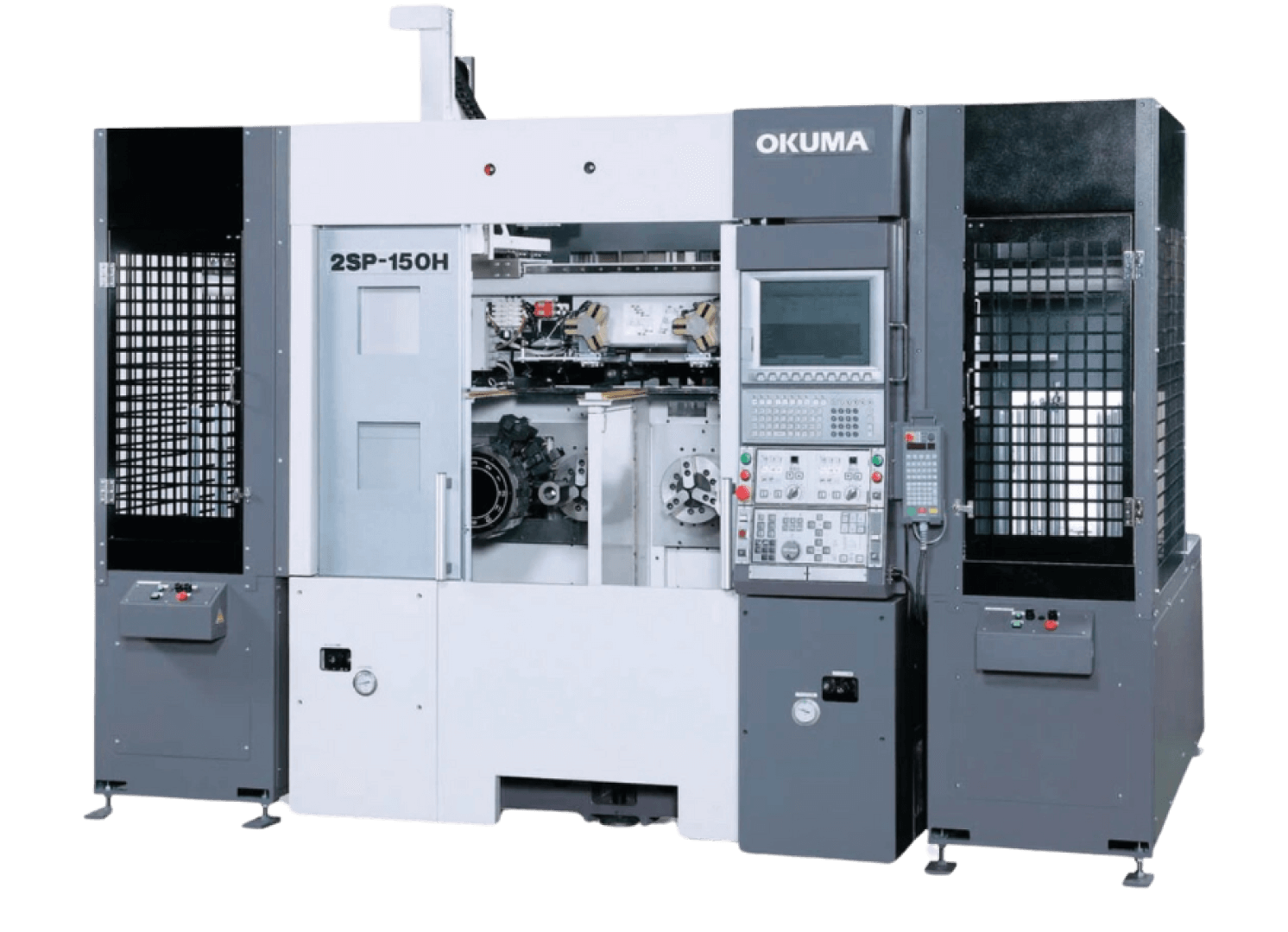

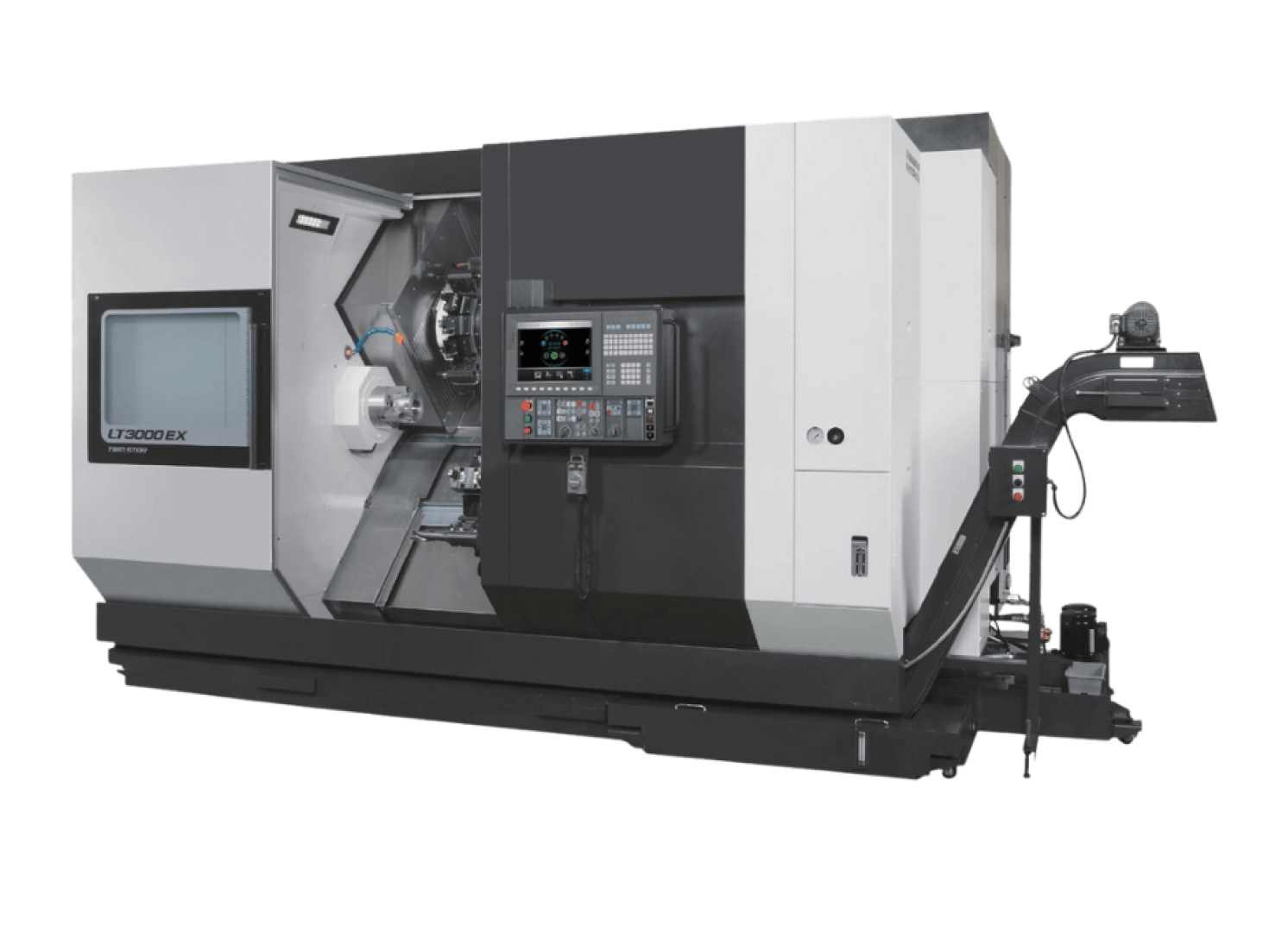

