Technology | 11.06.2024

OSP-P500: Okuma’s control that reinvents the industry

By: HEMAQ

11.06.2024

Share

Okuma CNC presents: As part of the 2024 edition of ExpoMaq, an event that took place from June 18-20 of this year, we were fortunate and proud to carry out the exclusive presentation for Latin America of the newest in CNC Technology: the new CNC control from Okuma, the long awaited OSP-P500.

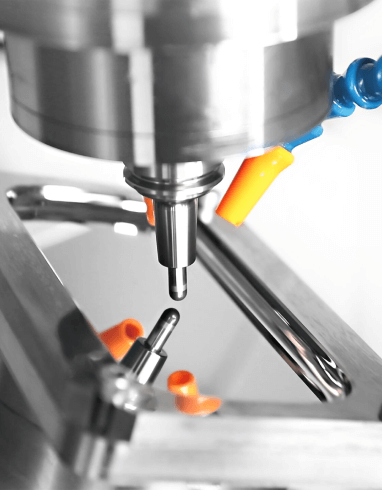

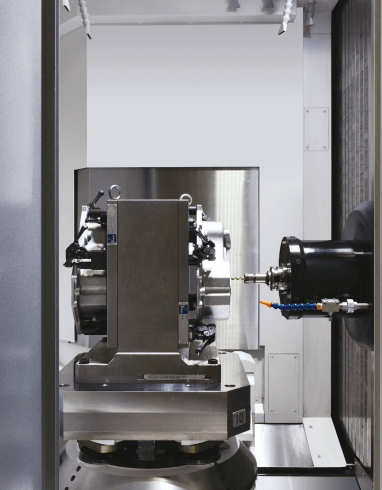

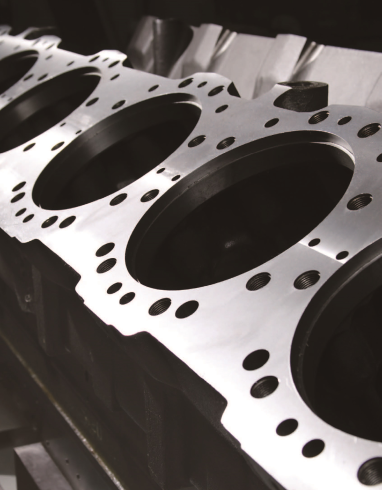

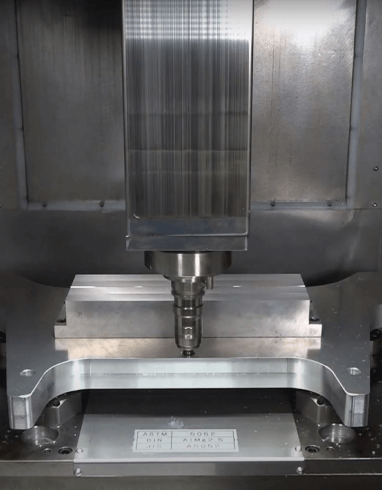

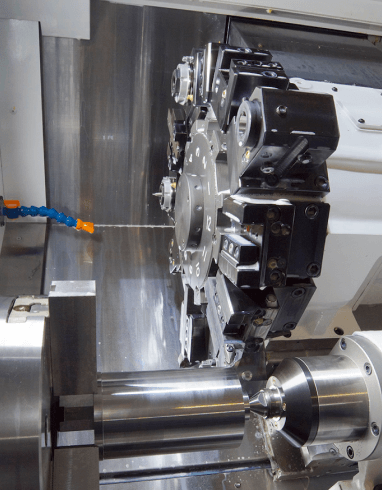

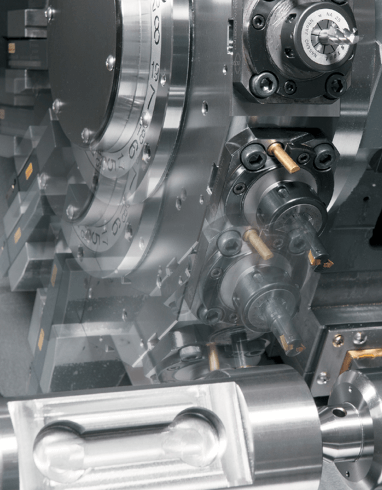

Designed to be the exemplar of the new generation of CNC controls in the metalworking industry, the Okuma CNC OSP-P500 has much greater processing power, enabling the execution of various intelligent technologies, system monitoring and cycle time optimization for Okuma CNC machine tools.

