We design engineering solutions that are specifically tailored to your business.

Leaders in our area, we develop an action plan to offer the desired result.

A critical aspect of customer service is ensuring you have the resources you need to optimize your respective operations.

We are leaders in our area of expertise, which allows us to put together a plan of action to give you the desired result.

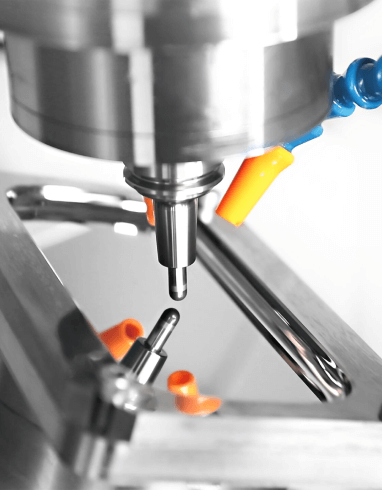

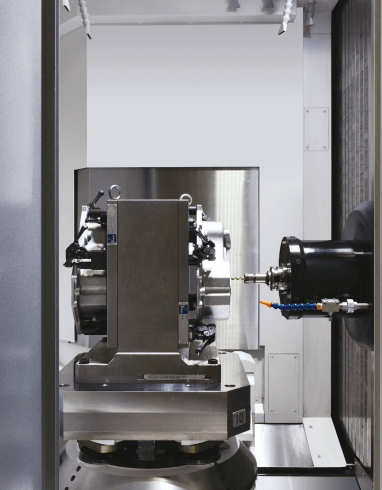

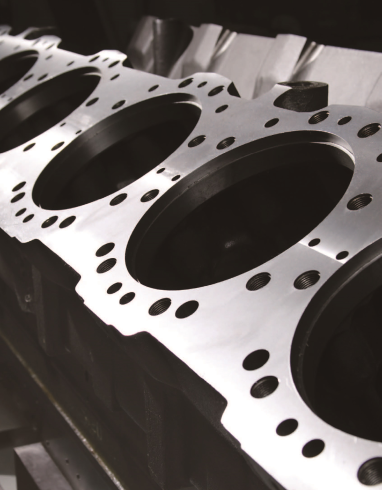

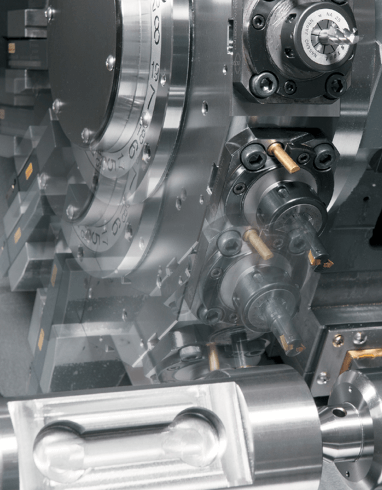

Engineering Systems