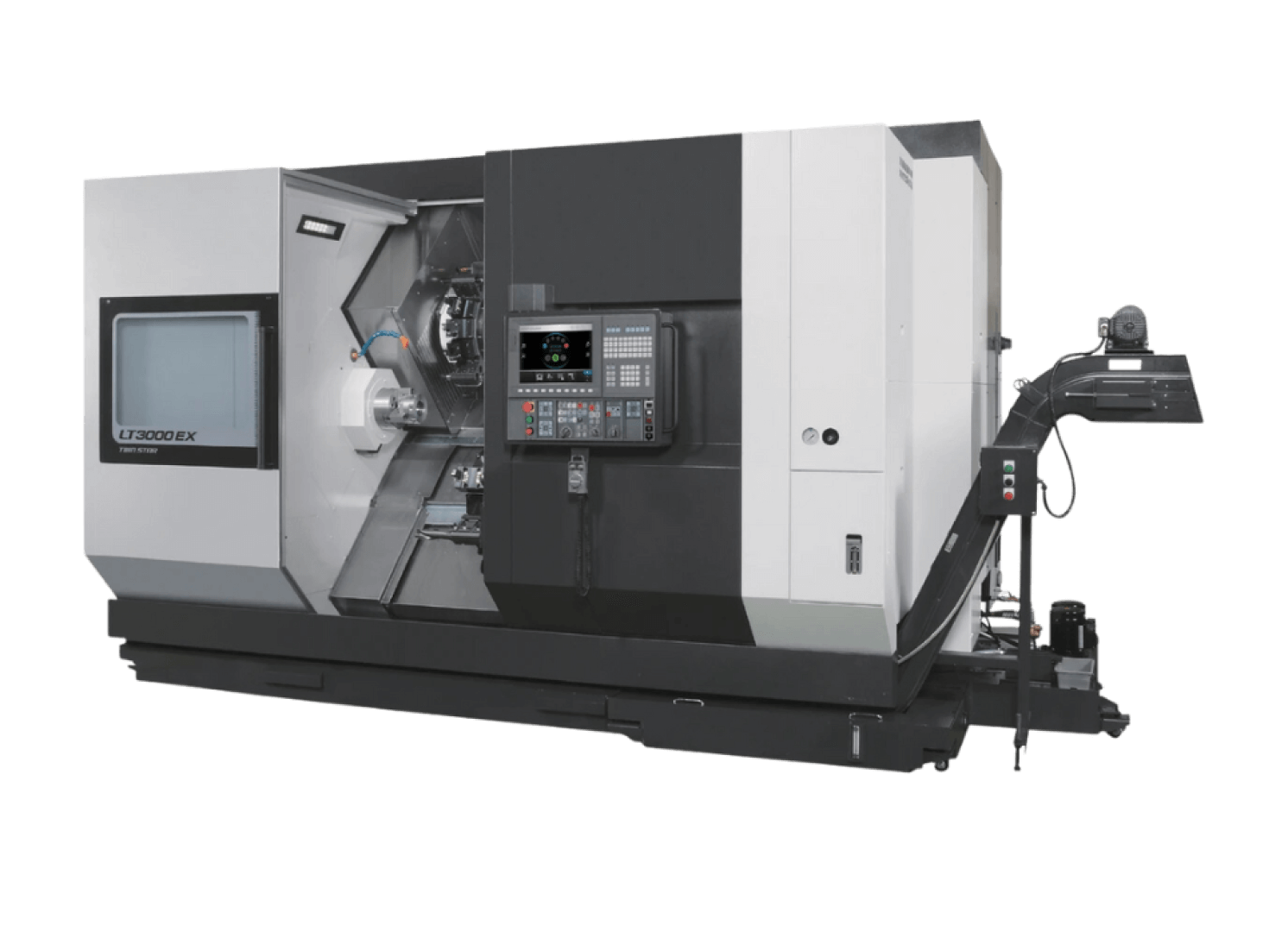

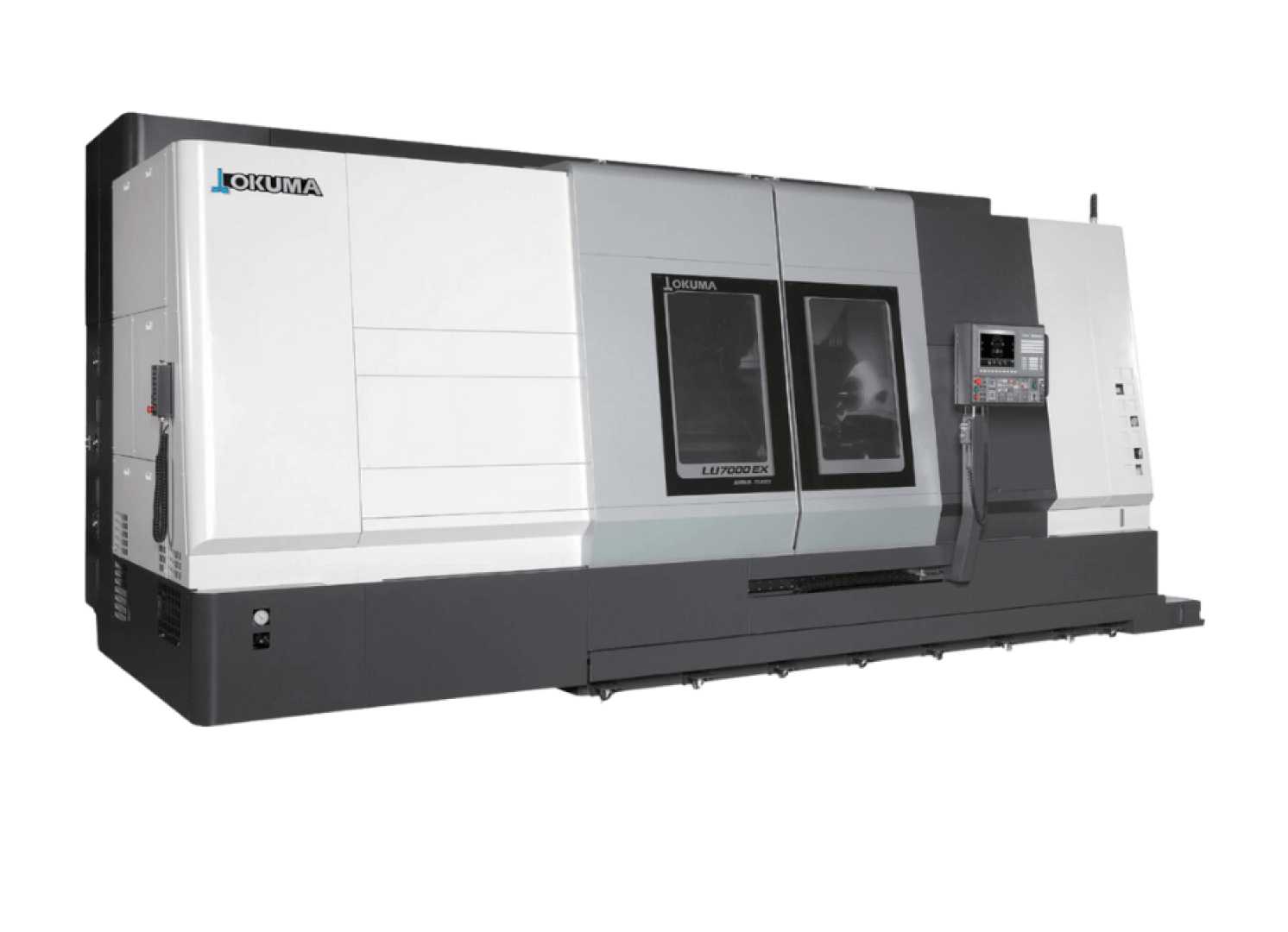

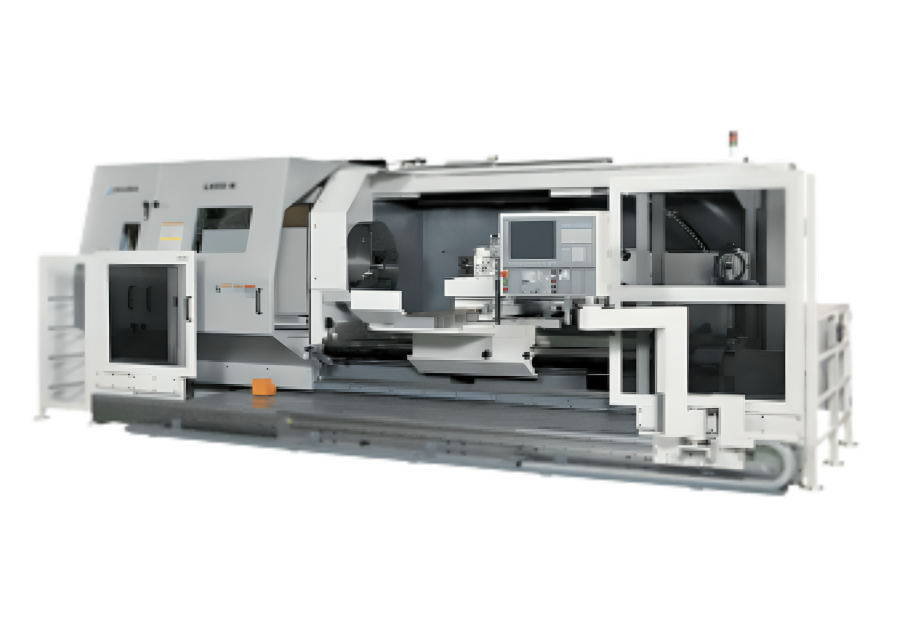