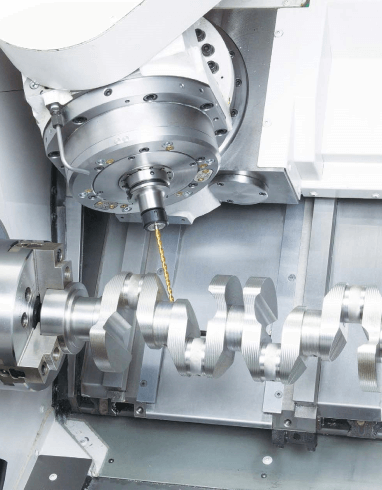

New features and options include: increased processing power to run different applications simultaneously; 15“ or 21.5” display; and the implementation of the Smart OSP Operation system, which allows for simplified use of the control with conversational programming. In addition, its Digital Twin technology enables the operator to verify the machining program, tool displacement and measure interferences before starting to machine thanks to its technology that replicates CNC machining virtually.

Okuma’s unique Digital Twin CNC technology allows CNC machining to be prepared in advance from the office, known as front loading. Thus, the physical setup time of the CNC Equipment can be reduced by digitally simulating the next parts while the machining already started continues. In addition, when a problem occurs on the shop floor, it can be quickly resolved on site without the need to return to the office.

OKUMA CNC

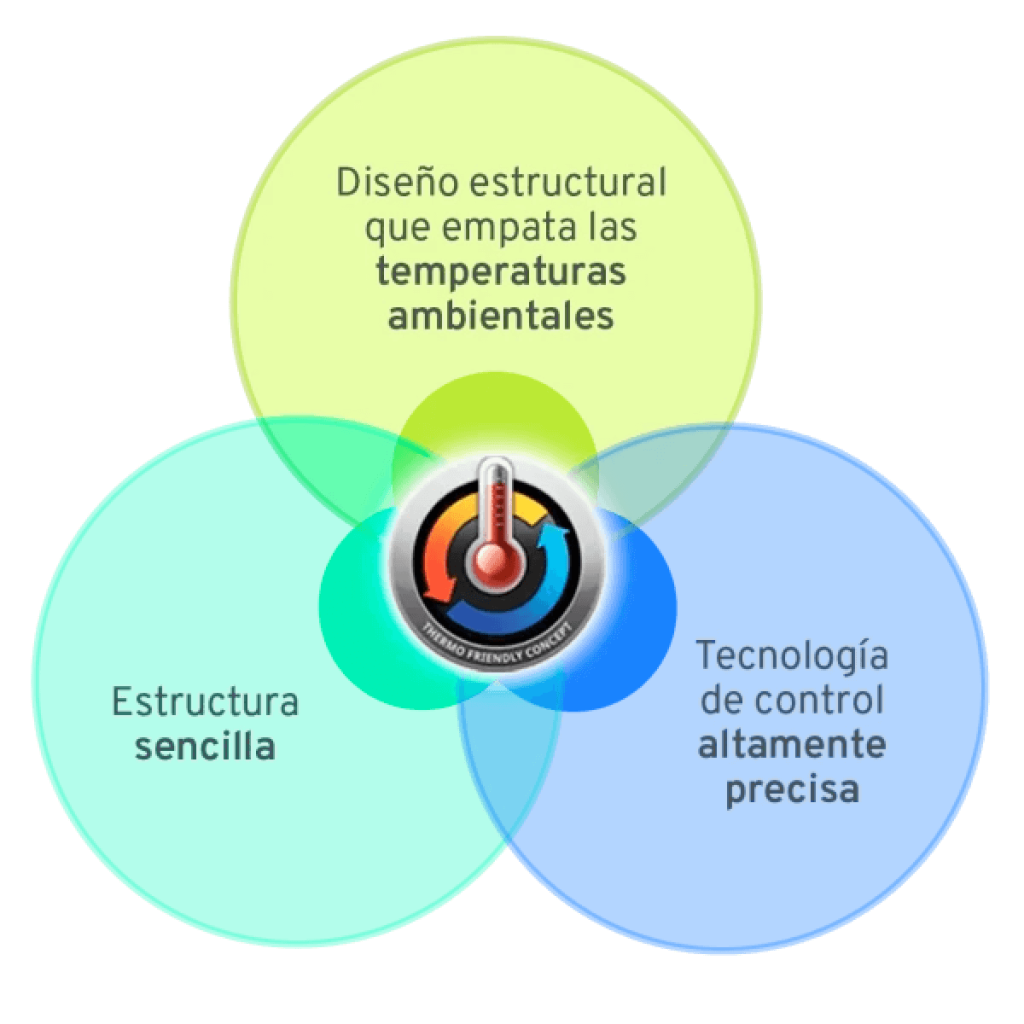

In addition, the new OSP integrates Okuma CNC’s ECO Suite Plus technologies, which facilitate efficient machining while reducing the energy consumption of various equipment systems; allowing for shorter warm-up times, electrical energy savings and effective monitoring of the various CNC machine tool operations.