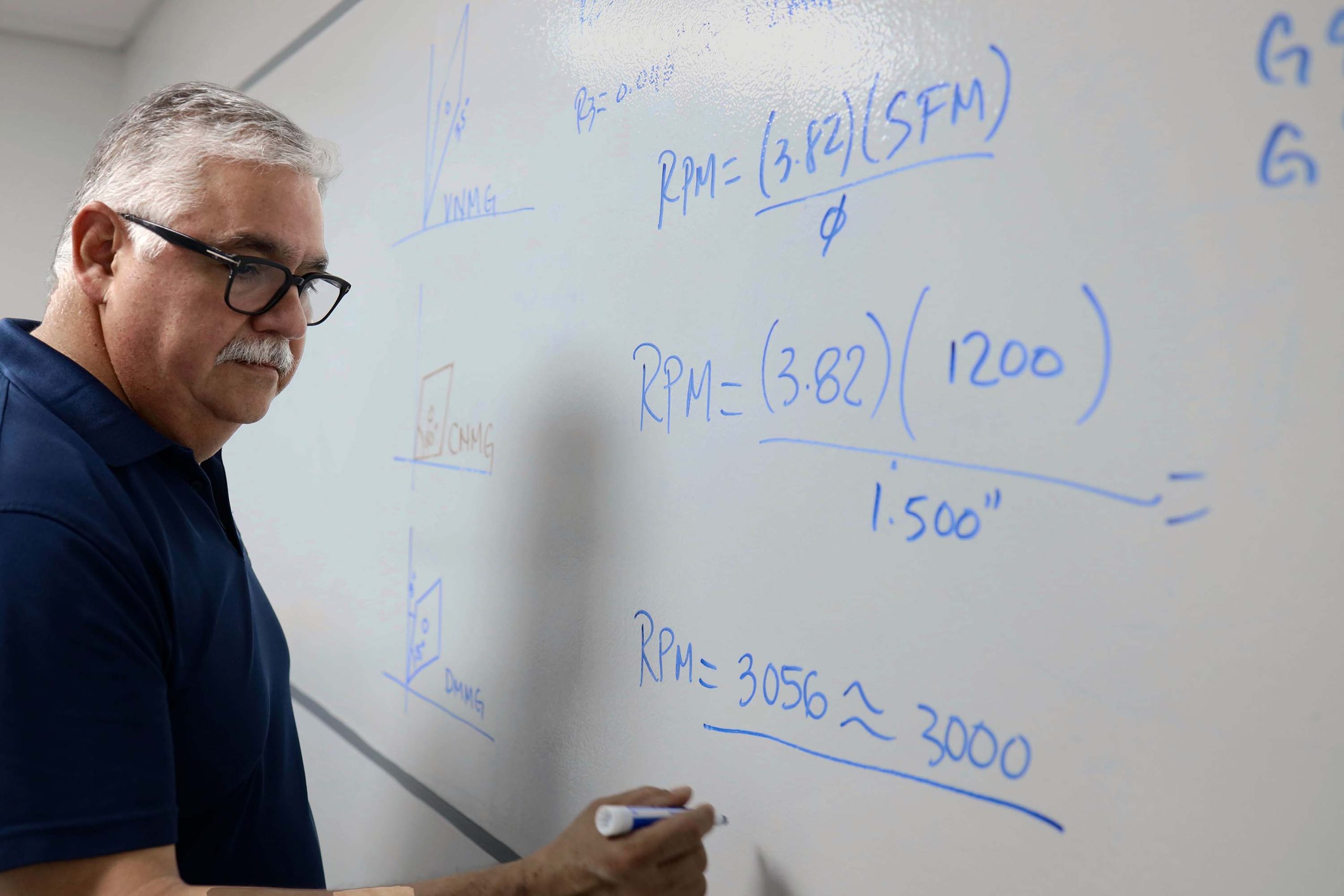

Transforming the development of your company and talent

From basic to advanced training, we provide education and development for your technical staff through virtual and on-site educational programs focused on the CNC Machinery and Metal 3D Printers brands we represent.

01

Engineering Academy

Courses and training

- Operation and programming from basic to advanced level for Machining Centers, Lathes and Grinding Machines

- IGF and AOT interactive programming

- Programming and calibration of measurement systems.

- Programming and alignment of bar feeders.