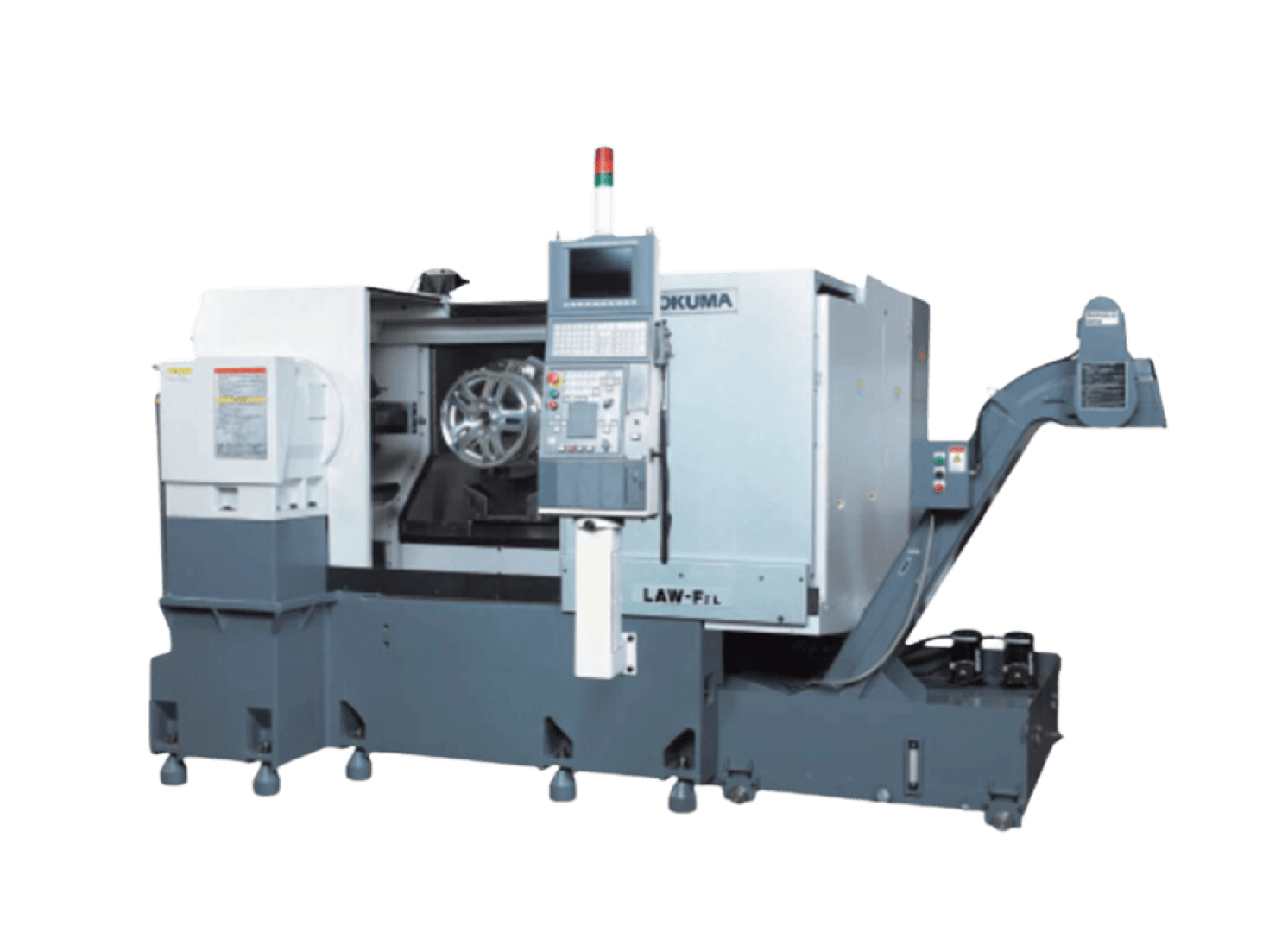

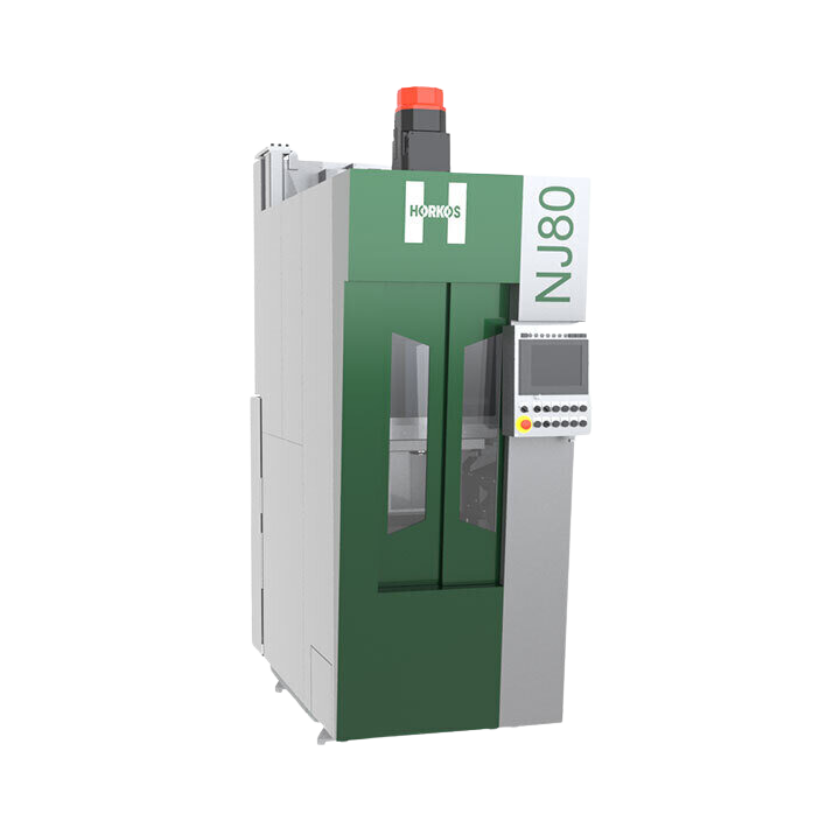

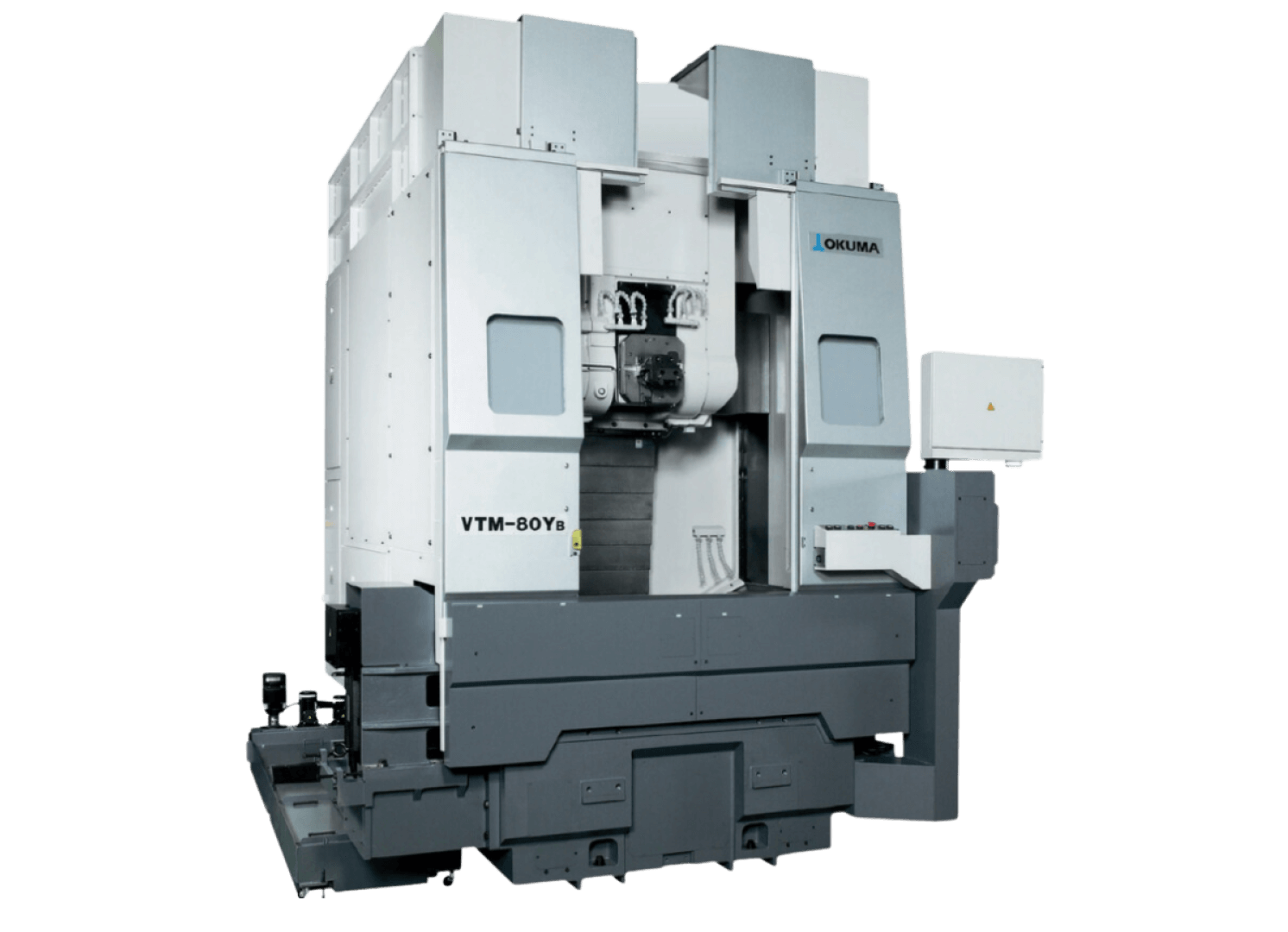

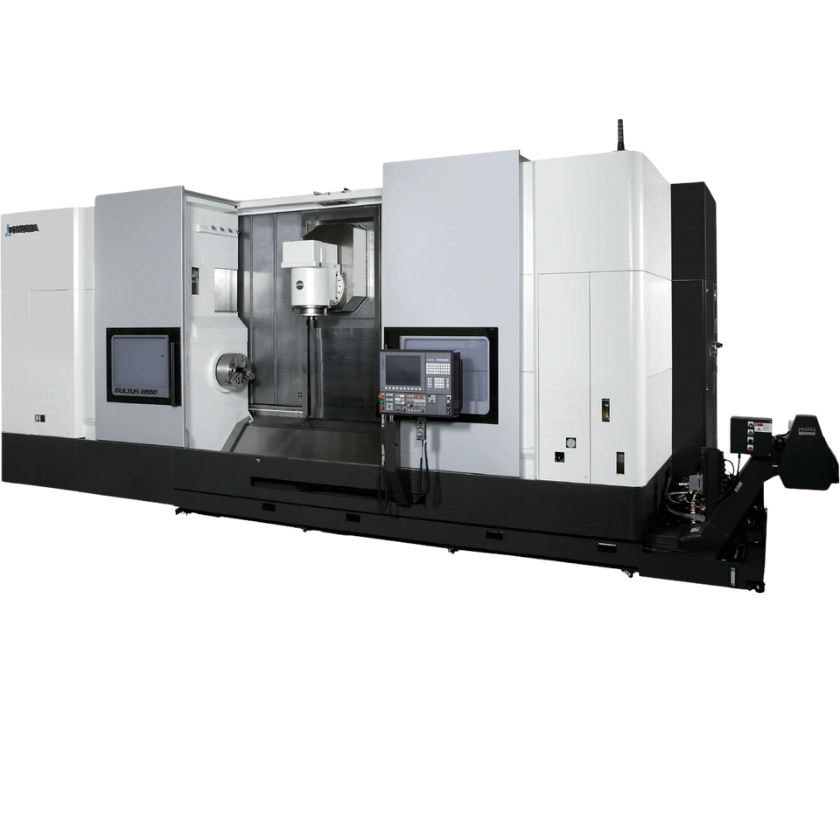

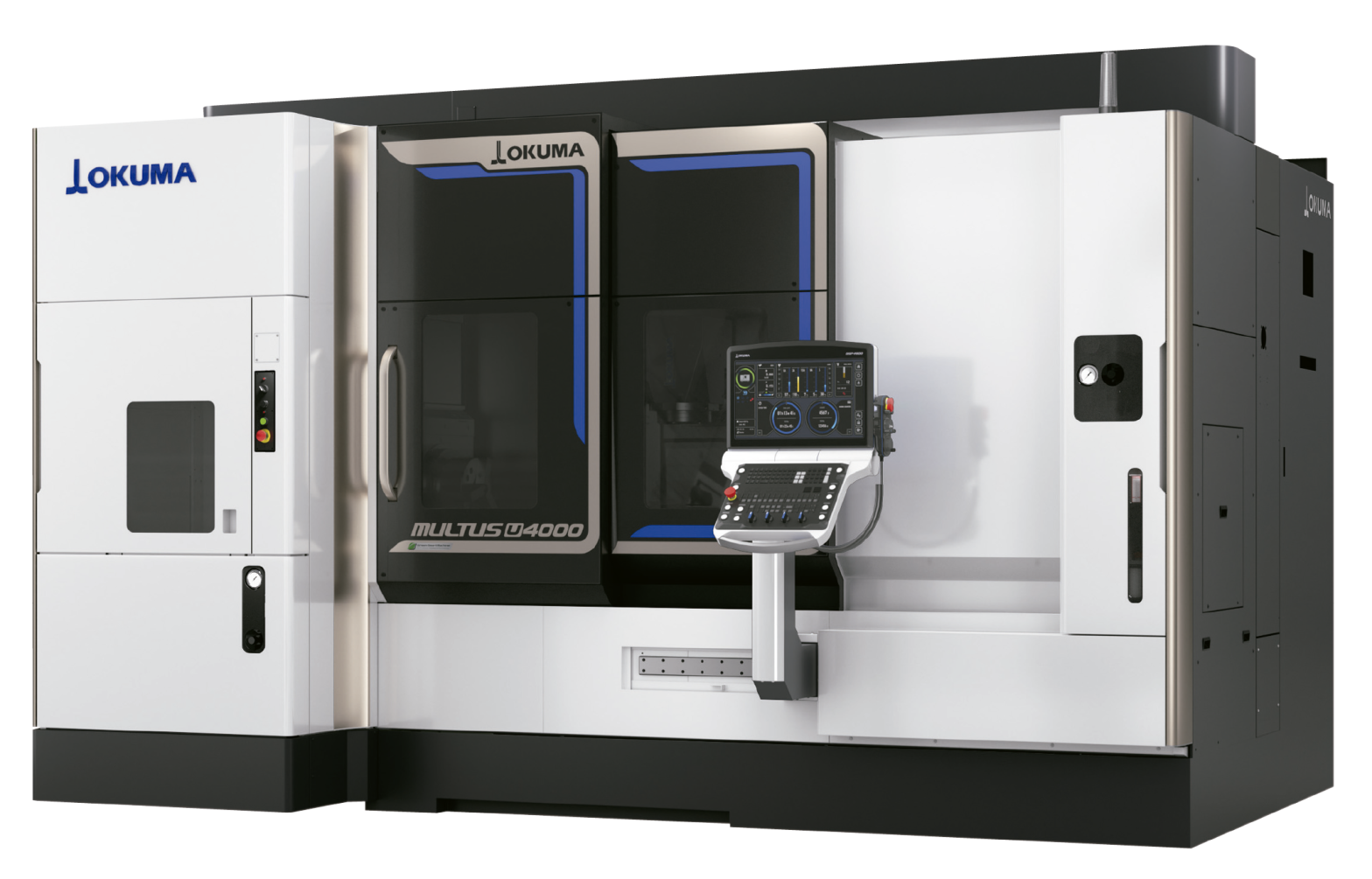