- Pivot calibration on 5-axis machines

- Operation and programming of (3+1) / (3+2) axes

- Workshop on good practices for CNC Equipment

02

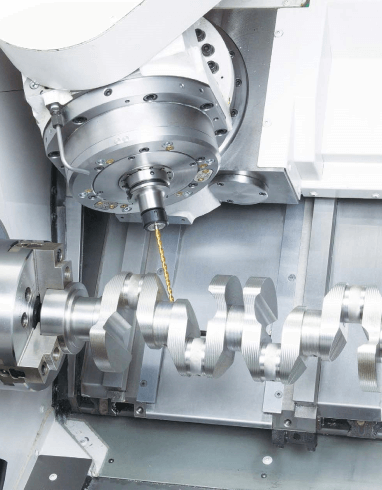

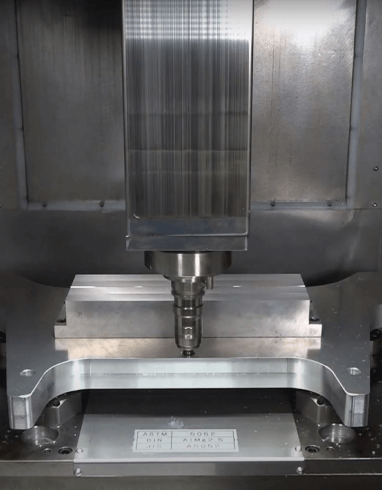

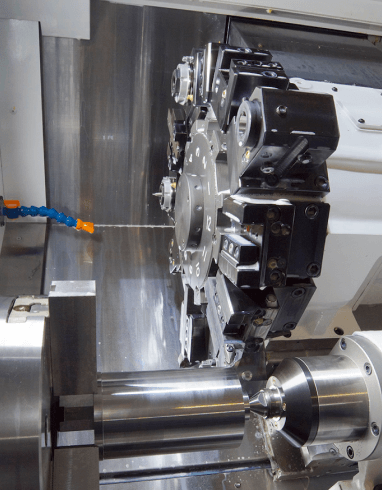

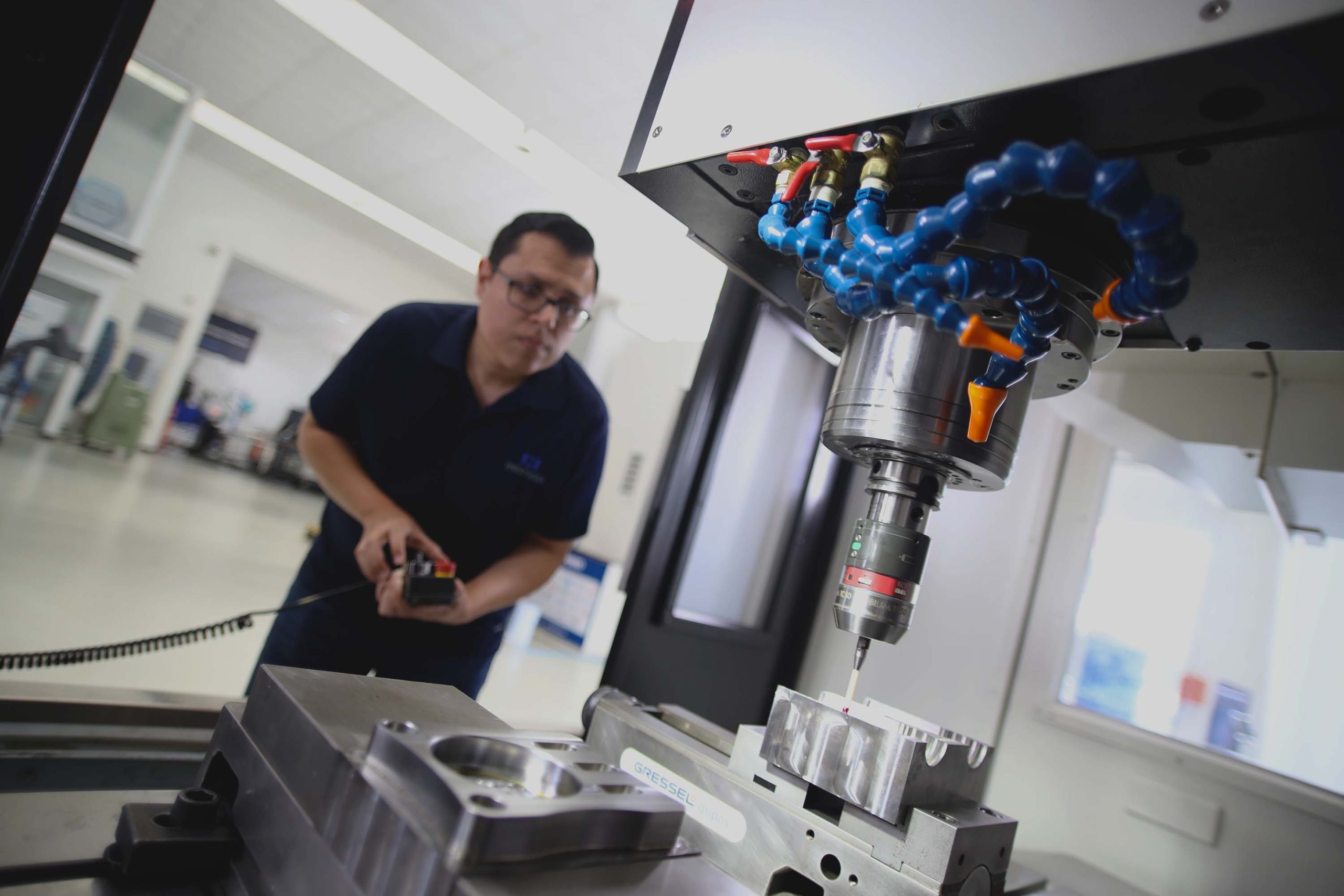

Contract Services

Specialized engineering

- CNC Program Development

- Development of CNC machining processes

- Optimization of machining cycle time

- Poka-yoke implementation

- Advice on the selection of cutting-edge clamping and tooling.

- CMM programming and measurement

- SPC Analysis (CPK)

- CNC machine set-up

03

Service & Support

36 years of experience at your disposal

Our highly specialized engineers are at your disposal at: (+52) 81.8131.3199 and [email protected], contact us for an agile and efficient response.

We are here to help you. Get in touch.

Wait a moment, your message is being sent