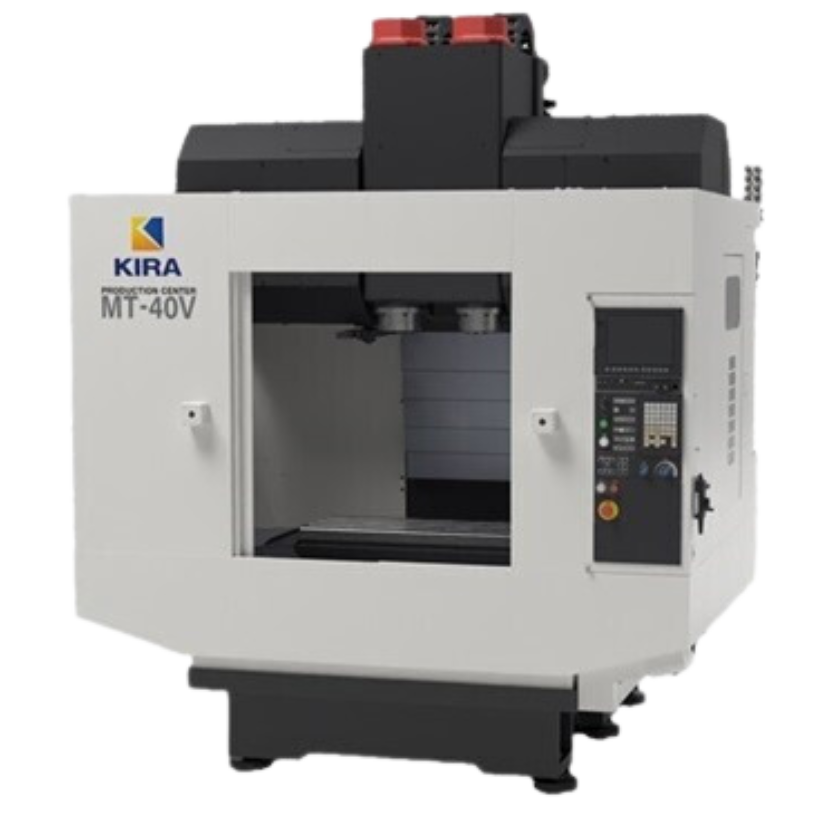

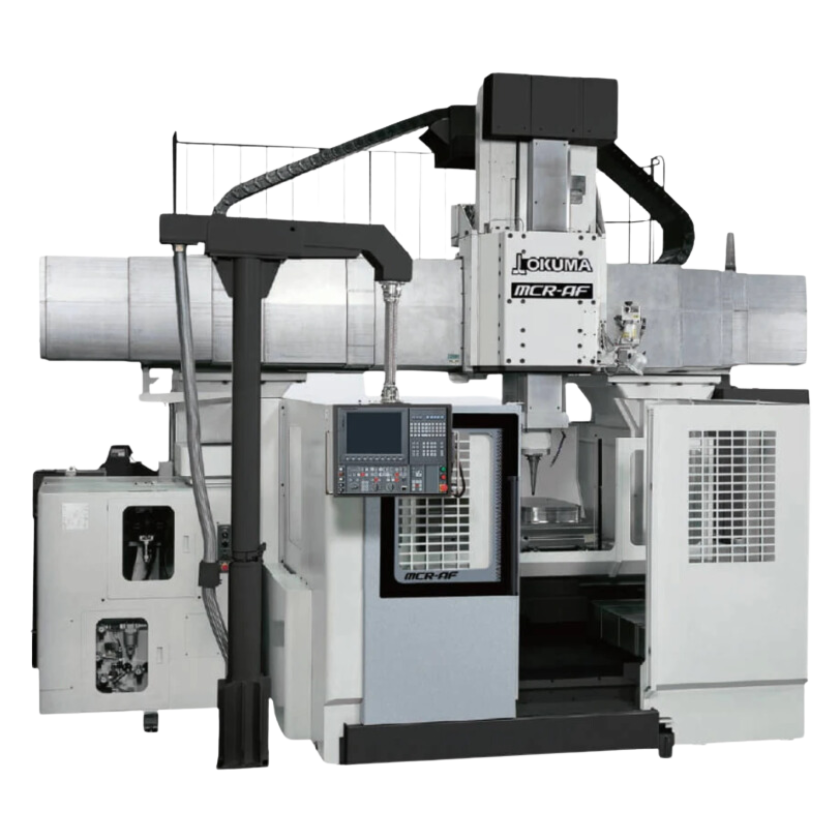

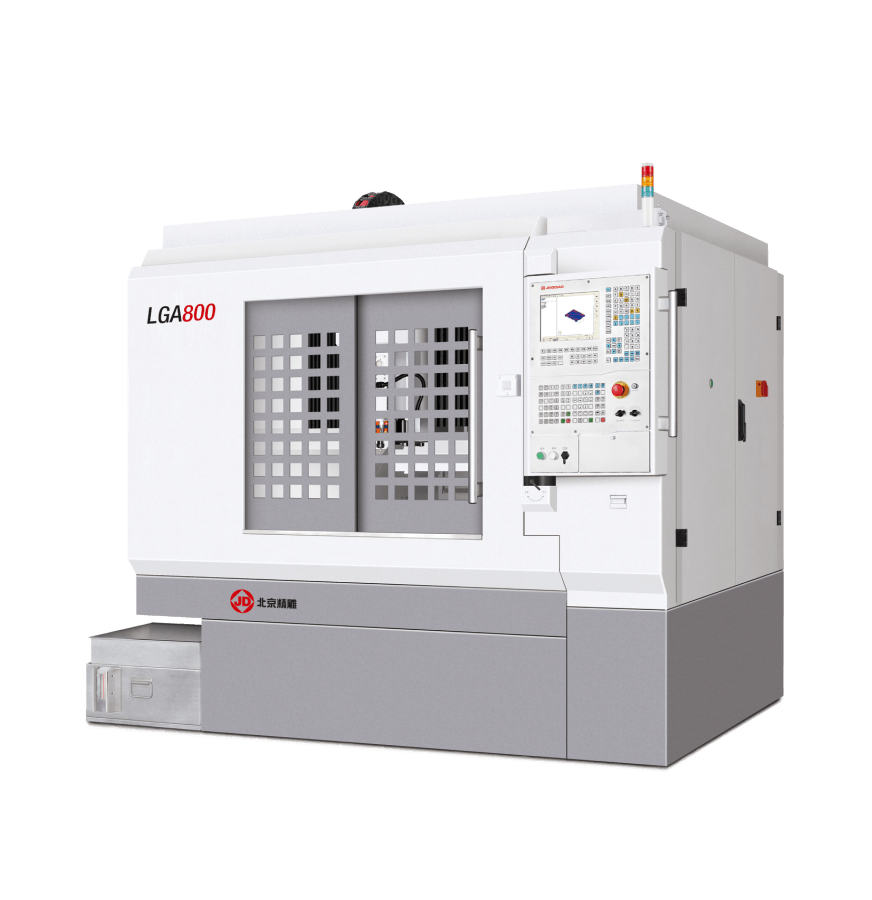

Combinaciones frecuentes para mejorar tus procesos en Tornos CNC, Centros de Maquinado CNC y demás Equipo para Mecanizado.

Equipe y maximice la productividad de sus Máquinas CNC con soluciones integrales

Creación y desarrollo de automatización industrial a la medida de sus necesidades